9T3XJ

NAXJA Forum User

- Location

- FoCo, Colorado

Griffin has a 3" thick aluminum radiator that a lot of the Jeepspeed guys run, I think it's normally just under $500.

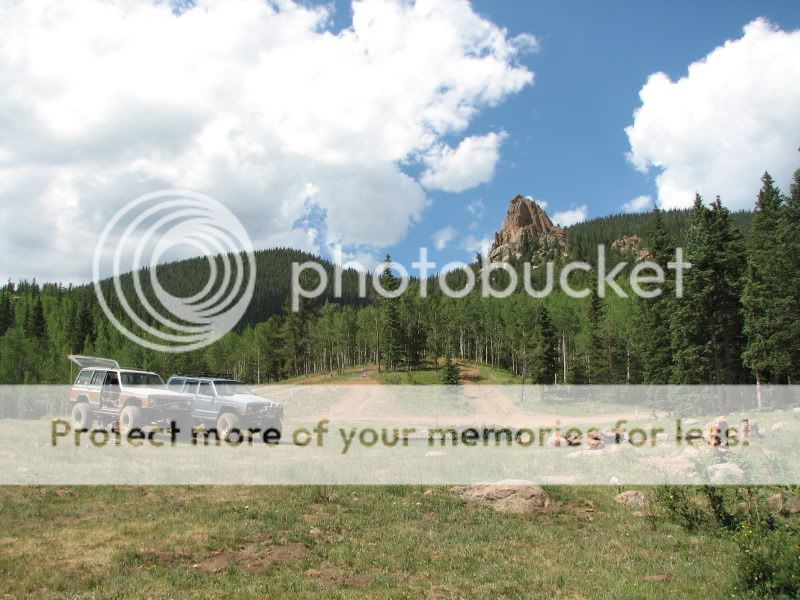

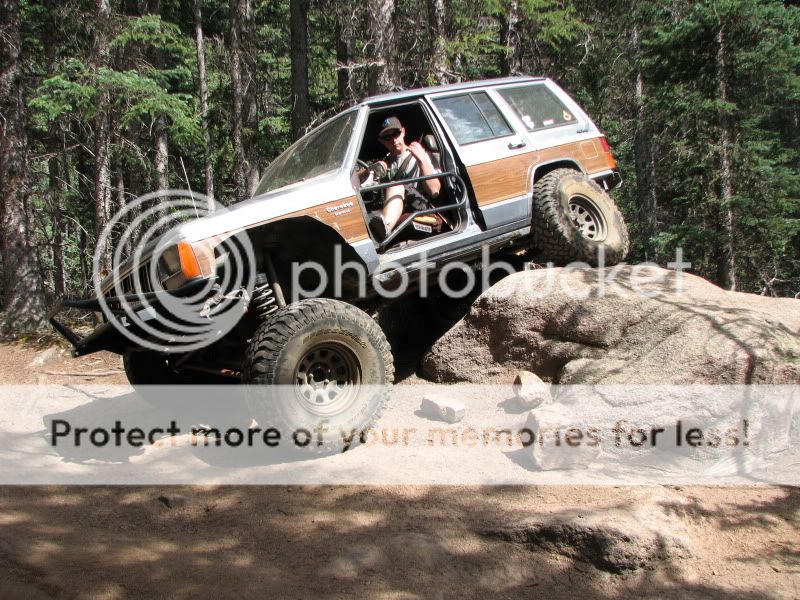

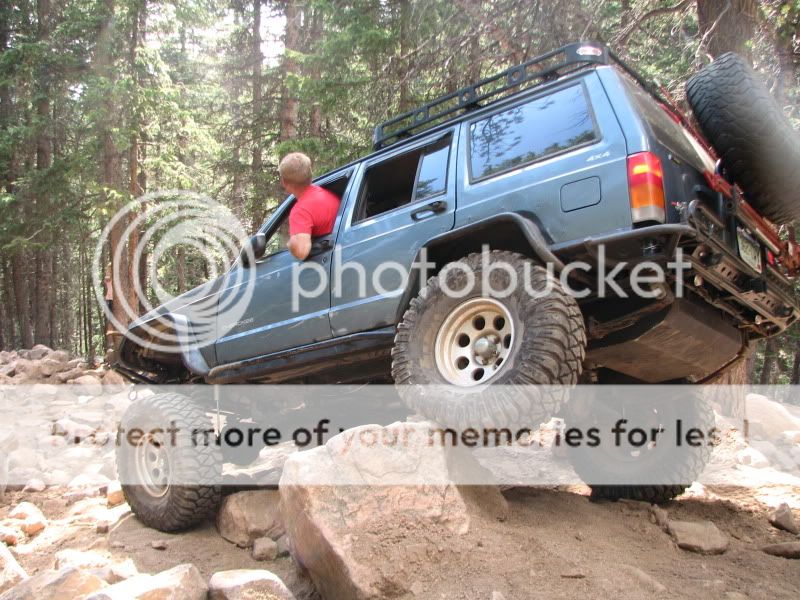

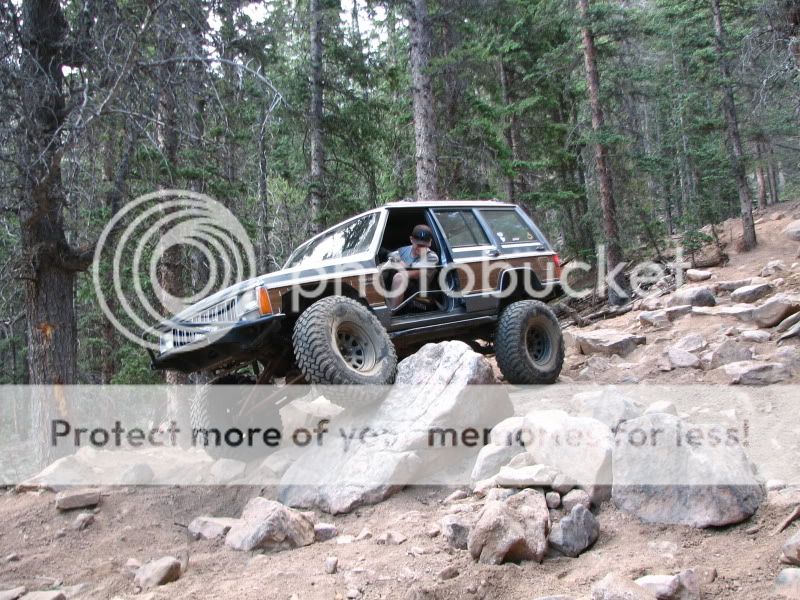

1. Yes!Although I’m driving the rig and hope to get it on a trail this weekend I still have to install a new radiator and get busy installing some A/C, I figured it was time for this:

Since the end of this swap is at hand I thought I’d take up a little bandwidth and share some info in a condensed format to help those of you that are considering this swap. I’ve learned a lot along the way, wasted some money and plenty of time. Hopefully you can avoid the same pitfalls.

#1

Install your new oil pressure sending unit and water temperature sensor BEFORE you drop the motor in.

#2

The only header that will fit the 5.3L in an XJ is the Sanderson header sold by Novak Conversions.

#3

The only motor mount brackets on the market as of 06-07-10 are also from Novak.

#4

Although it s possible to adapt a GM gauge cluster to work in an XJ, the amount of time spent doing the wiring and modifying the dash is huge.

#5

Establishing and maintaining a good relationship with the local parts house will save you a lot of time and money.

#6

With the right adapter ring, you can indeed run a GM fuel pump assembly in your 97+ gas tank.

#7

Wiring in a new motor is not as complex as some believe, but basic understanding of electrical circuits is needed.

#8

A stock AW4 shifter can be modified to control a 4L60E transmission and maintain a stock appearance.

#9

Although the LSx truck intake makes more low end torque, the additional hood mods may not be desireable for some.

#10

Braided fuel lines are the simplest means of connecting the engine to the fuel tank. Yes they cost more but the time savings is immense.

#11

You don’t have to be a master fabricator to do this swap, but some basic skills are required.

