DanMan2k06

NAXJA Forum User

- Location

- Damascus, MD

Because I'm a genius...

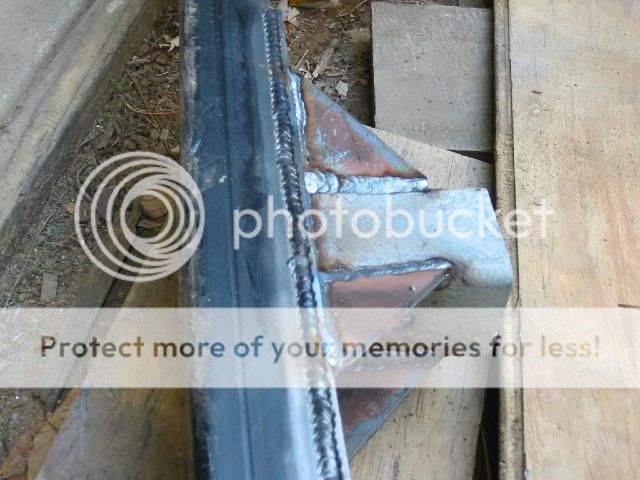

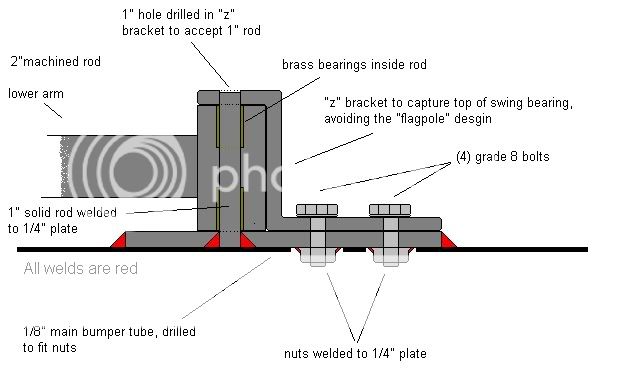

nah j/k, the two front ones can be easily accessed from the end of the tube, and the other two I will drill holes where the tip of the mig will slip in. All they need are some heavy tacks and everything should be copacetic.

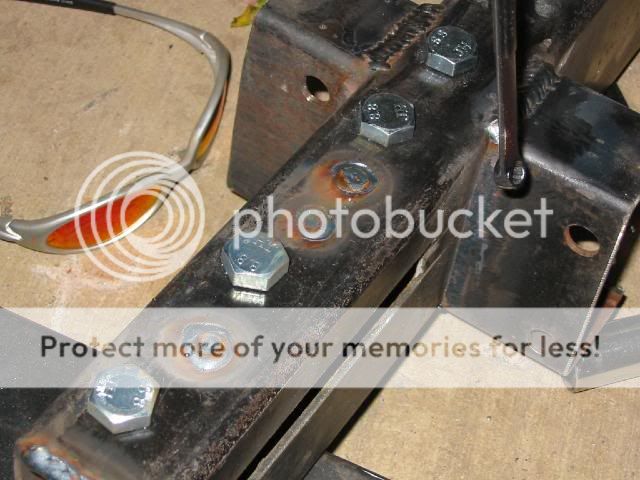

The 1/8" tube may seem a little on the weak side, but each bracket has 8 bolts in it, so it should be fine as well.

More progress tomorrow...

nah j/k, the two front ones can be easily accessed from the end of the tube, and the other two I will drill holes where the tip of the mig will slip in. All they need are some heavy tacks and everything should be copacetic.

The 1/8" tube may seem a little on the weak side, but each bracket has 8 bolts in it, so it should be fine as well.

More progress tomorrow...