So Then I started leaking Trans fluid from the stupid quick disconnect at the lower radiator fitting.

So i figured why not do a trans cooler while im at it, And after searching a while i found Talyn's walkthrough of converting to AN fittings and a pushlock type hose and installing his trans cooler.

http://www.naxja.org/forum/showthread.php?t=1026658

And Grimm Jeepers of changing the quick disconnect out on the Transmission end .

http://www.naxja.org/forum/showthread.php?t=1045807&page=3

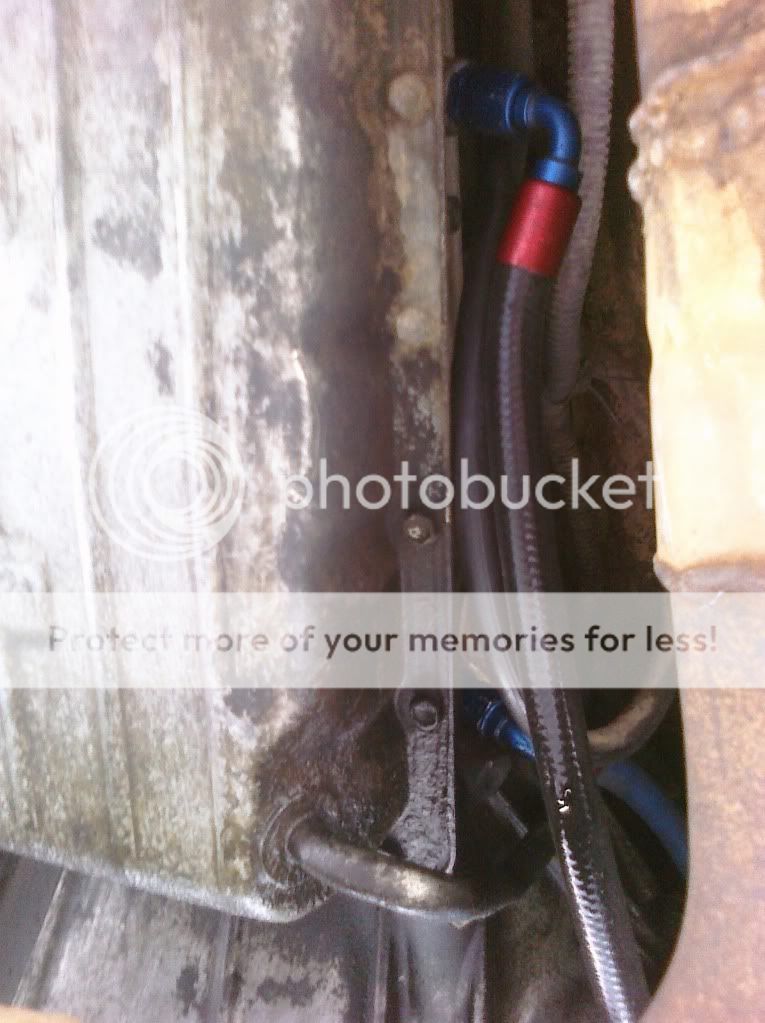

I Replaced ALL fittings and hose with 6AN fittings and Jegs Pushlock hose

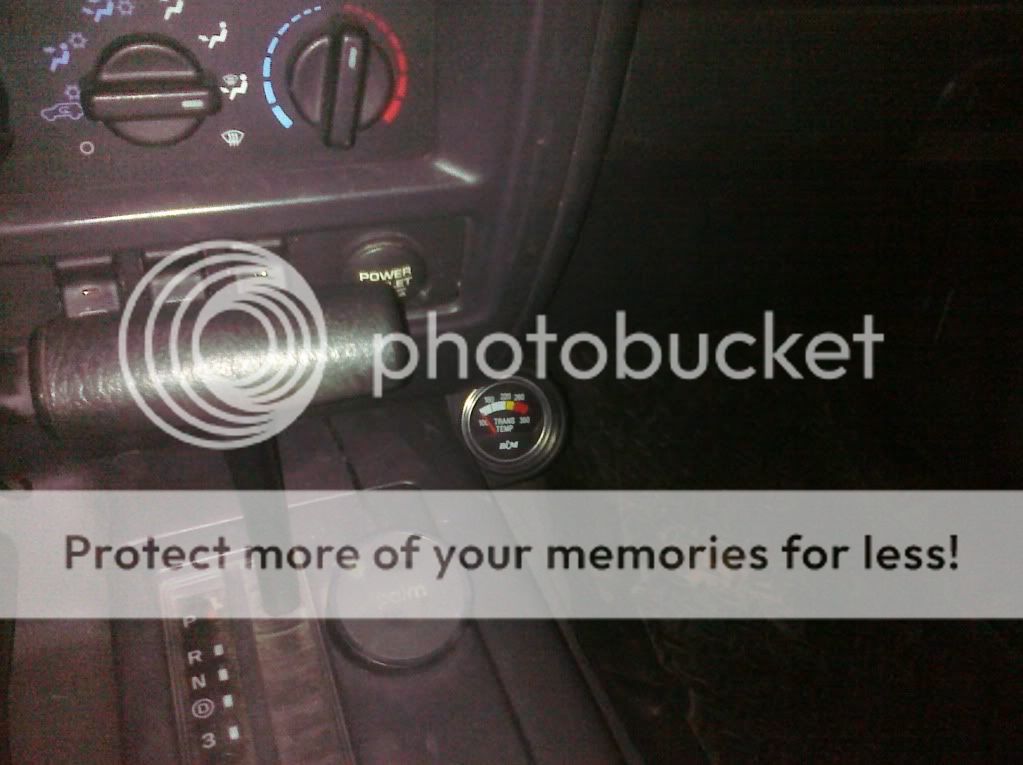

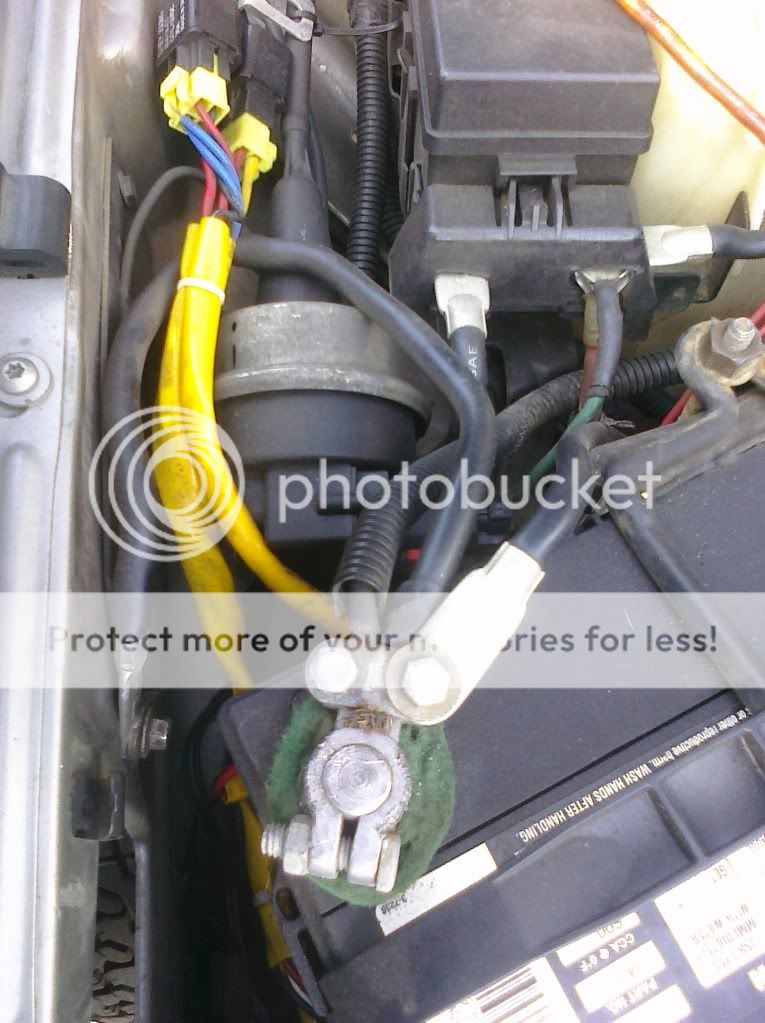

Mine is plumbed from trans to temp sending unit

(with added ground to body of sender)

then plumbed to a filter adapter with a wix 51515

(to gain volume and a real filter).

then through my after market cooler

(in front of ac condensor and fan pass side)

then through radiator heat exchanger and back to Trans..

In winter it runs at about 100

in summer about 150 under normal operation.

if im towing or wheeling it goes up to around 160.

I didnt expect it but my motor runs a noticeable notch under the 210 it allways did .

when i am working the rig and it goes up to 160degrees in the trans fluid my motor will go up to its old 210 and stay there

I never really had it puke from overheating or anything i just figured if it could give me longer life for my trans then why not

searching)

searching)