#Racecars.

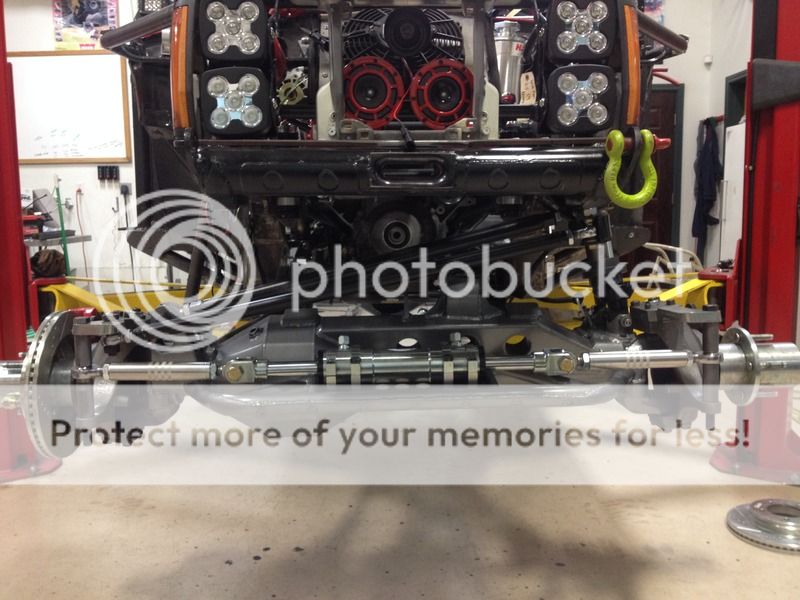

Steering has been an on going project for several months. We called up Jeff Howe, and picked his brain on the ideal setup for the 4500 class. For the pump, Jeff recommended using a Trophy Truck series pump. A power steering system ultimately comes down to flow, and these pumps deliver. We got the pump from Jeff, but quickly found out Howe's bracket wasn't going to for us (this isn't a trophy truck). We reached out to Drew at Goatbilt, and got Drew on board with prototyping a LS based bracket for this pump. By the end of summer we had our monster pump mocked up. Drew also hooked us up with one of his alternator relocation brackets as well, which mounts our alternator up top on the passenger side out of harms way.

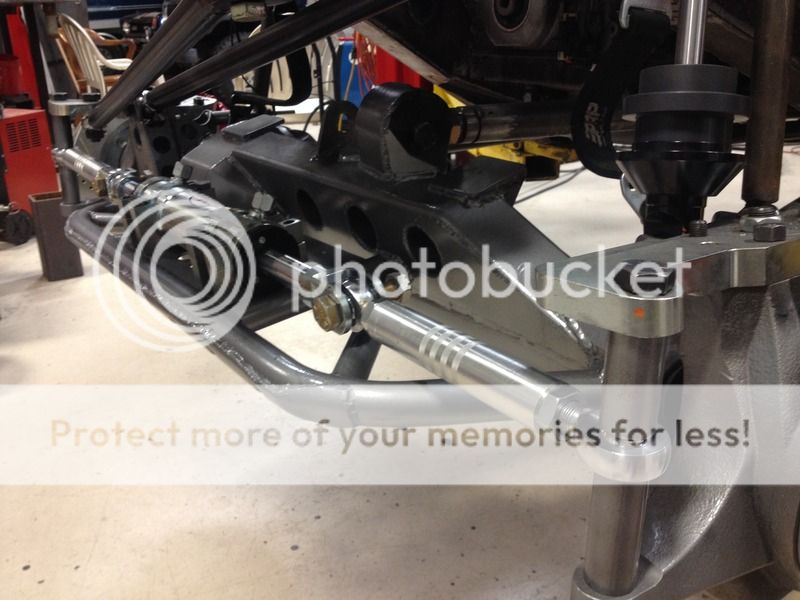

In combination with the Howe's Trophy Truck pump, we're running a 2.5" double ended ram for assist duties out front. We still have our Howe modified Scout steering box to stay class legal, which is connected via mechanical linkage through the drag link.

