Were mainly discussing the bolt used. Anak's bolt addresses issues of compressing plastic that deteriorates over time.

I'm going to try bending the hd industrial lugs I have ... appear to be almost twice a thick as the copper lugs.

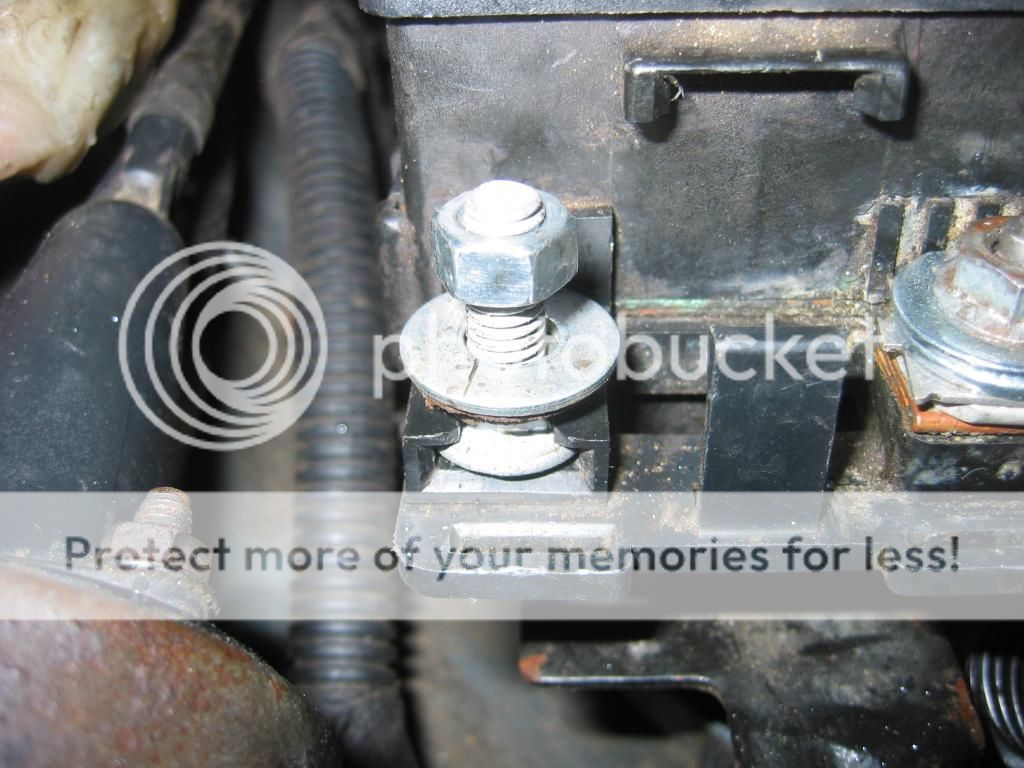

Here's a pic of a bolt, appears use a flanged hex head with the bolt welded on the top of the head.

I'm going to try bending the hd industrial lugs I have ... appear to be almost twice a thick as the copper lugs.

Here's a pic of a bolt, appears use a flanged hex head with the bolt welded on the top of the head.

Last edited: