Bronzewyrm

NAXJA Forum User

- Location

- Independence,or

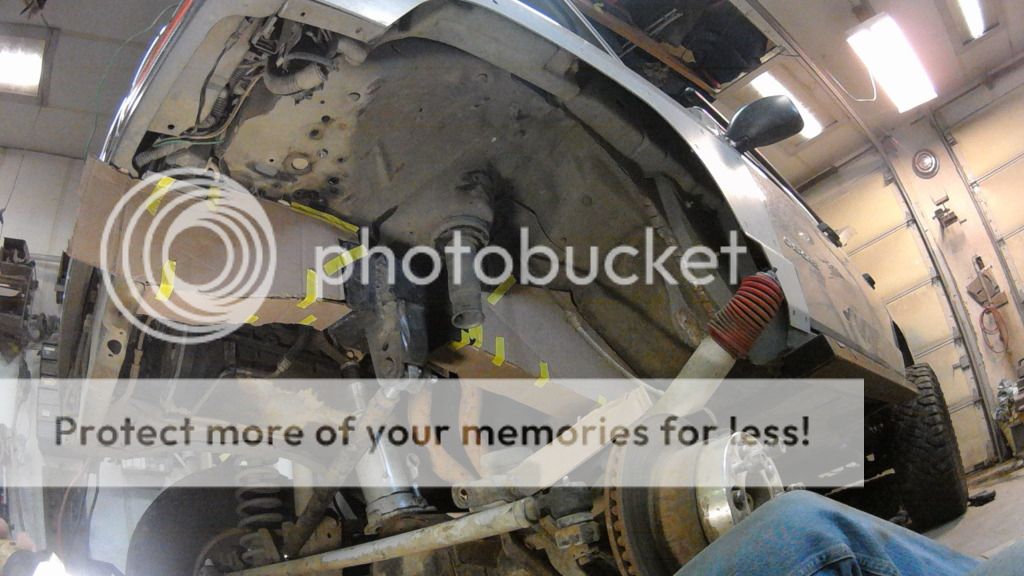

So I ran the t-case dry, and it :explosion

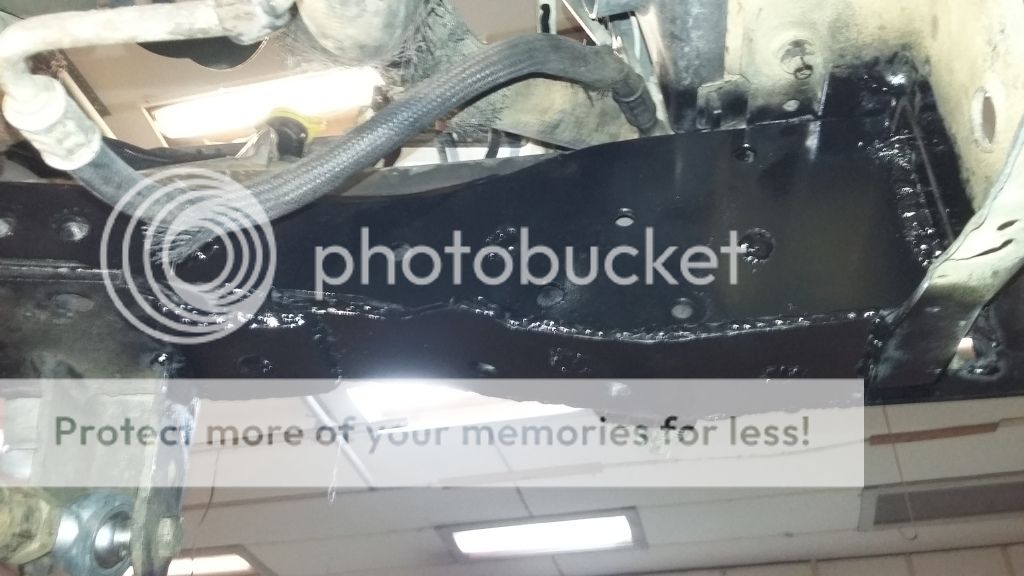

It wore all the plastics inside it down, marrd up the range and mode forks, the chain had stretched to the point of narring up the case and taking out the oil pump pickup. Yeah, it was bad. Luckily SpecFab had one! LairBear had been on his recent extended stay at casa Skinner and I was able to convince him to drag it home with him. Swap some bearings and stuff around put my SYE on it, resealed, and had it in.

Here we go again :repair:

its out!

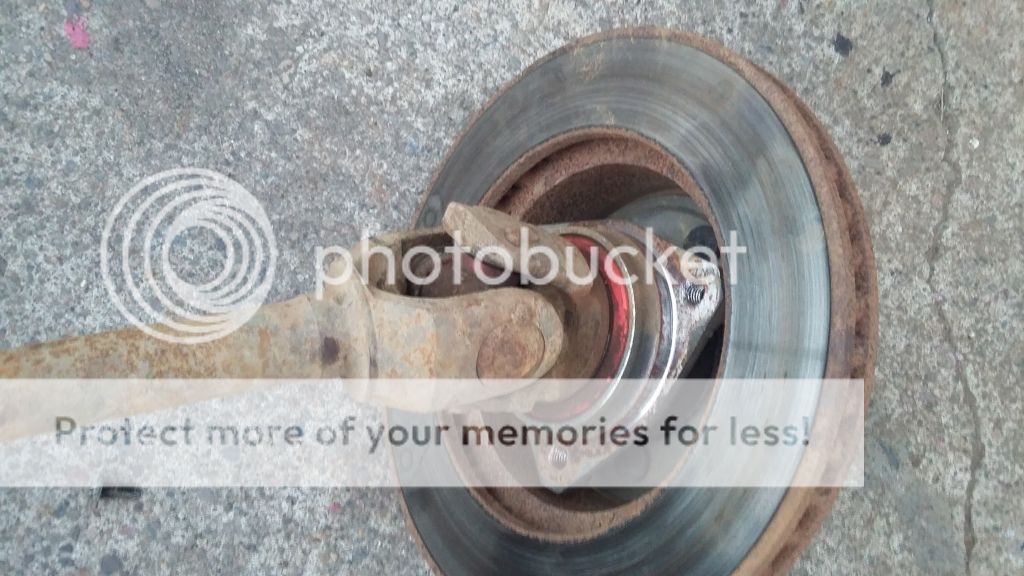

you will see in the following pictures how well the NP231j runs with no fluid. Not...

some of the damage was chain stretch...

It wore all the plastics inside it down, marrd up the range and mode forks, the chain had stretched to the point of narring up the case and taking out the oil pump pickup. Yeah, it was bad. Luckily SpecFab had one! LairBear had been on his recent extended stay at casa Skinner and I was able to convince him to drag it home with him. Swap some bearings and stuff around put my SYE on it, resealed, and had it in.

Here we go again :repair:

its out!

you will see in the following pictures how well the NP231j runs with no fluid. Not...

some of the damage was chain stretch...