-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My jeep build with photos over the last few years.

- Thread starter Evan03

- Start date

- Location

- Colorado

The real choice is 44 or full send 1 tons. The end results are nearly identical cash spent for either huge gains or slight gains. Not al 44s are equal... but even jk 44s aren't this super big jump in strength over a built 30.

Yes it's a stronger axle.. and for 35s it's a great combo. But putting that kind of money into a front end would have you nearly on 1tons dana 60 or 60/9" etc. The choice needs to be made now, are 35s the end game. Maybe 37s... but then you start breaking shit, ask the jk guys lol

37+, build a real axle. If 35s are your end game chromos or starting over on a dana 44 (also chromo) is the way to

go. Just be warned... there are threads and threads of JK owners batching about the front 44 and looking into rock jock currie etc due to its limitations. Sure you can have success like Gordo, but the 44 is NOT leagues ahead of a built 30...

Yes it's a stronger axle.. and for 35s it's a great combo. But putting that kind of money into a front end would have you nearly on 1tons dana 60 or 60/9" etc. The choice needs to be made now, are 35s the end game. Maybe 37s... but then you start breaking shit, ask the jk guys lol

37+, build a real axle. If 35s are your end game chromos or starting over on a dana 44 (also chromo) is the way to

go. Just be warned... there are threads and threads of JK owners batching about the front 44 and looking into rock jock currie etc due to its limitations. Sure you can have success like Gordo, but the 44 is NOT leagues ahead of a built 30...

No 35s is good. I decided this after following a buggy on 42s my jeep is the only fully locked jeep of the guys I go with. I followed the buggy everywhere while everyone else took easy lines and winched bounced and Yada. I don't think 37s are worth the minimal ground clearance gained. Sliders skid plates and sometimes luck.

I'm very happy with the 35s since breaking this 30 to shreds I've even thought of going back to 33s though I gota remember I was breaking shafts on 33s to.

I'm not convinced chromo shafts are the cure either.

I can't always drive like its on egg shells

I need to get lower wj ball joints and I despise the self adjusting uppers. I may go to all wj ball joints.

