jeepinwi

NAXJA Forum User

- Location

- Eau Claire, WI

XJoshua-

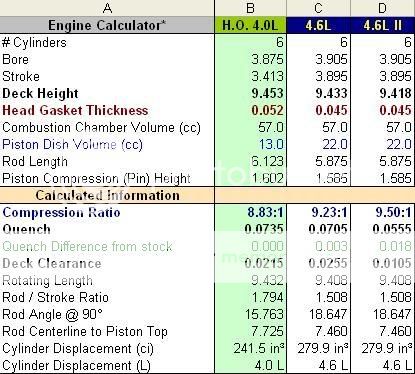

What's the reason for milling .035" from the block? Why not mill only .020" from the block to keep the quench close to stock? Your CR would drop a little, but you won't lose much power. Your 88 block is identical to any other 4.0 block, regardless of year. You're effectively building an HO since you're using the 7120 head.

For the bolts, If I remember right, it is a standard SAE bolt that attaches at the top of the block. Either a 5/16" or 3/8"...that's just a guess. for the bottom, just take a couple longer bolts that will fit through the holes and attach on the other side with a nut. When I got my complete 4.2L engine for parts, I disassembled it in the back of my YJ because I didn't even have an engine stand at the time!:dunno:

What's the reason for milling .035" from the block? Why not mill only .020" from the block to keep the quench close to stock? Your CR would drop a little, but you won't lose much power. Your 88 block is identical to any other 4.0 block, regardless of year. You're effectively building an HO since you're using the 7120 head.

For the bolts, If I remember right, it is a standard SAE bolt that attaches at the top of the block. Either a 5/16" or 3/8"...that's just a guess. for the bottom, just take a couple longer bolts that will fit through the holes and attach on the other side with a nut. When I got my complete 4.2L engine for parts, I disassembled it in the back of my YJ because I didn't even have an engine stand at the time!:dunno:

Last edited: