asp

NAXJA Forum User

- Location

- Westport, MA

Some history:

I acquired the XJ in the summer of 2007. It was bone stock with 98k on the ticker.

Then I bought 31s and a rear locker

Then I did a 2" budget boost at the club garage with the help of Ned and Eric.

Then I put a real 3" lift in

Then I wheeled it for a long time and had a lot of fun and didn't really brake much.

Then I put in a SYE, 4.5" lift, 4.56 axles, WJ front brakes, a winch, and a bunch of other good stuff.

I wheeled it a quite a bit on 34's but knew that the body was on borrowed time due to rust in critical parts.

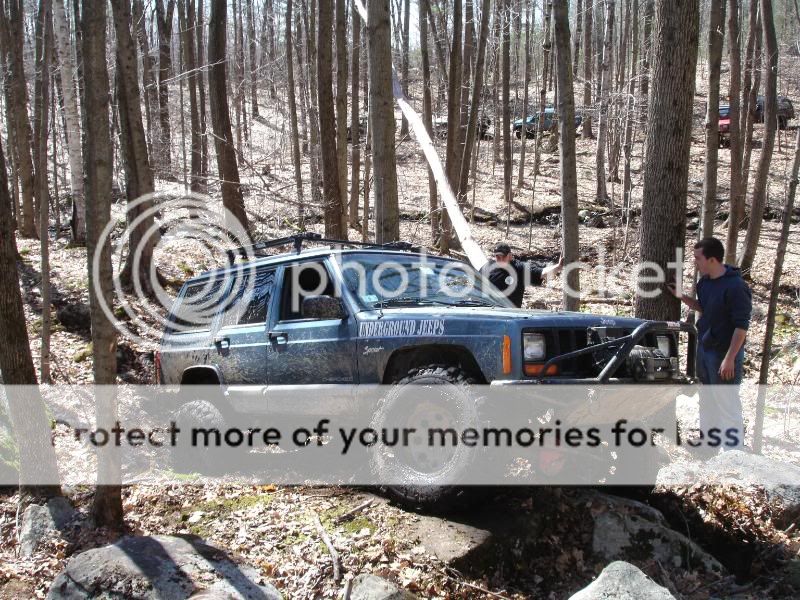

this was steep and really loose. not everyone makes it first try, or at all...

http://s90.photobucket.com/albums/k245/sheepsyj/?action=view¤t=MOV01497.flv

At the 2009 show:

Now I'm all moved into my new house and the build is underway.

The plan is to run about 104-5" wheelbase, NP 231/300 doubler, 4 link rear, 3 link front, the built dana 44's that I already have, hydro assist, cage, and coilovers/airshocks/ori's. (not sure which one yet...)

No, I won't be wheeling for a good little while.

I'm calling it Project Chemotherapy because I'm removing all of my Northeast Cancer. Hopefully when I'm done removing the rust I have something left to work with...

I made a cart for my 110V mig welder too. The bottle is held vertical by a 231 chain. The paint was still wet, otherwise I'd have had the welder in the cart...

I acquired the XJ in the summer of 2007. It was bone stock with 98k on the ticker.

Then I bought 31s and a rear locker

Then I did a 2" budget boost at the club garage with the help of Ned and Eric.

Then I put a real 3" lift in

Then I wheeled it for a long time and had a lot of fun and didn't really brake much.

Then I put in a SYE, 4.5" lift, 4.56 axles, WJ front brakes, a winch, and a bunch of other good stuff.

I wheeled it a quite a bit on 34's but knew that the body was on borrowed time due to rust in critical parts.

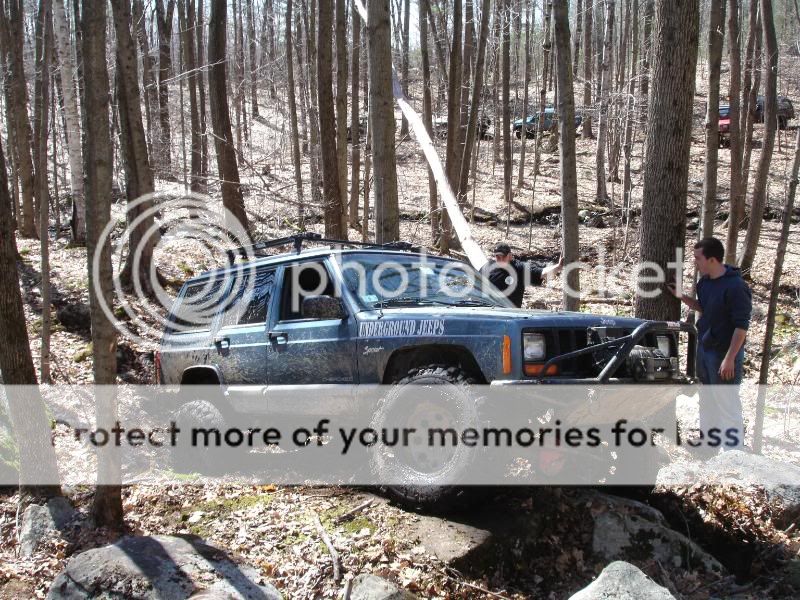

this was steep and really loose. not everyone makes it first try, or at all...

http://s90.photobucket.com/albums/k245/sheepsyj/?action=view¤t=MOV01497.flv

At the 2009 show:

Now I'm all moved into my new house and the build is underway.

The plan is to run about 104-5" wheelbase, NP 231/300 doubler, 4 link rear, 3 link front, the built dana 44's that I already have, hydro assist, cage, and coilovers/airshocks/ori's. (not sure which one yet...)

No, I won't be wheeling for a good little while.

I'm calling it Project Chemotherapy because I'm removing all of my Northeast Cancer. Hopefully when I'm done removing the rust I have something left to work with...

I made a cart for my 110V mig welder too. The bottle is held vertical by a 231 chain. The paint was still wet, otherwise I'd have had the welder in the cart...