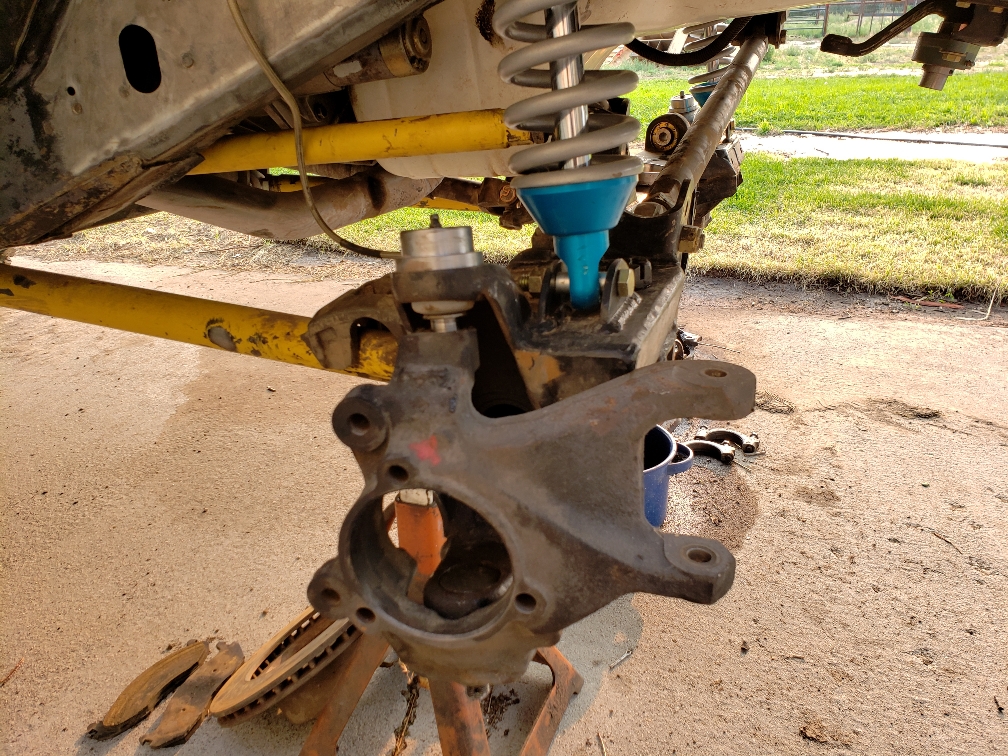

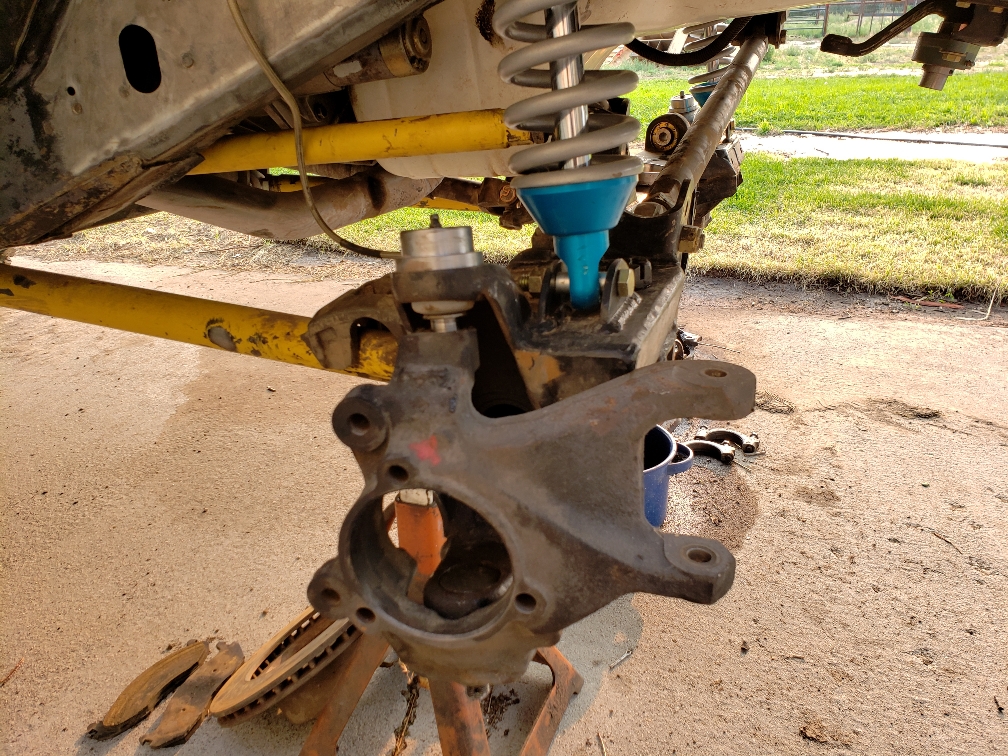

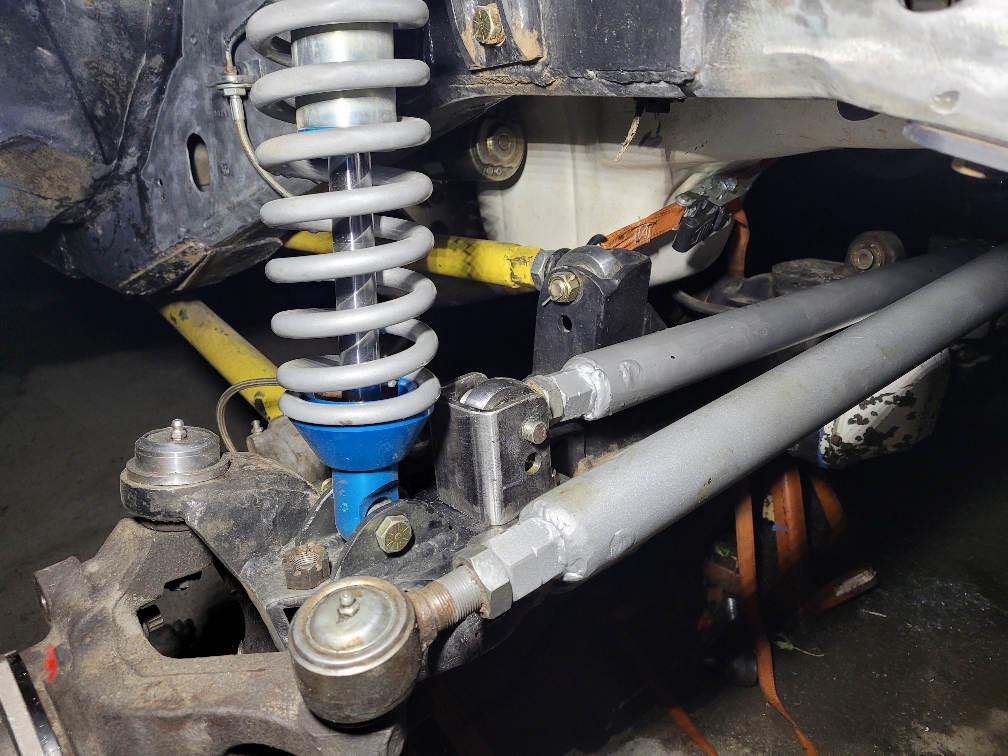

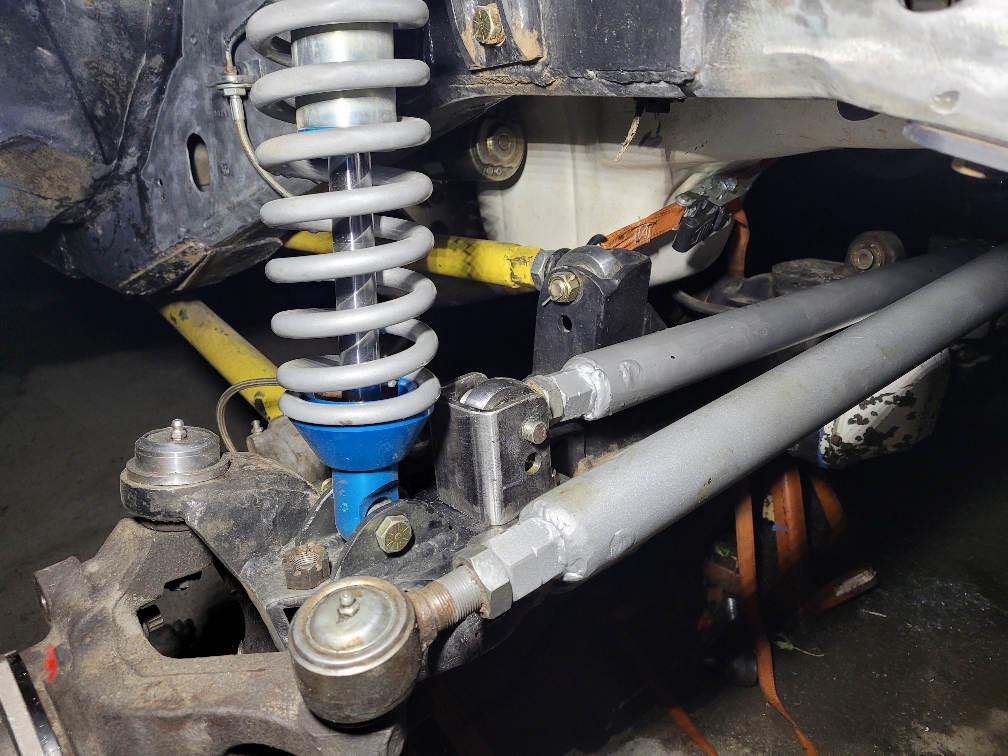

A quick knuckle test fit and shit. Guess I get to hack my lower shock mount up some.

Sent from my SM-G960U using Tapatalk

I'm very happy with the 35s since breaking this 30 to shreds I've even thought of going back to 33s though I gota remember I was breaking shafts on 33s to.

I'm not convinced chromo shafts are the cure either.

I can't always drive like its on egg shells

I need to get lower wj ball joints and I despise the self adjusting uppers. I may go to all wj ball joints.

A quick knuckle test fit and shit. Guess I get to hack my lower shock mount up some.

Sent from my SM-G960U using Tapatalk

- Location

- Virginia City, NV

Chomos just about guarantee that your next break will be a ring and pinion when running 35s on a d30. However chomos and 33s are a very reliable combo for d30.

Last edited:

- Location

- Murrieta

Chomos just about guarantee that your next break will be a ring and pinion when running 35s on a d30. However chomos and 33s are a very reliable combo for d30.

33s, 4.88s and ten factory shafts. Been running that combo since 09. Since that time i’ve only broken one ring and pinion on the dusy with the sierra folks, but that was because i was really bound. I agree with gordo 33s are the limit for a reliable 30. Just because you go bugger, if you drive with a heavy foot you’ll still break. Mike at Moab broke a 60 shaft on 35s.