We built a ram mount on our front axle, doubled up the wall thickness on the outer edge, and added some sweet 7075 aluminum tie-rods to the setup. We tried not to cut corners on the steering as it's a critical system that can end your day quick if it's not up to par.

After getting our steering pretty much completed Winton and I put in a late night at the shop trying to tie up some loose ends to get the car ready to go in for plumbing. Oil Filter Service in Portland offered to let us bring in the car to plumb the brakes, trans, radiator, and steering. Much easier than making 37 trips back and forth for fittings. They saved us a ton of time, and really helped us out with the plumbing on this project!

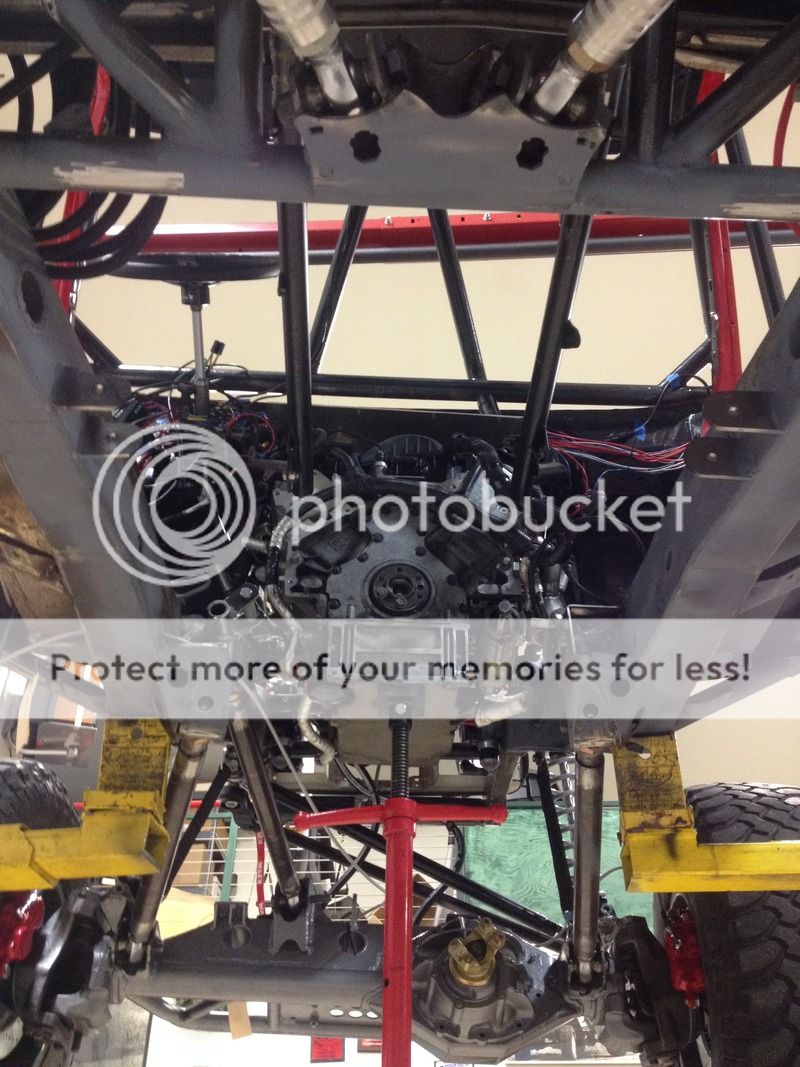

Back from plumbing we tore back into it on the lift.

