VAhasnoWAVES

NAXJA Forum User

- Location

- Lake City, Mi

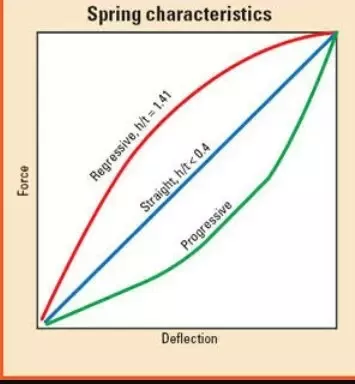

All springs are progressive, it's just whether they have a "linear" rate or more of a "geometric" rate

i think i know what you are trying to say... but terminology is important, and this statement is in fact, wrong.

a linear spring rate implies 1" of displacement for ever X amount of weight. which does not produce the same curve as a progressive spring.