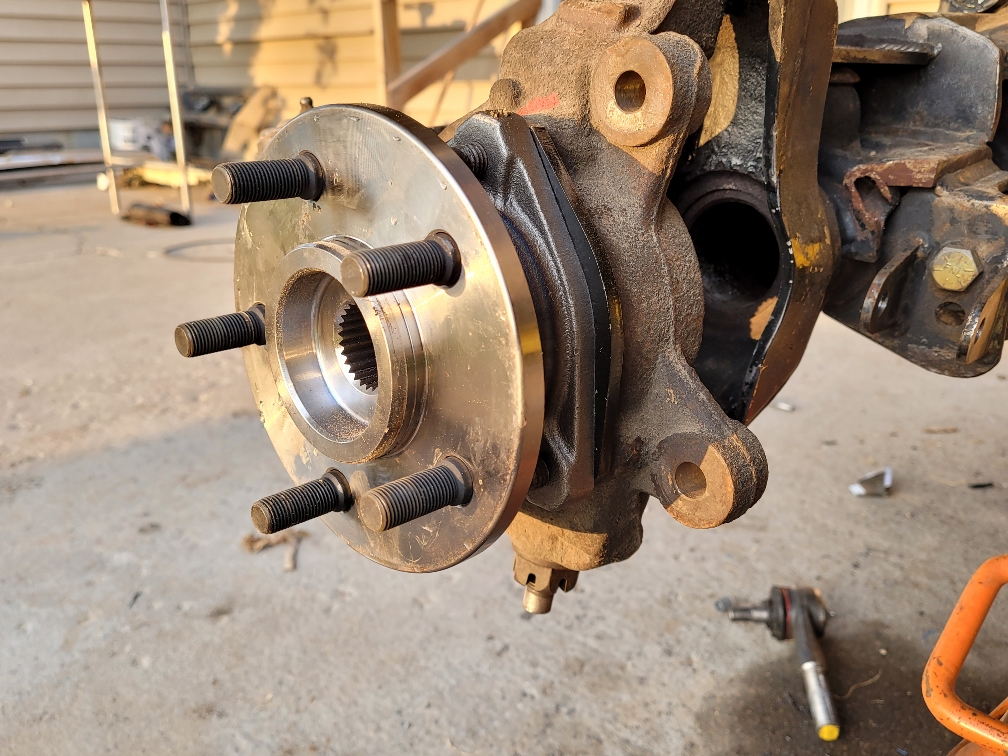

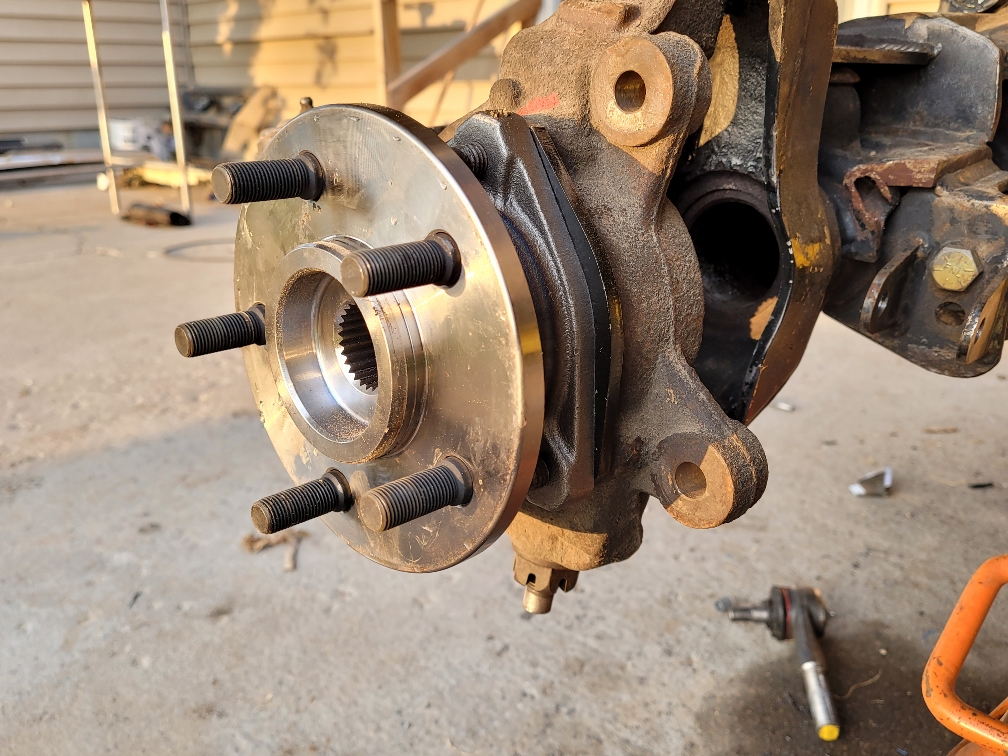

Looks like no issues with wj stuff and 15" wheels.

