garrett83

NAXJA Forum User

- Location

- Valencia, ca

No progress today but Vanimal came trough big time by setting me up with some 4" lift coils!!

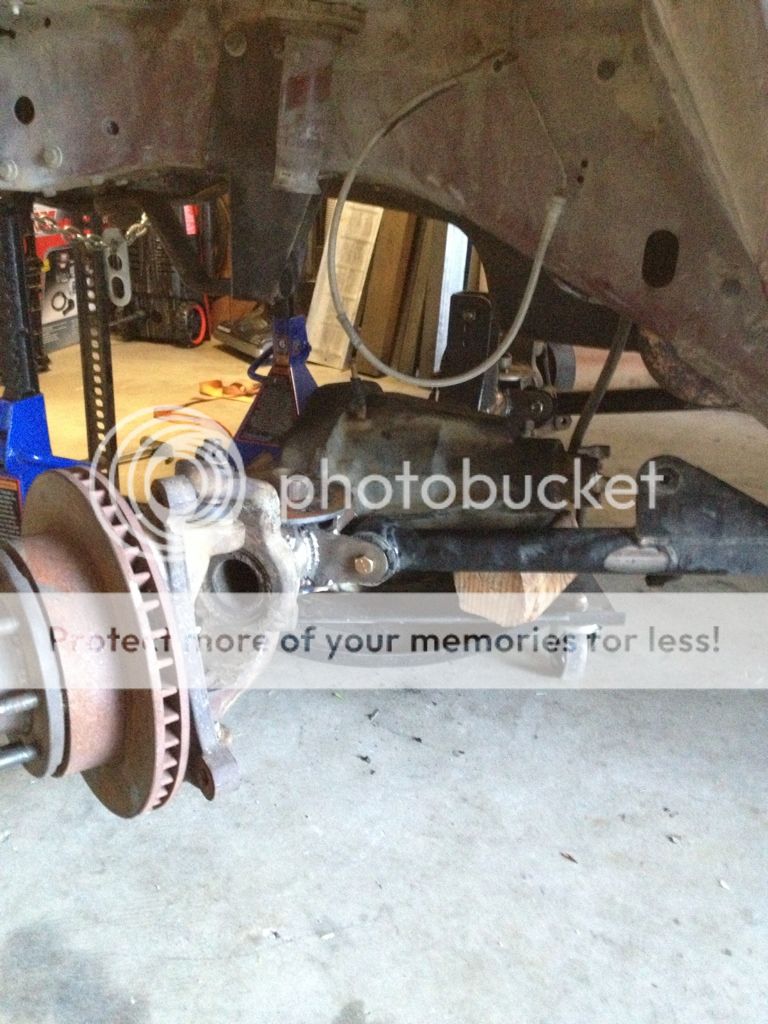

This is the pic of my 8" coil under full weight vs the 4" coil. 8" coil is still an inch taller compressed!!

Anyhow, I'm getting some stock leafs tomorrow so I can build a leaf pack to bring the rear down to a more user friendly height.

This is the pic of my 8" coil under full weight vs the 4" coil. 8" coil is still an inch taller compressed!!

Anyhow, I'm getting some stock leafs tomorrow so I can build a leaf pack to bring the rear down to a more user friendly height.