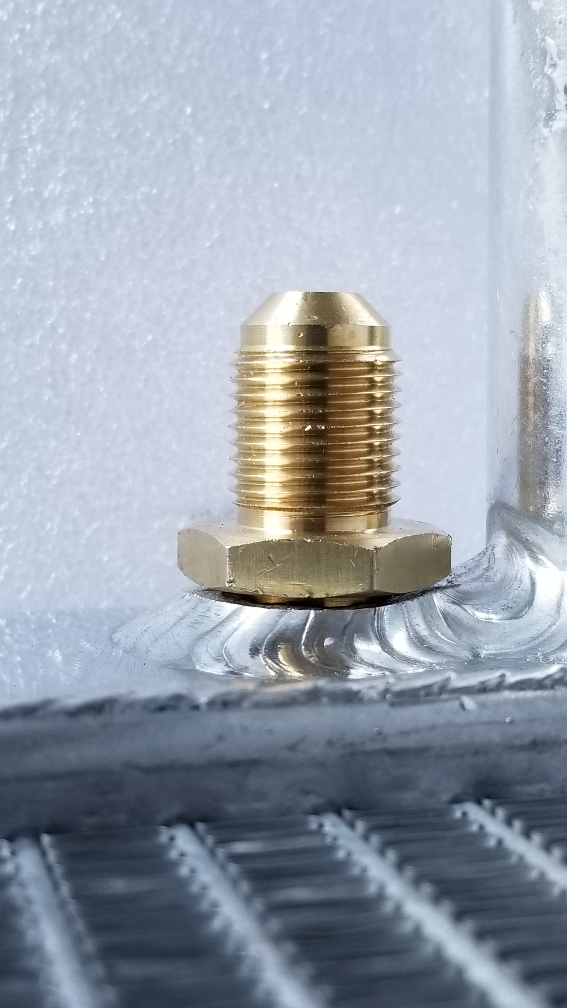

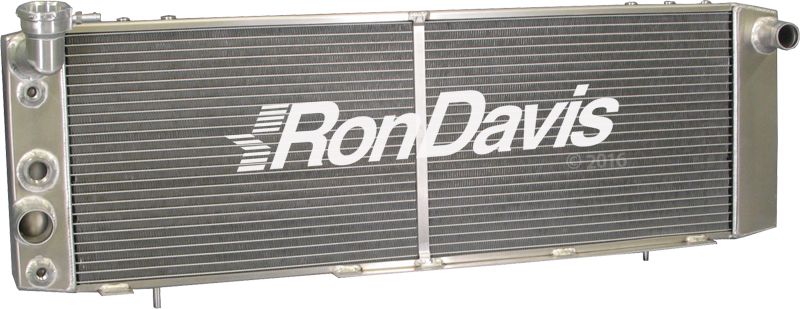

Jim, thanks for posting those very interesting links. After my initial enthusiasm, I looked more closely at their core photo. I agree, its clearly an image of a core used for air-to-air or possibly high pressure oil flow in and oil cooler. Further, the tube spacing and thicknesses are not consistent with their photos of the radiator. The radiator pictures show 28 tubes over 10.82 inches, consistent with 3/8" tube spacing. This would suggest tube thickness of around 0.65 mm, so its possible that the actual tube spacing is even less. I only know of 3/8 or 5/16" spacing in aluminum cores. If this is a high efficiency core with 5/16" center to center spacing, this would suggest 2.0 mm which tubes.

So at this point we are left with a single row radiator with a rather thick core. The stated thickness is 2.5", but their dimension photo shows that this is the thickness of the end tank. Core could be 2 inches which still suggests a very wide tube in the structure. I'm going to try for more information from the seller!

But I completely agree, if the core is as per the image, it would be a real clogger!