I decided to keep keeping on with the 30. Shafts, spacers, limit straps, reamer, think that's it. All do here Friday and anaks line goes along not quite having money to replace the ruined tire for another week or so.

Anak how's it go.

The most important thing is I want the axle seals to not leak and the junk yard rotors to turn true

Sent from my SM-G781U using Tapatalk

I decided to keep keeping on with the 30. Shafts, spacers, limit straps, reamer, think that's it. All do here Friday and anaks line goes along not quite having money to replace the ruined tire for another week or so.

Anak how's it go.

The most important thing is I want the axle seals to not leak and the junk yard rotors to turn true

Sent from my SM-G781U using Tapatalk

- Location

- In a strange land

Hows it going?

I can see the light at the end of the tunnel.

Last month I rented a 45' boom lift so I could trim my trees. Spent a solid week cutting out old, dead undergrowth. By the end of this week I should finally be done processing what amounted to enough to fill a 10 yard dump truck. I have had The Varmints cutting up the larger limbs for firewood while I have been feeding all the small stuff through a chipper. I haven't gotten anything done on vehicles in over a month.

I can see the light at the end of the tunnel.

Last month I rented a 45' boom lift so I could trim my trees. Spent a solid week cutting out old, dead undergrowth. By the end of this week I should finally be done processing what amounted to enough to fill a 10 yard dump truck. I have had The Varmints cutting up the larger limbs for firewood while I have been feeding all the small stuff through a chipper. I haven't gotten anything done on vehicles in over a month.

- Location

- Colorado

Fwiw I too had zero issues running 15" steelies with akebonos (brand new calipers from power stop via 4wp.com only 150 or so and didn't require a core charge vs going through powerstop direct). The spacer kit from iron rock is better than the garbage the previous owner had. Idk if you still want them spacers? Rusted crusted cracked and not very easy to line up- I'd feel bad sending em. Never got your Addy in a pm so figured you moved fwd... so far I'm happy with the RC ball joints. You get the right lower? Jk and dubj are the same fwiw.. helped to know that during my search.

Anak

Do you need dirt?

I'll be 4 weeks on a side job hopefully this weekend I finish and can bring you a few hundred yes of dirt.

Shooter

Have jks spacers on the way

Thank you for remembering me. Just went ahead and ordered some.

Sent from my SM-G781U using Tapatalk

Do you need dirt?

I'll be 4 weeks on a side job hopefully this weekend I finish and can bring you a few hundred yes of dirt.

Shooter

Have jks spacers on the way

Thank you for remembering me. Just went ahead and ordered some.

Sent from my SM-G781U using Tapatalk

- Location

- In a strange land

Thank you, but no need for dirt at this point, nor plans to need it.

If you wind up with a bunch of 3/4 crush gravel I could be interested.

If you wind up with a bunch of 3/4 crush gravel I could be interested.

OK sounds good. I have a few hundred yards of farm land to get rid of. I've hauled a couple hundred to a new house in Middleton hoping finish fine grading there Sunday.

We rarely have extra rd mix normally if we do it's one bucket and it just gets thrown inbthectruck with dirt.

Sent from my SM-G781U using Tapatalk

We rarely have extra rd mix normally if we do it's one bucket and it just gets thrown inbthectruck with dirt.

Sent from my SM-G781U using Tapatalk

Baseball bat drag link burned. Though I was tired and taking a nap would have been more productive it should have been longer.

I assumed wj and xj had very similar if not the same tie rod length. It appears theure different by like 3"s xj length makes wj severely toed in.

I set drag link length at full lock to passenger side with out checking toe this makes the drag link to short.

Maybe there's enough adjustment.

Maybe I'll redo it all since this is salvaged steering anyways.

Sent from my SM-G781U using Tapatalk

I assumed wj and xj had very similar if not the same tie rod length. It appears theure different by like 3"s xj length makes wj severely toed in.