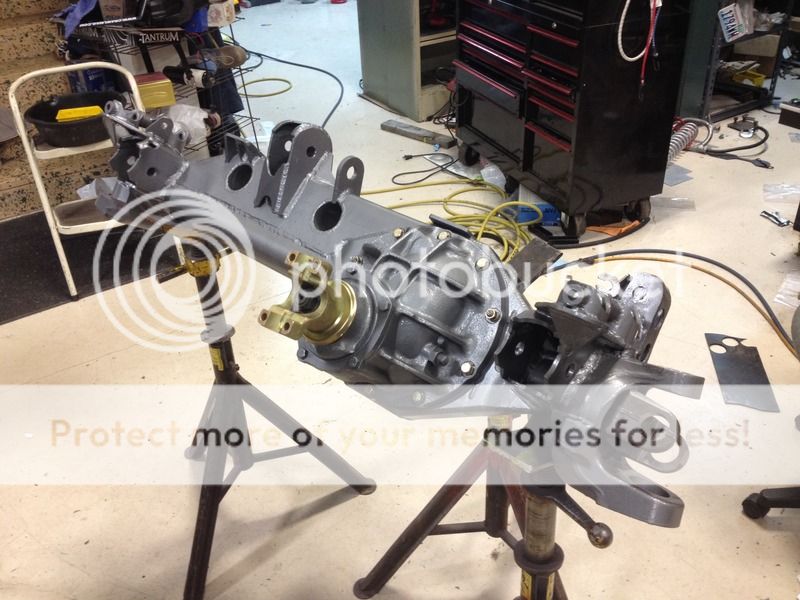

Out with our mock up transmission, and prepping for final install of our ready to run transmission packed with some billet goodies and a custom A1 torque converter.

Here you can see our mid-plate mounts in, transmission in, drive line on with pillow block mounted, exhaust in, and a whole lot of painting got done. Suddenly all that space we started with was now non existent. However, the extra time we spent to make this thing easy to service sure paid off.

One of the few remaining fab projects was our boat side armor. We chose to use .125" Hardox hardened steel plating. We've been running similar stuff on our #689 Ultra4 car with great results. This stuff is not fun to drill or cut, but we managed to get both our boat sides bolted on. We could have welded them in solid, but we liked the having option of not running them for races such as Vegas to Reno where they just aren't needed and tend to pack full of silt.

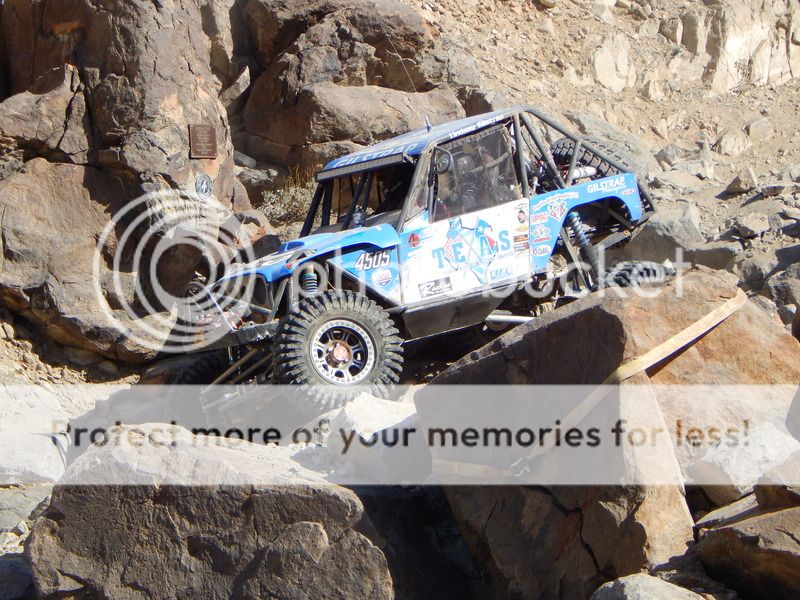

It was around this time when left MJ behind, and headed down to KOH. While it was disappointing not having the MJ there, KOH is a total blast regardless. Here's a few pictures from the trip...

Lindsay Gilstrap in the 4500 class dropping down Jack Hammer.

Larry Nickel 4500 class at the top of Jack.

Note to self, keep it rubber side down.

Absolutely beautiful down there.

Sledge Hammer is no joke.

Schererererer takes 2nd overall in the main race.

Read more about my trip

HERE.