I was getting a bit of play in my steering and my Jeep didn't feel quite as stable as it should over bumps on the highway.

After looking at my front end i saw the Rod end at the Pittman arm was bad and had alot of play in it .

I had replaced all of the Rod ends multiple times since i bought this jeep I was using the Lifetime cheap ones from auto zone .

Who cares if they replace them if you have to keep changing them out ?

So the last time i did it i said when they went bad again i would upgrade.

So I Upgraded the steering to a Currie Currectlync Setup and I am VERY happy with it .

I Am also very happy with my Lifetime alignment from Firestone , I have definitely gotten my money out of that deal.

I did a driveway alignment once and it was almost dead on but this is easier and doesn't cost me anymore

Before When I hit a bump on the highway I would get just a second of wobble you could really feel at the steering wheel .

This made sense because i could grab and flex the stock tie rod.

The Steering is SO much tighter and So solid I Don't feel any movement in my steering even on the highway over bumps.

It Just Feels so much better and I feel A LOT safer this thing is way stronger than the stock setup!

I Hadn't bent up a stock setup yet but I heard being locked in the front made it more likely to happen , I am not as worried about it now !

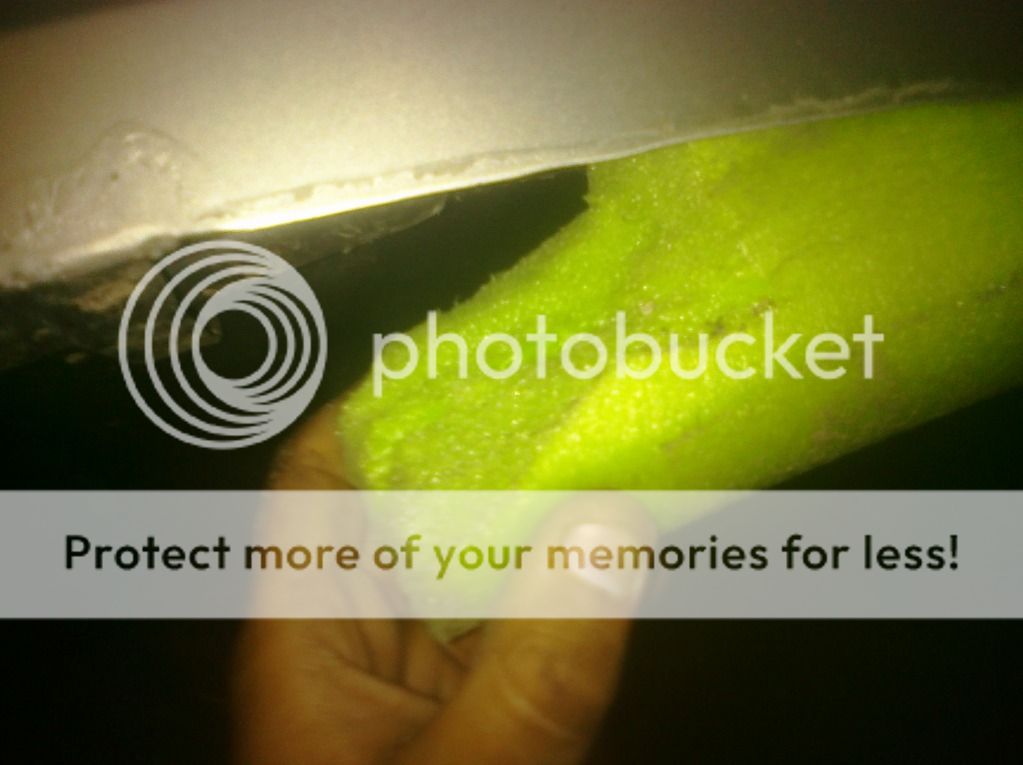

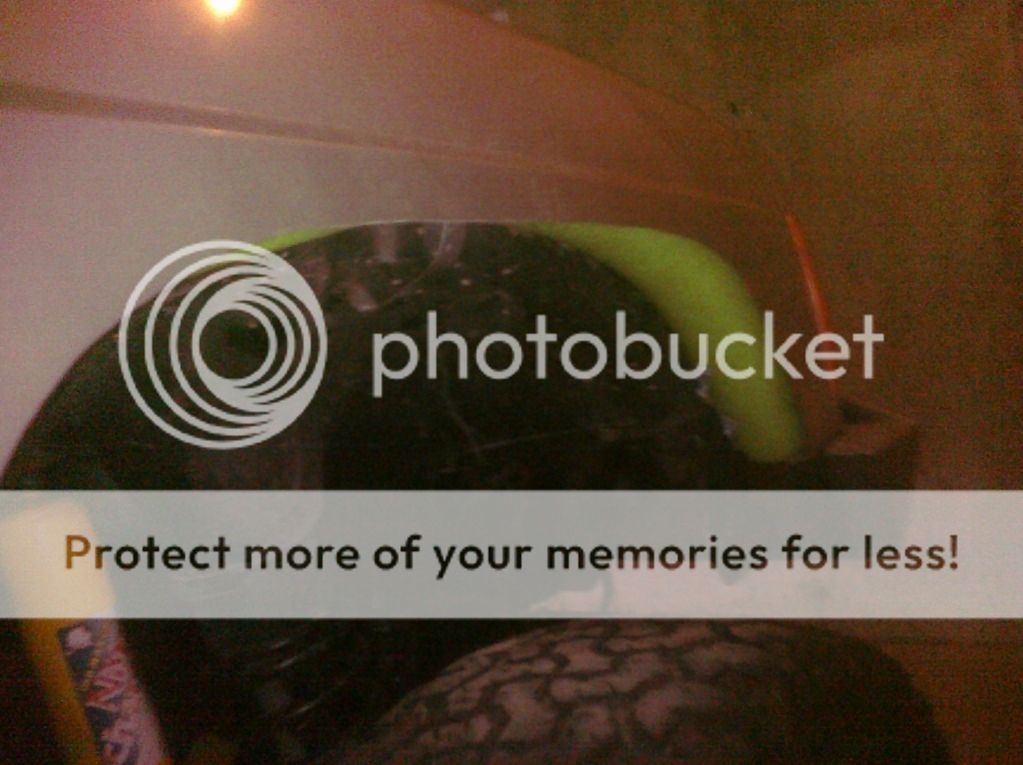

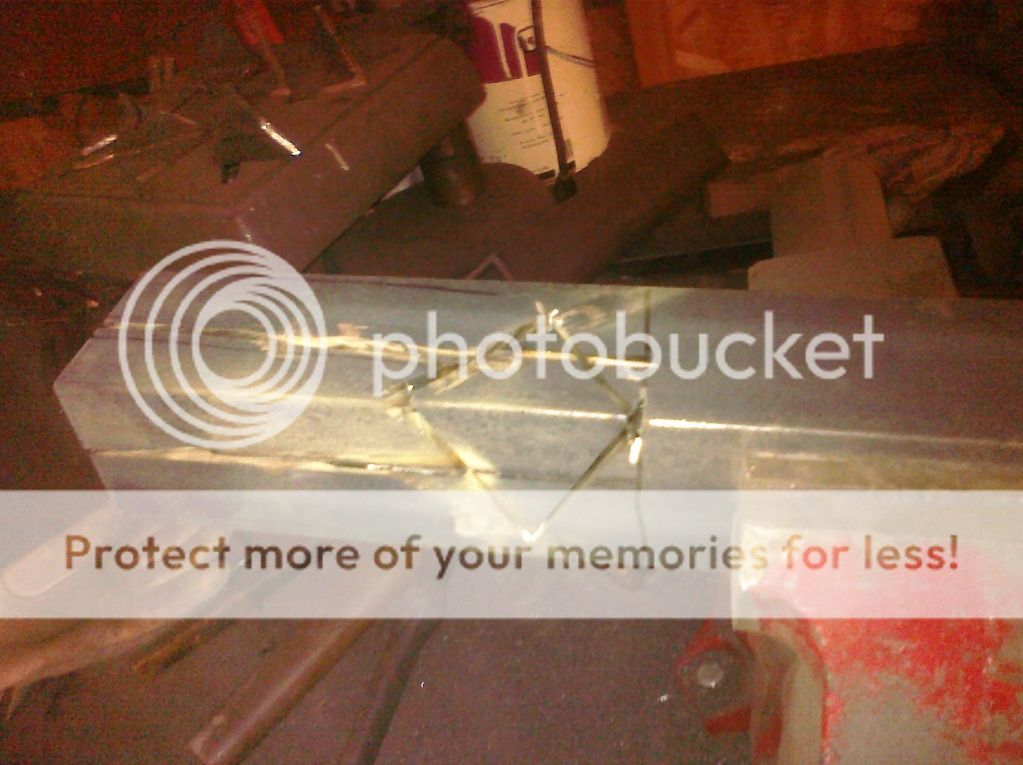

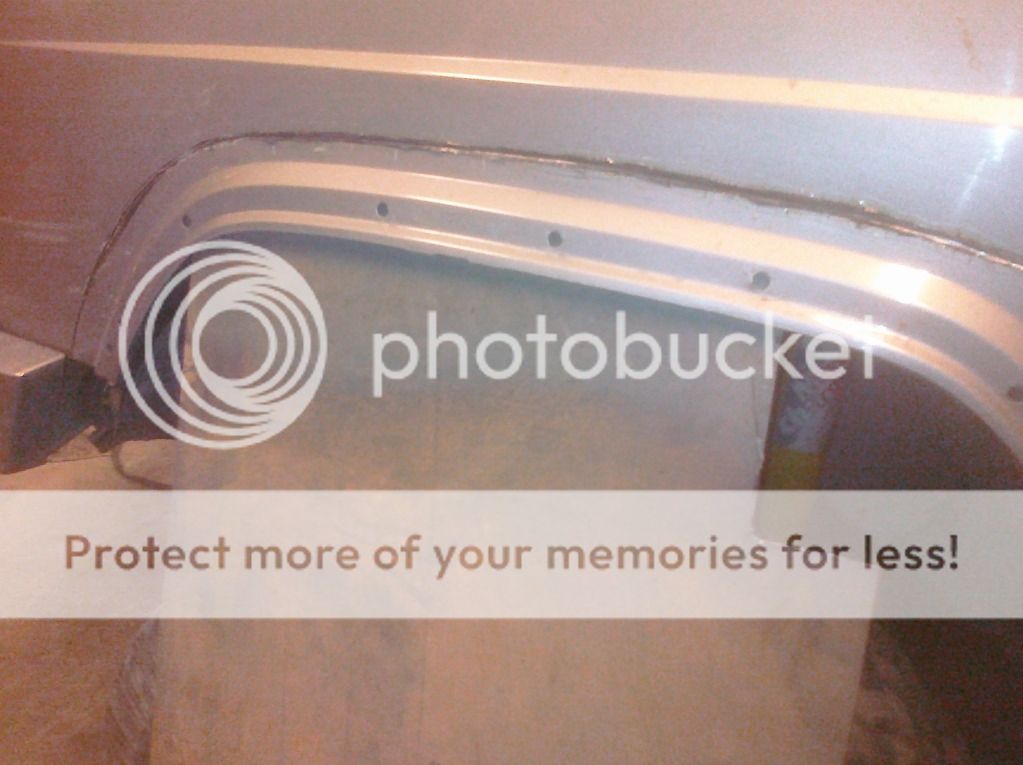

Here is the Size Difference Between The hollow Stock Steering Vs The Solid Alloy Steel Currie Setup.

