uncc civilengineer

NAXJA Forum User

- Location

- Winston Salem, NC

UBE's are just not safe... everything on a XJ should be bolted on, everyone knows that...

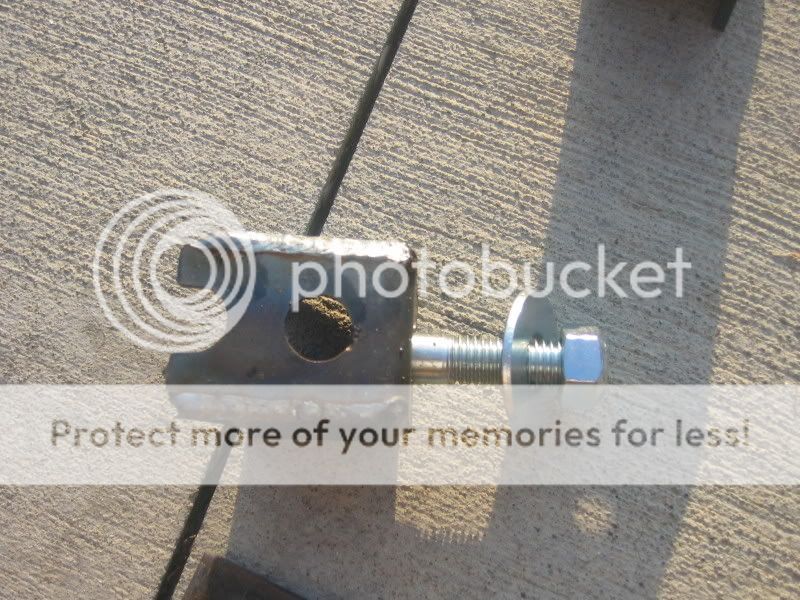

I for one trust (4) 5/8" G8 bolts more than U-bolts...

Also, I didnt read everything so I'm sure I missed this but one good aspect to the UBEs it the ability to set you pinion angle w/o the use of shims. It's also a nice wide, easy 0.5 - 1.5" lift...

The TNT kit also come w/ some nice upper plates that make the addition of bumpstops very easy...

I for one trust (4) 5/8" G8 bolts more than U-bolts...

Also, I didnt read everything so I'm sure I missed this but one good aspect to the UBEs it the ability to set you pinion angle w/o the use of shims. It's also a nice wide, easy 0.5 - 1.5" lift...

The TNT kit also come w/ some nice upper plates that make the addition of bumpstops very easy...