dcxj1990

NAXJA Forum User

- Location

- Toccoa, Georgia

wanna sale some?? I am pretty sure you would have some sale on here

wanna sale some?? I am pretty sure you would have some sale on here

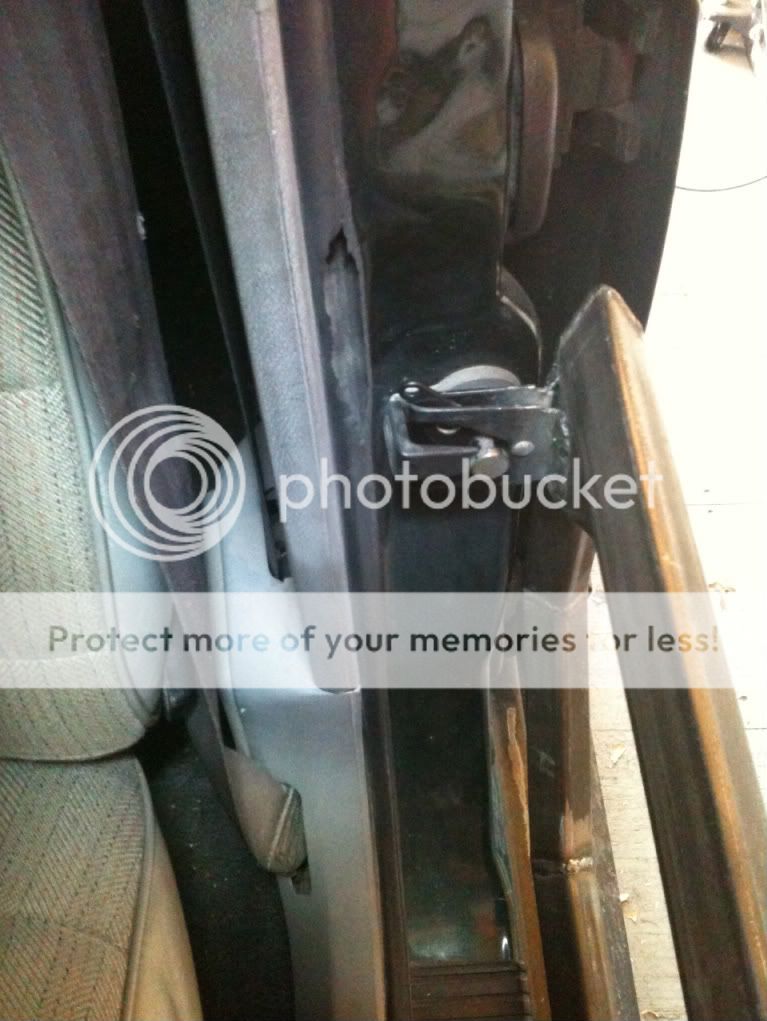

I really like that design, The latches could use a little prettying up lol.

