-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

beater!

- Thread starter ehall

- Start date

- Location

- Southern Maryland

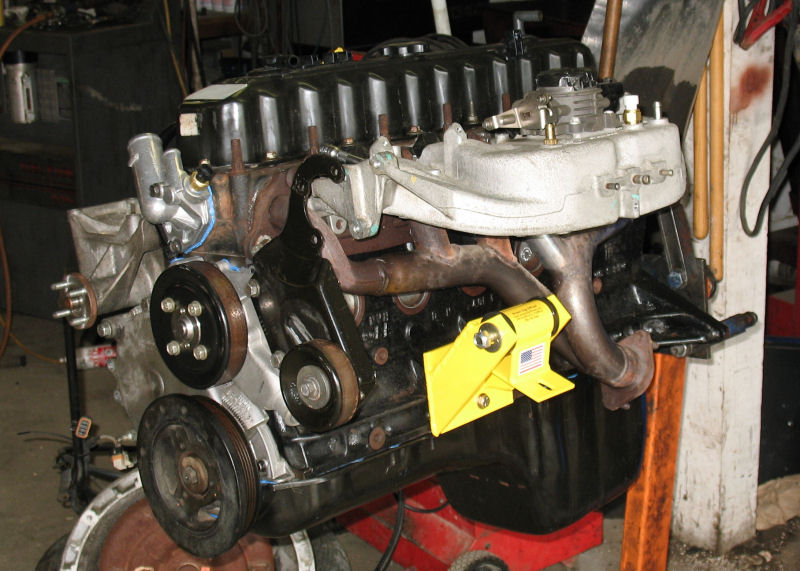

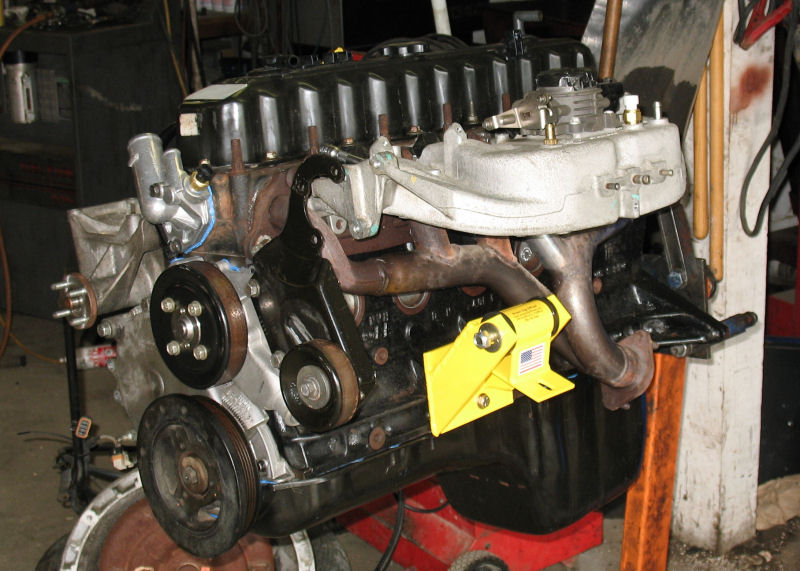

Got the tstat, water housing and water pump replaced. The hard-line from the water pump to the heater valve was rusted pretty bad so I flapped it down and repainted it too. Also got left side of the engine clean, removed the old injectors, replaced the '99 throttle body with a '91 generation 83-mm bored throttle body, and got the browndog replacement mount brackets installed.

I went back to the reclamation house and picked up an AW4 out of a '94 XJ (same generation as mine), with 71k miles for $200 (they are trying to get rid of 10-year-old crap in their warehouse... lucky me!). I started cleaning it up, changing the filter, etc., and noticed that it was leaking from the output shaft, so I am going to have the shop replace both of the seals on the thing for good measure. Good news is that it still had some of the cooler lines on it, so it is 71k miles with cooler.

I am supposed to pickup the 242 on Sunday, and am supposed to get the Thorley headers on Monday, then we will start pulling the old junk out and putting the new junk in.

I went back to the reclamation house and picked up an AW4 out of a '94 XJ (same generation as mine), with 71k miles for $200 (they are trying to get rid of 10-year-old crap in their warehouse... lucky me!). I started cleaning it up, changing the filter, etc., and noticed that it was leaking from the output shaft, so I am going to have the shop replace both of the seals on the thing for good measure. Good news is that it still had some of the cooler lines on it, so it is 71k miles with cooler.