#12

You don’t have to re-invent the wheel to do this swap….and you don’t have to do it alone either. Take the time to read about what others have done and use their mistakes and success stories to simplify your project.

The Thank You’s…

Thanks to all of you that have followed this thread and shared your comments and opinions.

Thanks to JohnD (naxja.org) for answering my questions and sharing his knowledge and experience.

Mega-Thanks to Brendan Patten of www.LS1Swap.com for the incredible website and back-channel assistance.

Most of all a huge Thanks to my wife and kids for tolerating my long days and nights in the garage, trips to the junk yard, mindless babbling about headers and wiring.

Frank, would you be willing to go into more detail on what wiring needs to be done on the XJ itself? I want to see what is involved before I commit to the swap. I have limited time between wheeling holidays so I'm trying to figure out how much needs to be done and how much time I need to allot for it. Novak is reluctant to give up the info unless you buy some parts from them. It might just be easier/quicker for me to freshen up my turbo motor if there's too much to deal with. Let me know. Thanks.

It really is all in here http://www.lt1swap.com/wiringharness.htm

I studied for a while then it took me a Saturday to do it.

Thanks John, but I was referring to the wiring that needs to be tied into on the XJ itself.

Not at all, that's what this thread is for.Frank, if you don't mind, Im gonna throw in my .02 worth on the swap do's and don'ts.

Frank, would you be willing to go into more detail on what wiring needs to be done on the XJ itself? I want to see what is involved before I commit to the swap. I have limited time between wheeling holidays so I'm trying to figure out how much needs to be done and how much time I need to allot for it. Novak is reluctant to give up the info unless you buy some parts from them. It might just be easier/quicker for me to freshen up my turbo motor if there's too much to deal with. Let me know. Thanks.