clydefrog

NAXJA Forum User

- Location

- Northern California

Awesome, thanks man. I was going to fab up a fiberglass one, but the one you have looks perfect.

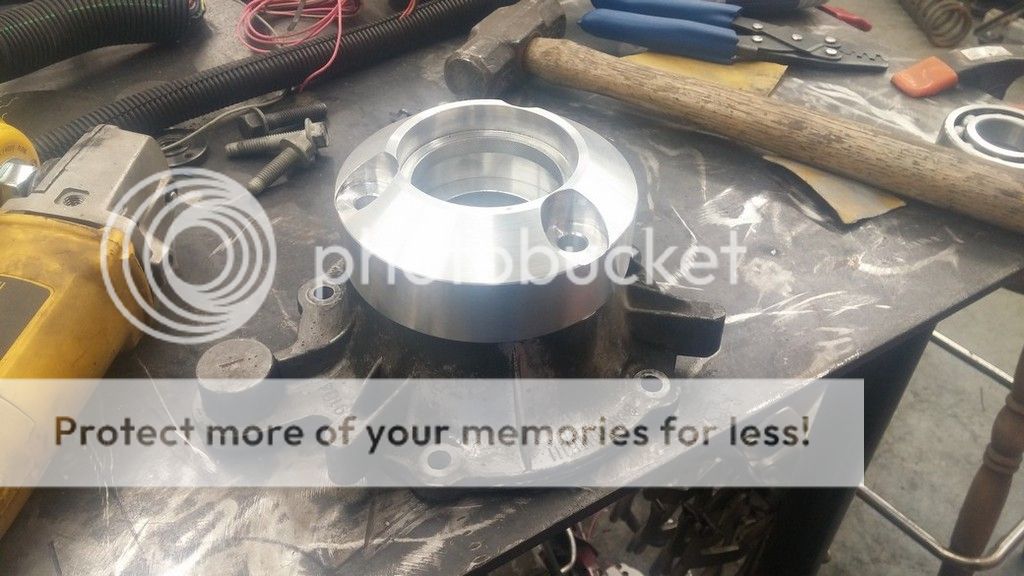

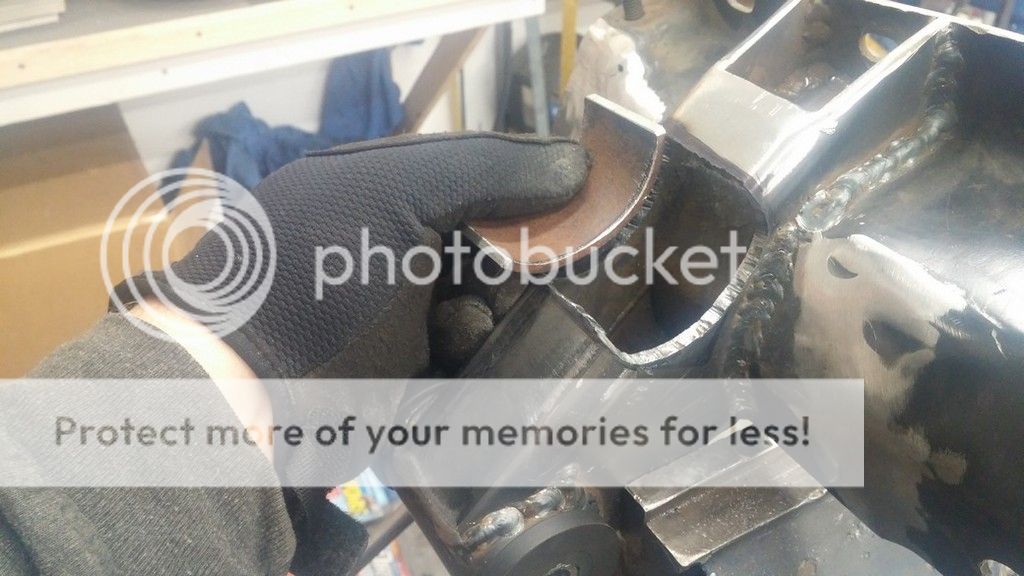

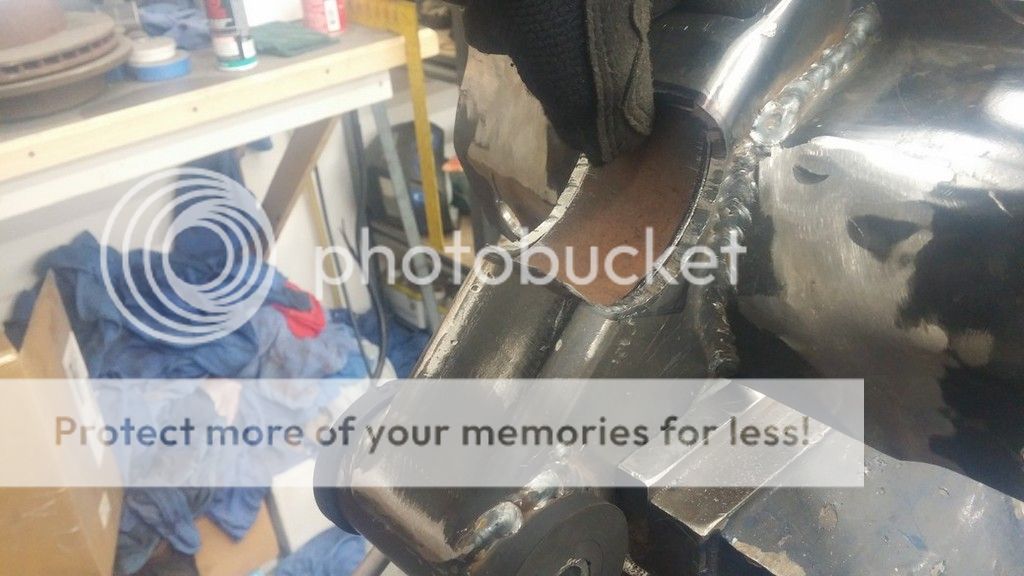