I am supposed to pickup the 242 on Sunday, and am supposed to get the Thorley headers on Monday, then we will start pulling the old junk out and putting the new junk in.

OverlandZJ

NAXJA Member # 101

- Location

- Bristol,PA

It's coming along nicely Eric! See ya sunday..

- Location

- Southern Maryland

Started tearing the old junk out today, but didn't get done before the shop had to close

We did a leakdown test before starting, just to see what the old motor was like. With 100 lb of input pressure, this is what we got:

#1 38

#2 77

#3 66

#4 71

#5 74

#6 64

#1 was pretty bad lol

We did a leakdown test before starting, just to see what the old motor was like. With 100 lb of input pressure, this is what we got:

#1 38

#2 77

#3 66

#4 71

#5 74

#6 64

#1 was pretty bad lol

- Location

- Southern Maryland

Got the old stuff out today. So many little connectors...

Picked up the NP24 from goodfellow OverlandXJ. It looks good, with a build date of Sept 91 so it is the same year as my jeep probably. It's already bolted up to the AW4 so no surprises there.

goodfellow OverlandXJ. It looks good, with a build date of Sept 91 so it is the same year as my jeep probably. It's already bolted up to the AW4 so no surprises there.

When I got back home I found the headers I'd ordered--these are the old Mike Leach Mopar headers currently produced by Doug Thorley as I understand it. I had ordered the ceramic but I think they sent chrome. They sure are purdy:

The headers will go in tomorrow along with the rest of the newer parts, so hopefully we will get this done before the end of the week.

Picked up the NP24 from

goodfellow OverlandXJ. It looks good, with a build date of Sept 91 so it is the same year as my jeep probably. It's already bolted up to the AW4 so no surprises there.

goodfellow OverlandXJ. It looks good, with a build date of Sept 91 so it is the same year as my jeep probably. It's already bolted up to the AW4 so no surprises there.

When I got back home I found the headers I'd ordered--these are the old Mike Leach Mopar headers currently produced by Doug Thorley as I understand it. I had ordered the ceramic but I think they sent chrome. They sure are purdy:

The headers will go in tomorrow along with the rest of the newer parts, so hopefully we will get this done before the end of the week.

Crabapple

NAXJA Forum User

- Location

- Greensboro, North Carolina

Too purdy to put in the jeep! The build is lookin great!

Veeb0rg

NAXJA Forum User

- Location

- Glen Burnie, MD

damn that header is all sorts of purdy..

- Location

- Southern Maryland

Got the rest of the parts installed today. One of the guys in my local club says the headers are ceramic, that they have a polished ceramic coating that is used on headers now.

Also got the four-nozzle injectors installed. They do not have slots for the clips but the rail clamps them in nice and tight. Hopefully these and the Accel coil will let me run a substantially bigger gap later.

Also sealed up some leaks in the firewall. I learned a neat trick on the Cadillac forums, which is to use Tonic Water and a black light to find leaks--the quinine in the tonic water reflects the ultraviolet. I had leaks at the shifter cable and the accelerator cable, and the foam rubber around the heater hoses was also rotted out, but I was able to fill everything with some GE black silicon sealant. If it's holding up tomorrow we'll start reinstalling stuff.

Also got the four-nozzle injectors installed. They do not have slots for the clips but the rail clamps them in nice and tight. Hopefully these and the Accel coil will let me run a substantially bigger gap later.

Also sealed up some leaks in the firewall. I learned a neat trick on the Cadillac forums, which is to use Tonic Water and a black light to find leaks--the quinine in the tonic water reflects the ultraviolet. I had leaks at the shifter cable and the accelerator cable, and the foam rubber around the heater hoses was also rotted out, but I was able to fill everything with some GE black silicon sealant. If it's holding up tomorrow we'll start reinstalling stuff.

