16vvincent

NAXJA Forum User

- Location

- Sacramento California

man you did an awesome job in the back!! i love it. wish i had the tools and time to make something like that. looks killer. and i like the air defector too, very neat idea

Thanks cencal. I appreciated the compliments.

And I did a considerable amount of work on the rear bumper this past week and managed to get most of it burnt in on the weekend.

As per usual, first thing to do is get the old bumper off:

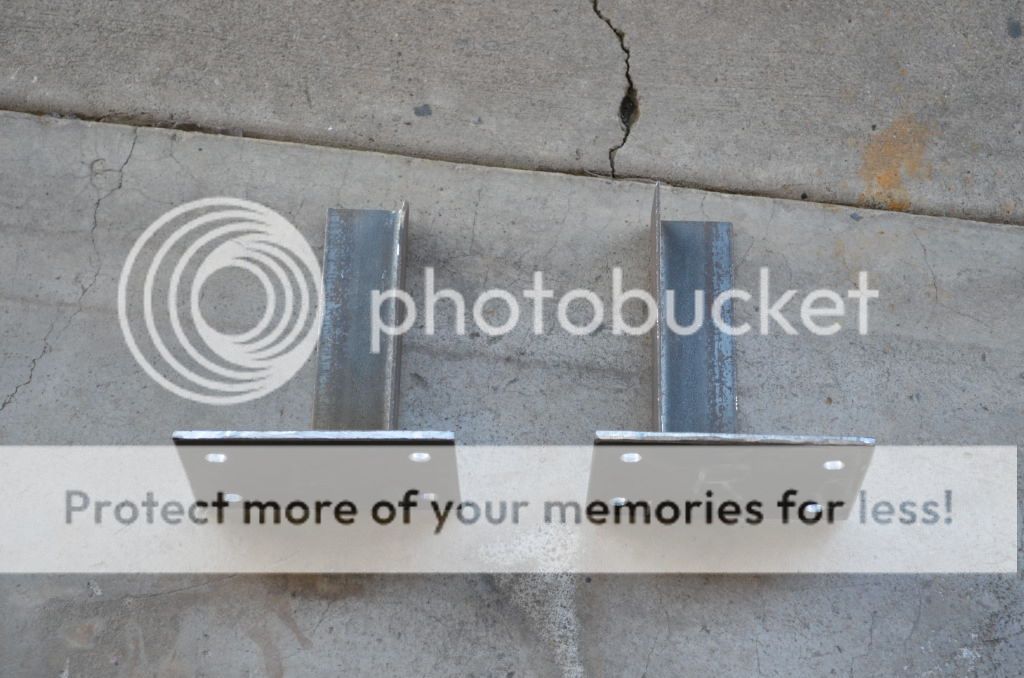

Make some mounting plates out of 1/4" plate:

And mock the bumper bar into location for measurements:

The bar is 2x4x.25" rec tubing, cut 65" long and with a slight angle cut at each end to match the rear 1/4 shape.

Also, to improve the towing strength and help support the overall weight of the bumper, I added a couple of lengths of 2x2x.25" angle iron to the inside area of the bumper mounting plates. These will have nuts welded onto them for bolting through from underneath.

And because of the angle iron, the openings had to be enlarged:

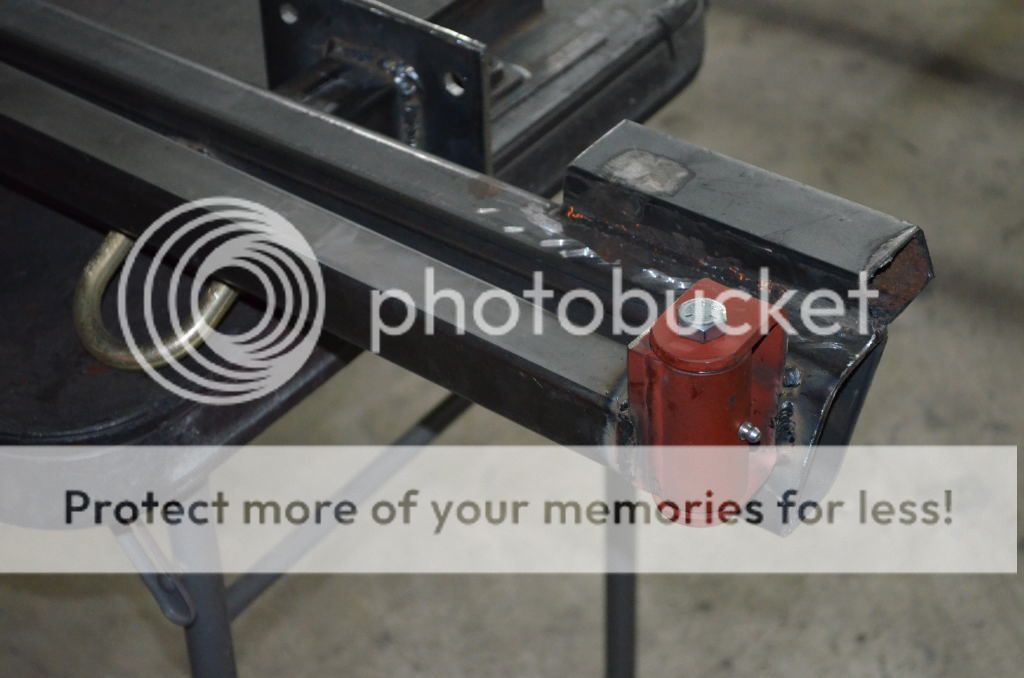

After bolting the mounting plates into place, the bumper was re-mocked into place and stand off measurements were taken, after the bumper bar was sitting where I wanted and where is looked the best.

For the standoffs, I used 2x3x.25 rec tubing cut to 3" long.

More photos later.