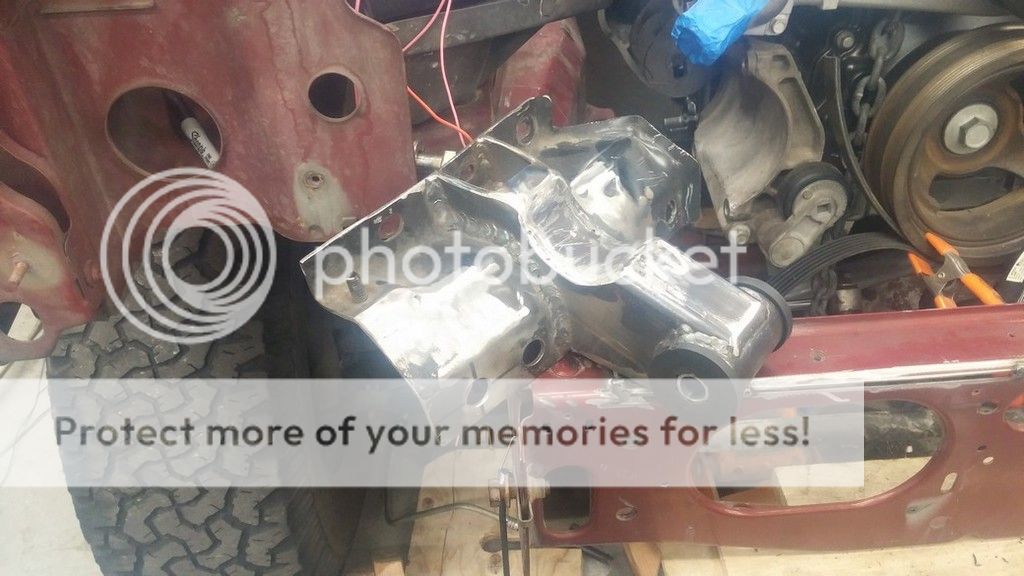

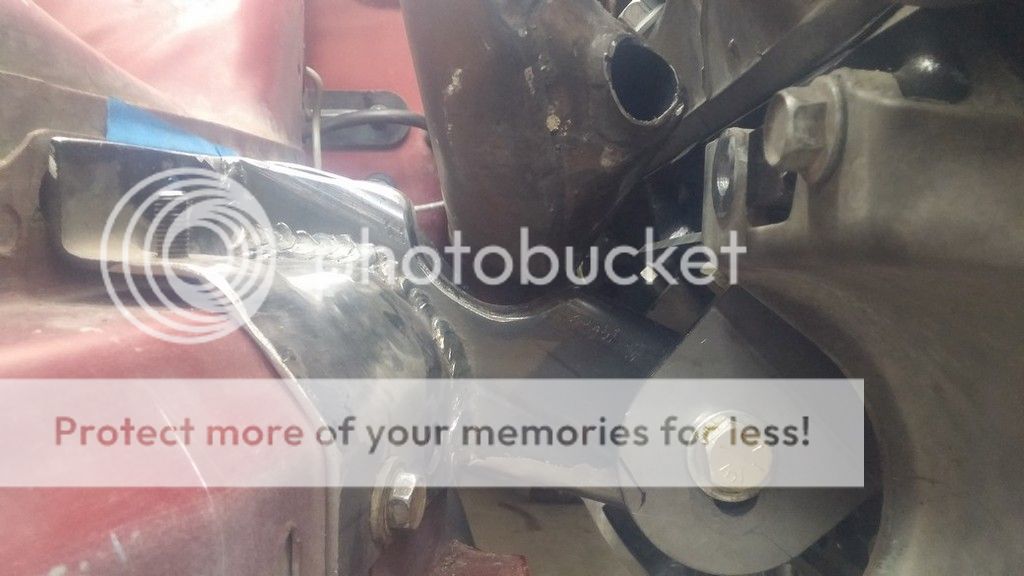

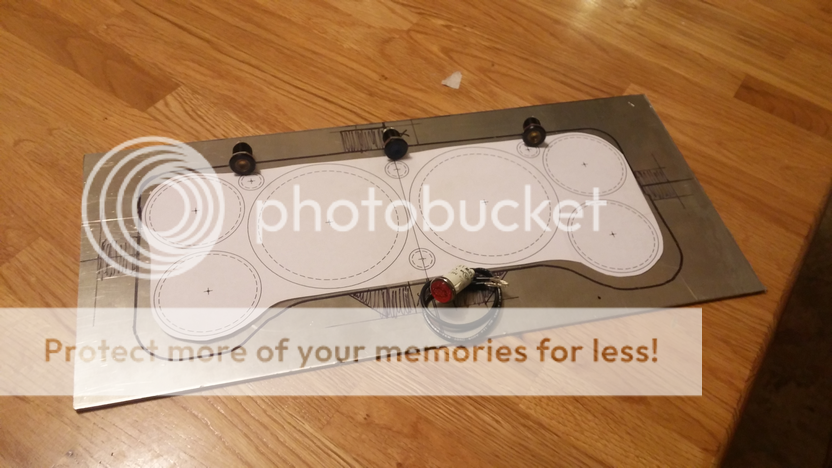

Looking good. I made my own motor mounts too, it's nice to put the motor where you want it instead of where Novak thinks it should be.