MT Mike

NAXJA Forum User

- Location

- Helena, MT

- Location

- Southern Maryland

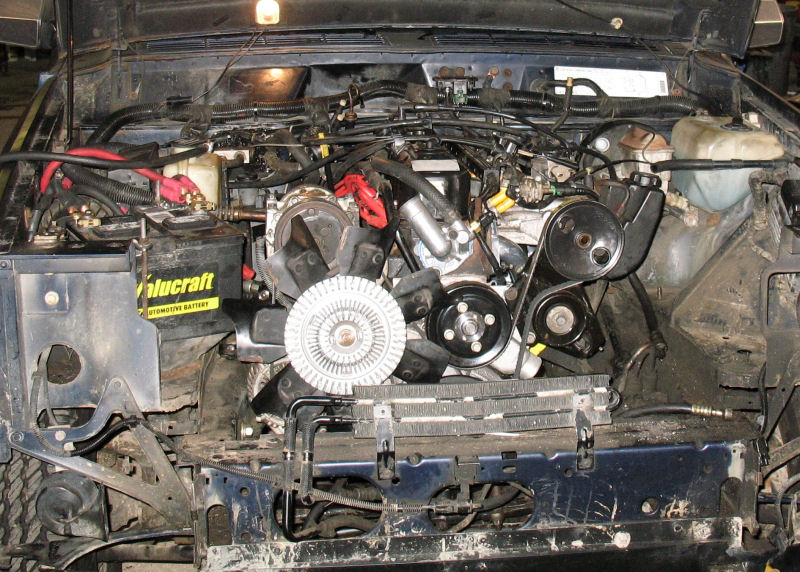

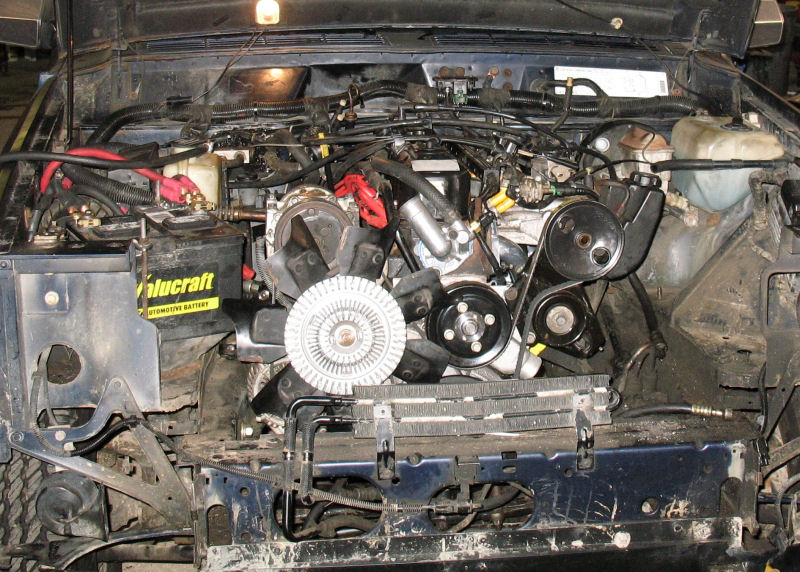

The new powertrain is in the Jeep as of yesterday. Today we plugged up the wires, rebuilt the vacuum harness, setup the power steering, etc etc. Current status is that it will crank but not start. There is still a lot to do anyway (driveshafts, A/C hoses, grille, etc). Here are some pics of the engine going in and after it was mostly hooked up.

Yesterday I picked up some breather caps from the local GM dealership and extended the transmission and transfer case breather lines up the dipstick. I am going to try to route the rear axle breather up into the D-pillar after I get it home.

The shop is closed til Monday.

Yesterday I picked up some breather caps from the local GM dealership and extended the transmission and transfer case breather lines up the dipstick. I am going to try to route the rear axle breather up into the D-pillar after I get it home.

The shop is closed til Monday.

OverlandZJ

NAXJA Member # 101

- Location

- Bristol,PA

Eric, was the trans bolted up and installed with engine or afterwords?

When i swapped a motor in my old 88 i made the mistake of pinching the CPS harness between block and bellhousing cutting the signal. Easy enough to check visually.

Could the dizzy be dropped in 180 out? I'v done that one too..

When i swapped a motor in my old 88 i made the mistake of pinching the CPS harness between block and bellhousing cutting the signal. Easy enough to check visually.

Could the dizzy be dropped in 180 out? I'v done that one too..

- Location

- Southern Maryland

It was 9pm by the time I got the serp belt installed and the shop owner had his shoes off and was yawning a lot. I figured it was good enough that it was cranking.

I think the CPS is unplugged. I checked to make sure the wire was unharmed earlier today, and moved the connector up top to hook it up, but I don't think I ever got around to it.

I think the CPS is unplugged. I checked to make sure the wire was unharmed earlier today, and moved the connector up top to hook it up, but I don't think I ever got around to it.

OverlandZJ

NAXJA Member # 101

- Location

- Bristol,PA

:laugh3:

I thought of that but thought... surely thats the 1st thing he checked. Must kill ya to have to leave it sit the next few days though.