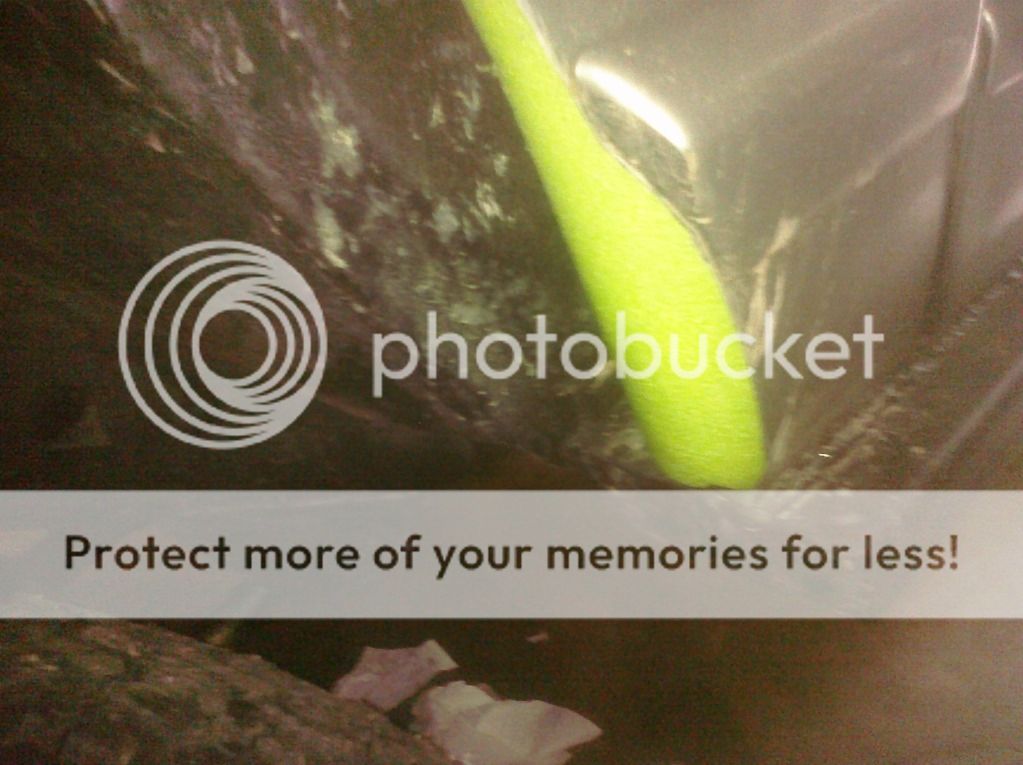

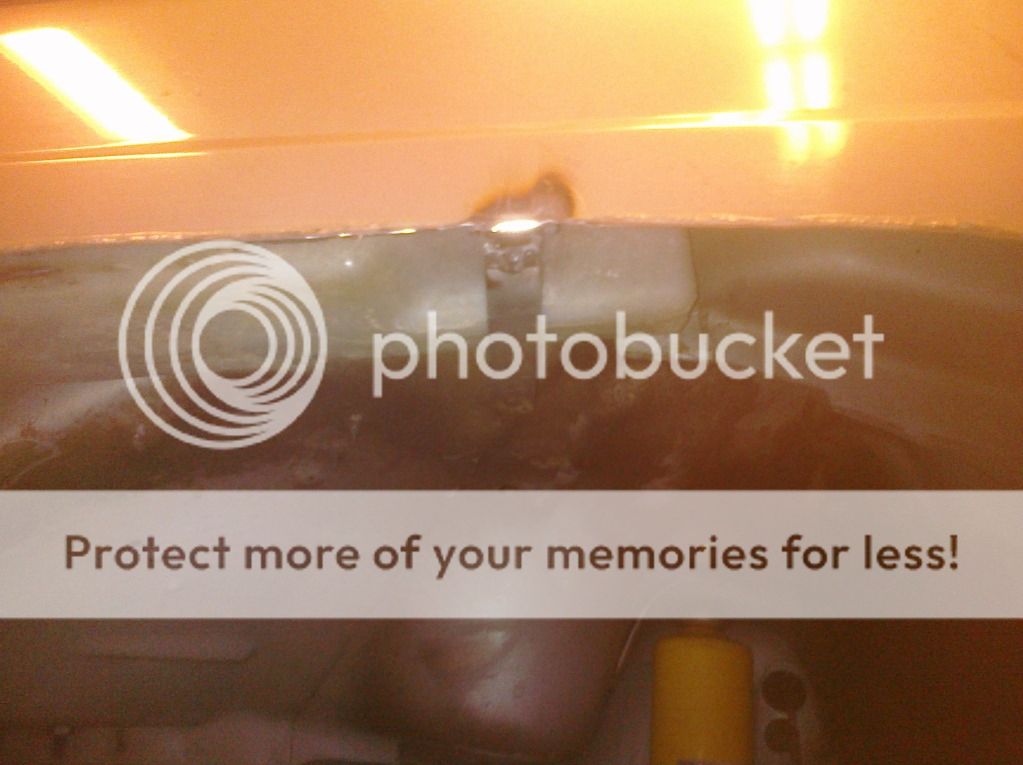

And Here it is installed

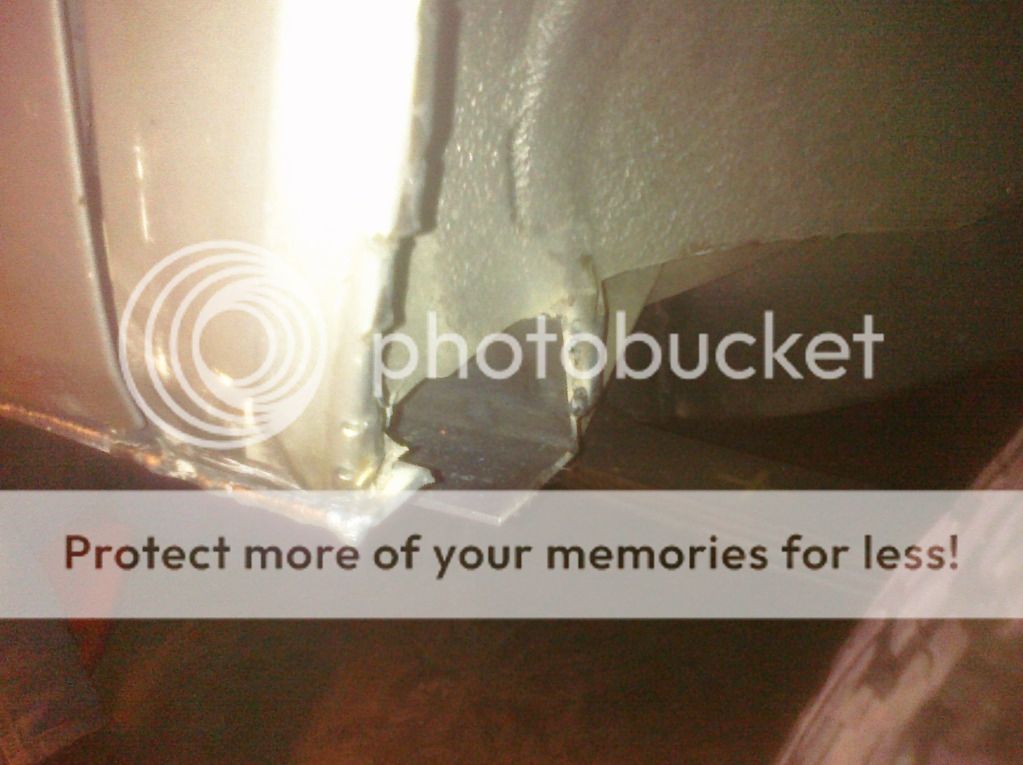

Now I Need to repair my front Skid and remount it For WINTERFEST !!

and follow a writeup of the Cut and Fold Method For the rear .

and follow a writeup of the Cut and Fold Method For the rear .