I set drag link length at full lock to passenger side with out checking toe this makes the drag link to short.

Maybe there's enough adjustment.

Maybe I'll redo it all since this is salvaged steering anyways.

Sent from my SM-G781U using Tapatalk

Monkey grip shafts ohhh I mean national gear motive well shit I guess ten.

I did some research and bought the cheapest I could find after realizing none of these names actually make shafts.

So ordered monkey grip on ebay a ten box ends up at the door.

I'm slightly but hurt because the ten axle seals I bought were junk and never knowingly buy anything ten imports.

The ujoints do appear to be Spicer with full circle clips

But I guess.

Sent from my SM-G781U using Tapatalk

I did some research and bought the cheapest I could find after realizing none of these names actually make shafts.

So ordered monkey grip on ebay a ten box ends up at the door.

I'm slightly but hurt because the ten axle seals I bought were junk and never knowingly buy anything ten imports.

The ujoints do appear to be Spicer with full circle clips

But I guess.

Sent from my SM-G781U using Tapatalk

BTW there's has been discussion on weld or not weld hub spacers, after bolting these in I think it's just fine to not weld.

I may not weld for not welding drivers knuck because I think I'm going to replace it due to my shitty reaming job.

Might not weld eithere.

either.

Put the aluminum wheels on to easier lock in toe

I drilled wj rotors went pretty good

Finished with a 5/8 bit.

Also locked down track bar length. It's 35" if I'm not working tomorrow I might get to fabbing axle and frame brackets to bolt it in.

Track bar was 31" 4" longer and flatter can't hurt and is same length as new drag link.

Sent from my SM-G781U using Tapatalk

I may not weld for not welding drivers knuck because I think I'm going to replace it due to my shitty reaming job.

Might not weld eithere.

either.

Put the aluminum wheels on to easier lock in toe

I drilled wj rotors went pretty good

Finished with a 5/8 bit.

Also locked down track bar length. It's 35" if I'm not working tomorrow I might get to fabbing axle and frame brackets to bolt it in.

Track bar was 31" 4" longer and flatter can't hurt and is same length as new drag link.

Sent from my SM-G781U using Tapatalk

frijolee

NAXJA Forum User

- Location

- Big Island, HI

Just stopping by to say I love this build and all the DIY shenanigans within. Anyone who's willing to build their own stuff is pretty damn solid in my book. Nice lookin fab bench too. Did you make that as well?

Frijolee

Thanks I love building something from nothing seeing it my head and make it happen in front of me. Sometimes it's cheaper to buy but not near as much is learned. Sometimes built stuff is better but sometimes it's not.

Yes that is a bench I did 12- 15 years ago just recently set the metal saw flush on it and I stole the center shelf material. Bench is on castors. Been meaning to put wood or something back in.

Sent from my SM-G781U using Tapatalk

Thanks I love building something from nothing seeing it my head and make it happen in front of me. Sometimes it's cheaper to buy but not near as much is learned. Sometimes built stuff is better but sometimes it's not.

Yes that is a bench I did 12- 15 years ago just recently set the metal saw flush on it and I stole the center shelf material. Bench is on castors. Been meaning to put wood or something back in.

Sent from my SM-G781U using Tapatalk

Brackets aren't burned. Have to lower frame side about 1" maybe 1.5.

As pictured track bar is 1deg ish steeper than drag link. Also contacts oil pan. Hits 1/2" before shock bottoms. Might have to live with alitt contact if it still hits after track bar is locked in

Track bar frame side is fabbed no holes drilled yet so I can drill exactly to match drag link.

Found a tire to guess I'll mount it the old fashioned way, tire irons well after working over all the burs on the wheel since tires was run half off the bead actually half off the wheel

Sent from my SM-G781U using Tapatalk

As pictured track bar is 1deg ish steeper than drag link. Also contacts oil pan. Hits 1/2" before shock bottoms. Might have to live with alitt contact if it still hits after track bar is locked in

Track bar frame side is fabbed no holes drilled yet so I can drill exactly to match drag link.

Found a tire to guess I'll mount it the old fashioned way, tire irons well after working over all the burs on the wheel since tires was run half off the bead actually half off the wheel

Sent from my SM-G781U using Tapatalk

Similar threads

- Replies

- 5

- Views

- 83

- Replies

- 1

- Views

- 288

- Replies

- 65

- Views

- 17K

- Replies

- 16

- Views

- 6K