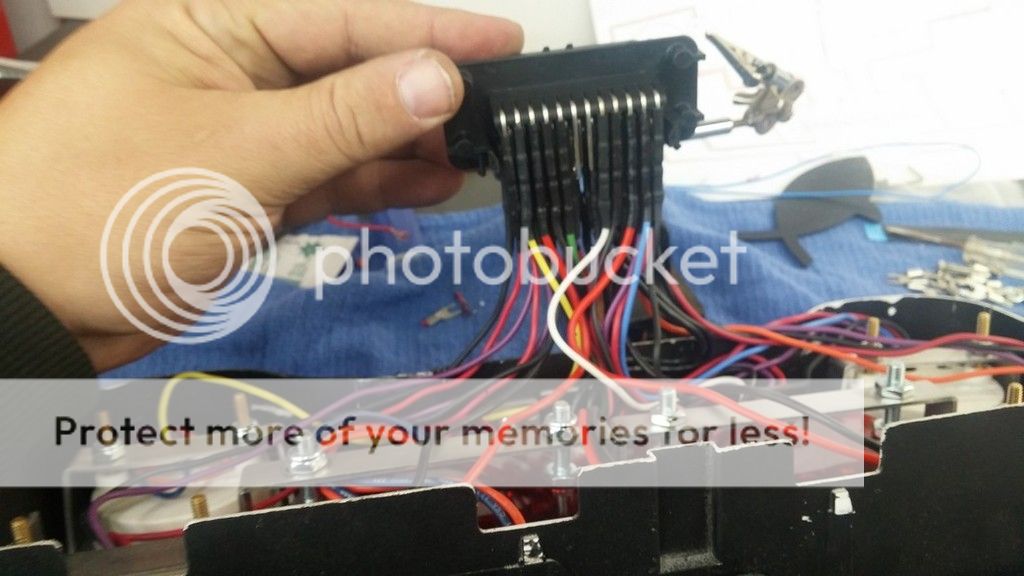

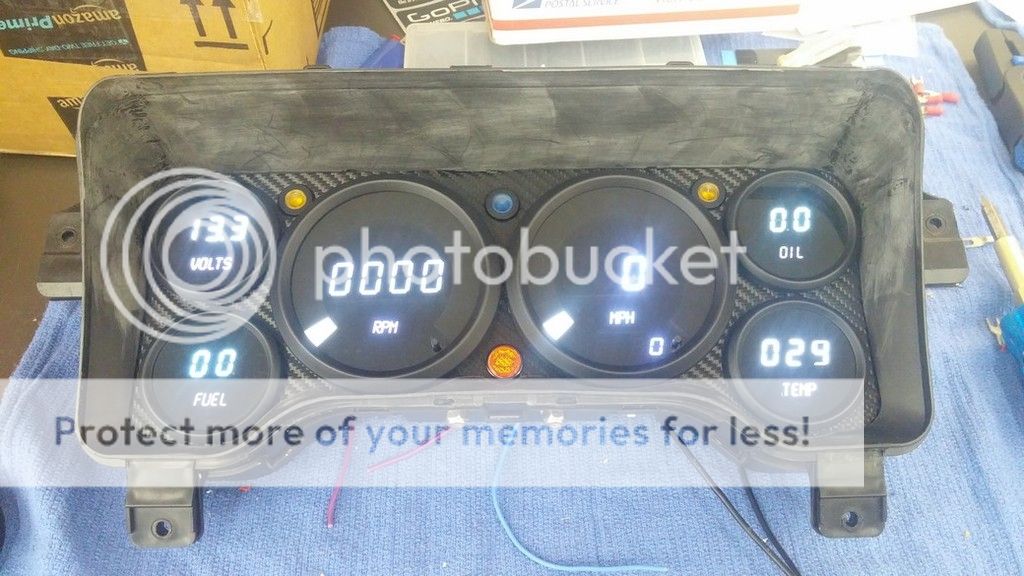

Even though I'm not a fan of digital gauges, this does look nice. And what you did here with the connector is awesome, about a million times better than the back of mine.

Holy shit that looks amazing! Really love the look of those gauges. I should have you do mine!

thats pretty nifty, kudos.

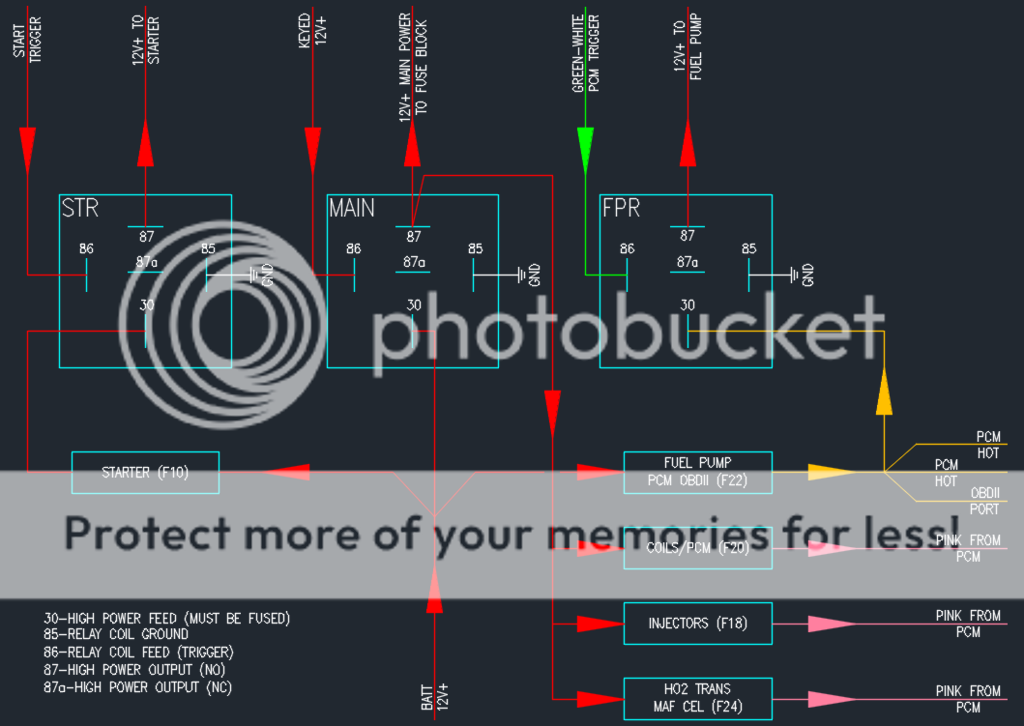

Pin 9 Green says it's a control signal. Put it on the ground side of your relay and it should work.

Fuel Pump Relay Control - The computer on GM fuel injection systems is designed to control a fuel pump relay. The computer does this by supply a 12v+ (POSITIVE) signal to the relay. The signal is only present for two seconds at key on. Fuel pump operation resumes when cranking over. The PCM ONLY commands it back on when the PCM reads that the engine is turning over. So, if there is a condition where there is a bad crank sensor, fuel pump will come on, turn off, and will not turn on when cranking.

Thanks for the reply John... However according to everything I am reading pin 9 should supply +12v for a couple seconds at key on and then when it senses the crank signal turns it back on for starting. This is from LT1swap.com:

I tested it both ways - as a ground and as a hot and I get nothing either way. I sent Brendan at LT1swap an email but he takes a long time to reply these days. Last email I sent him took 10 days to get a response...

I posted a question on ls1tech.com too but no replies there yet.

If you're a member of Pirate check out the 5.3 swap thread in the Hardcore Jeep section. Post it up there and a lot of times Wayne replies who is the guy that does 150tunes.com