I thought of that but thought... surely thats the 1st thing he checked. Must kill ya to have to leave it sit the next few days though.

- Location

- Southern Maryland

There's 20 things left to do, and I know "connect the CPS" was right up there. I did the O2 sensor, then the starter and alternator, and then got on to the vacuum and power steering. I kept looking at CPS connector on top of intake all day "oh yeah, plug that up"

- Location

- Southern Maryland

Well the good news is the engine fired right up once I plugged the CPS into the harness :looser:

Got everything bolted back on and took it for a test, but the bolted-up muffler fell out of the clamp about 20 feet down the drive :looser: I'm hoping to get a Borla cat-back next month so I didn't want the old junk welded back on, but we had to tack it to get it to stick in place

Now the problem is that the heep is grinding and binding whenever it is under load in motion. I have to do some debugging to figure this out. I'll make a post in OEM tech.

Got everything bolted back on and took it for a test, but the bolted-up muffler fell out of the clamp about 20 feet down the drive :looser: I'm hoping to get a Borla cat-back next month so I didn't want the old junk welded back on, but we had to tack it to get it to stick in place

Now the problem is that the heep is grinding and binding whenever it is under load in motion. I have to do some debugging to figure this out. I'll make a post in OEM tech.

- Location

- Southern Maryland

The compression numbers look great. With 100 lb of input pressure, the leakdown tester reported the following:

#1 95

#2 99/100

#3 99/100

#4 96

#5 99/100

#6 96

That's practically new condition.

Here's a pic of the new engine fully installed. That nasty engine bay sure does hide it well.

I did 5-90's wiring harness which you can kind of see next to the battery. There is a big ground strap between the battery and fender, the battery and engine block, and the engine and firewall. There are positive wires between the battery and alternator (with a 150 amp fuse instead of the cheap fusible link), battery and PDC, and the battery and starter. Very nice voltage levels in the jeep now--the interior lights are much brighter lol.

#1 95

#2 99/100

#3 99/100

#4 96

#5 99/100

#6 96

That's practically new condition.

Here's a pic of the new engine fully installed. That nasty engine bay sure does hide it well.

I did 5-90's wiring harness which you can kind of see next to the battery. There is a big ground strap between the battery and fender, the battery and engine block, and the engine and firewall. There are positive wires between the battery and alternator (with a 150 amp fuse instead of the cheap fusible link), battery and PDC, and the battery and starter. Very nice voltage levels in the jeep now--the interior lights are much brighter lol.

- Location

- Southern Maryland

I was planning to get the Borla catback to finish the exhaust but when I called to order it, I found out Borla was out of inventory and nobody would have it for another couple of months at least. So I bought their 2.25" Turbo XL standalone muffler instead

Also bought a new factory tailpipe hangar from the stealership, $16 I think

It's all bolted up along with a new Walker tail pipe, but not welded yet. It's very quiet at cruising speed, and makes a roar instead of a rumble at low speed torque. It also feels kind of softer than before. I will probably switch to a 2" tailpipe before welding so that I get a little more action at the bottom end. At least it's not rattling against the leafs anymore

Also bought a new factory tailpipe hangar from the stealership, $16 I think

It's all bolted up along with a new Walker tail pipe, but not welded yet. It's very quiet at cruising speed, and makes a roar instead of a rumble at low speed torque. It also feels kind of softer than before. I will probably switch to a 2" tailpipe before welding so that I get a little more action at the bottom end. At least it's not rattling against the leafs anymore

- Location

- Southern Maryland

Today I got the exhaust finished. Not much to look at but it feels and sounds good. The setup is 2.5" Thorley headers into a 2.25" downpipe, with same sized cat and Borla muffler, then dropping down into a 2" tailpipe. The switch to 2" really boosted the torque at about 2000 RPM, whereas the 2.25" had the most power at around 3000 RPM.

