- Location

- Hammertown, USA

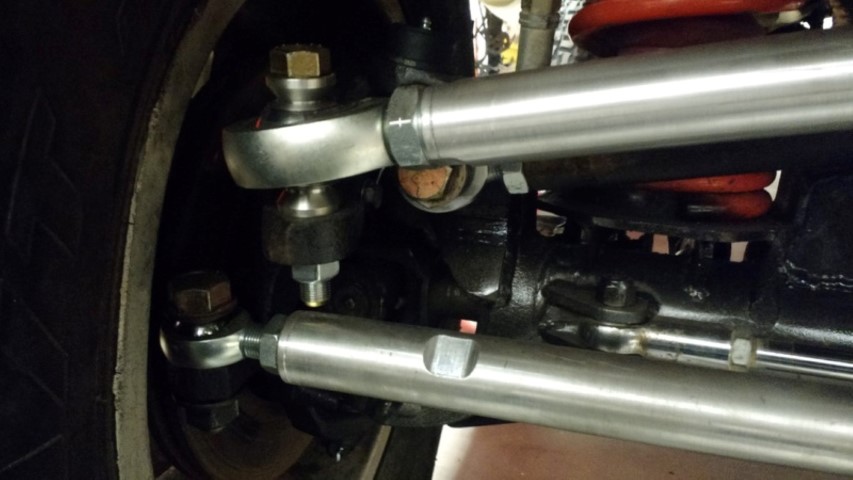

The nose tires on a V-22 are 250 psi. I'm not talking about 235/75/15's. The portable nitrogen cylinder we use has 3000 psi in it.

Do you think I would make that suggestion without knowing what I was talking about?

Many people do just that these days Josh, and he doesn't know who you are. Don't let it get under your skin.