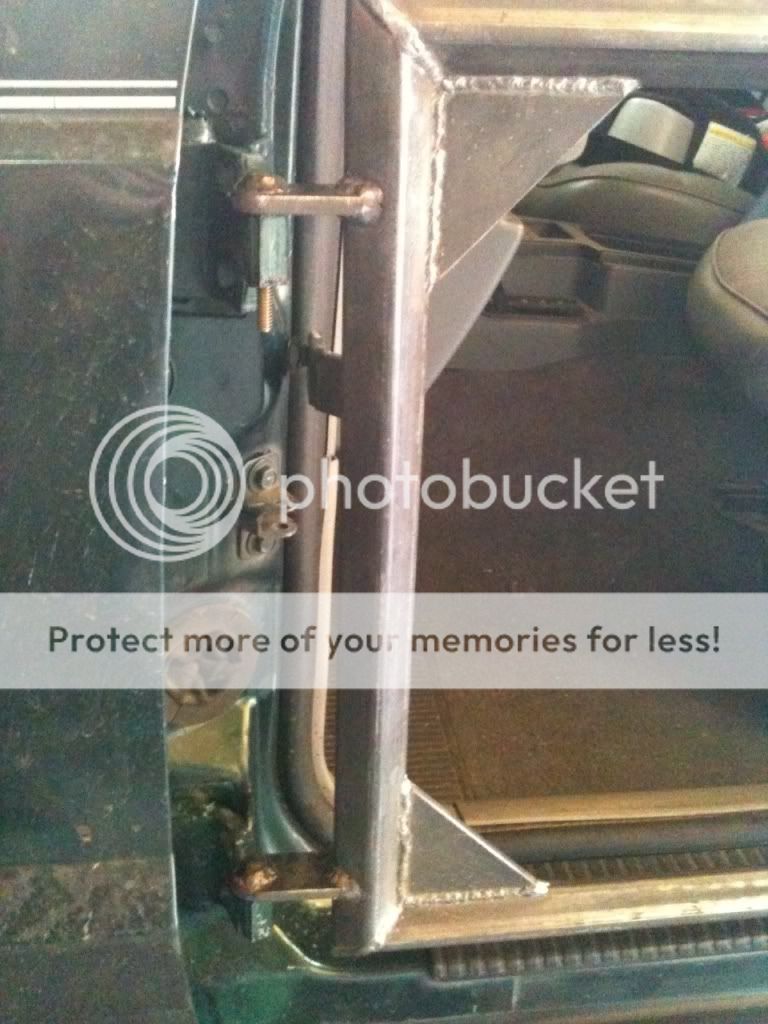

Time for you to start Fabing and selling Skinned and Open versions.

As far as Alligning them to each XJ ..... Harbor Frieght sells sledge hammers pretty cheap.

4 1/2" angle grinder with a cutoff wheel. I wish I had a metal cutting bandsaw, but the angle grinder works well enough.What did you use to notch the tubing? The weld joints look good.

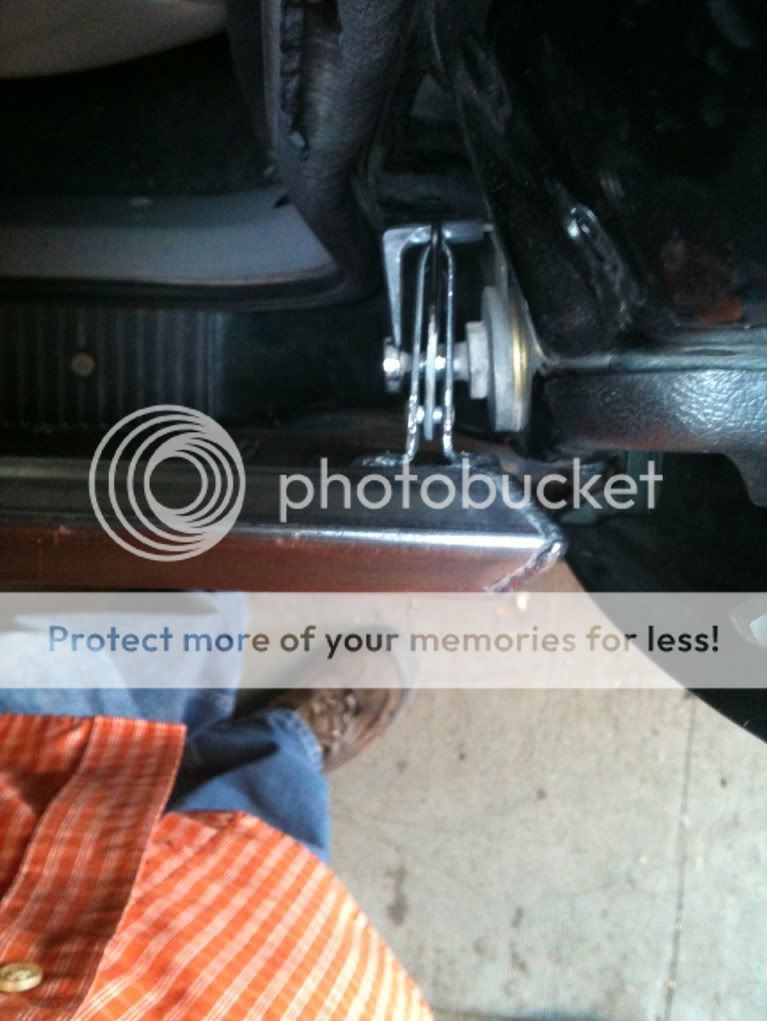

It's not that big of a deal if you can move the hinge points, but the way I make them, there is no movement and the pins have to be perfectly aligned to allow them to slide in and out easily.

I'm not saying I wouldn't make them, just would hate to make them and then people have fitment issues.