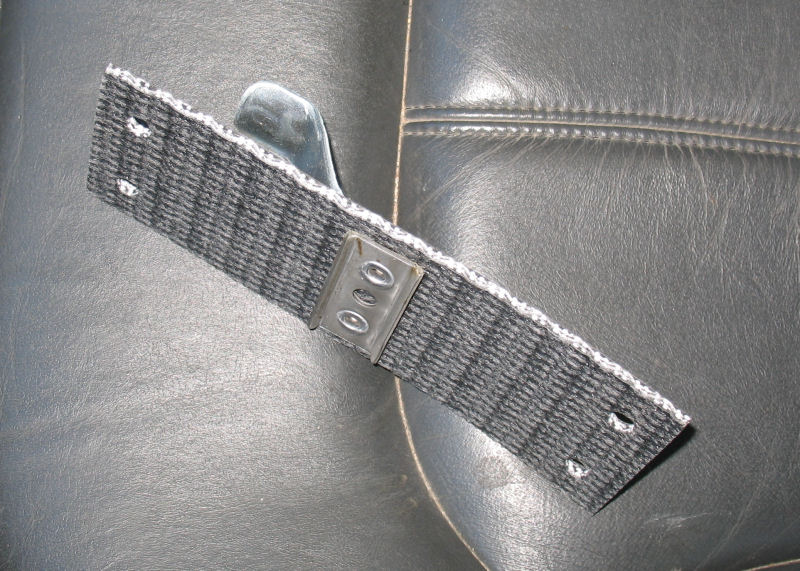

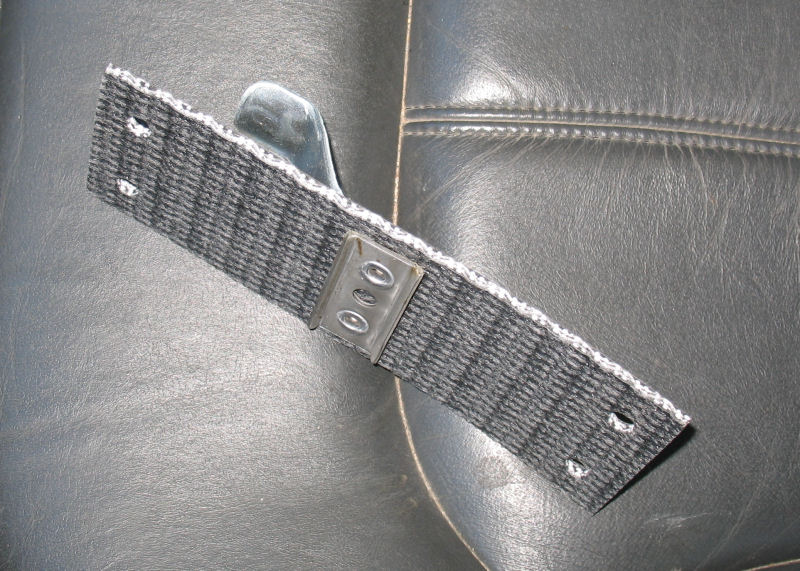

Since the muffler is stainless (non magnetic) the engine shop didn't think they could weld it with their setup so we used some large band clamps that seal everything up nice and tight (about $12 each). I'm really happy with the tone and torque so I will get an exhaust shop to weld it up after I fit a gas tank skid.

This completes the engine swap.

Since the muffler is stainless (non magnetic) the engine shop didn't think they could weld it with their setup so we used some large band clamps that seal everything up nice and tight (about $12 each). I'm really happy with the tone and torque so I will get an exhaust shop to weld it up after I fit a gas tank skid.

This completes the engine swap.

- Location

- Southern Maryland

When we were messing with the powertrain, I noticed that the left u-joint on the D30 was pretty nasty looking. I could hear it kind of whistle and whine while in 2WD as well, and once I started trying to use the AWD on the 242 the u-joint would squeal really bad. Researching into it I found that the '91 had the 260 u-joint, but 95+ supposedly had the 297. I also found out that the TJ D30 also had the same larger joints, and one of the nearby jeepers in the neighboring club had a set of trail spares for sale, so I bought them. This is what they looked like when I got them...

It took about a full day to get the hubs and u-joints off and to get all the barnacles off the shafts, but they cleaned up pretty well

After that, I ordered a pair of Spicer 5-297x u-joints and some cheap hubs from eBay (short-term use only). Everything cleaned up pretty nice

Today I got everything reassembled and installed, and it all went together pretty easily. The shafts are smooth and quiet, and I'm able to use AWD with no problem.

It took about a full day to get the hubs and u-joints off and to get all the barnacles off the shafts, but they cleaned up pretty well

After that, I ordered a pair of Spicer 5-297x u-joints and some cheap hubs from eBay (short-term use only). Everything cleaned up pretty nice

Today I got everything reassembled and installed, and it all went together pretty easily. The shafts are smooth and quiet, and I'm able to use AWD with no problem.

bigalpha

Moderator

- Location

- Tucson, AZ

Wow. Those cleaned up nice. I'll be pulling my shafts soon to replace the u-joints. Looks easy enough.