RWKHausSupply

NAXJA Forum User

- Location

- yorba linda, Cali

well let me first say that dedenbear kuckles at 400degreee's will Not just slip on the tubes as they say they will. I have to take a flap wheel and take some OD off. I thought I had enough on one side and then put some super snoot grease on the tube and pulled the knuckle out of the oven and it barely slid on. just as I was taping it to get the 5deg from it, it seized!

Dedenbear insisted that at 400deg and a 3"OD tube that I had about a hour, at least 30 min of positioning time. WRONG, about 5-10 sec.

the second side I was a bit more rushed to do, as it was 9:30 last night. When I slide that one on I had about 3 sec of positioning. Not enough. I had it set to 3 deg and paniced. Grabbed the 5lb mini sledge and beat it to 5deg. just about 5 sec later there was no moving it no matter what I bet.

SO the pretty god aweful orange is all beat to crap on one side. Just means that I flap wheel it all off and either have the entire housing powder coated or just paint it when done here.

Again, heat alone is not enough and if you do use heat to expand the knuckles liek the manuf says to, you better be quick!

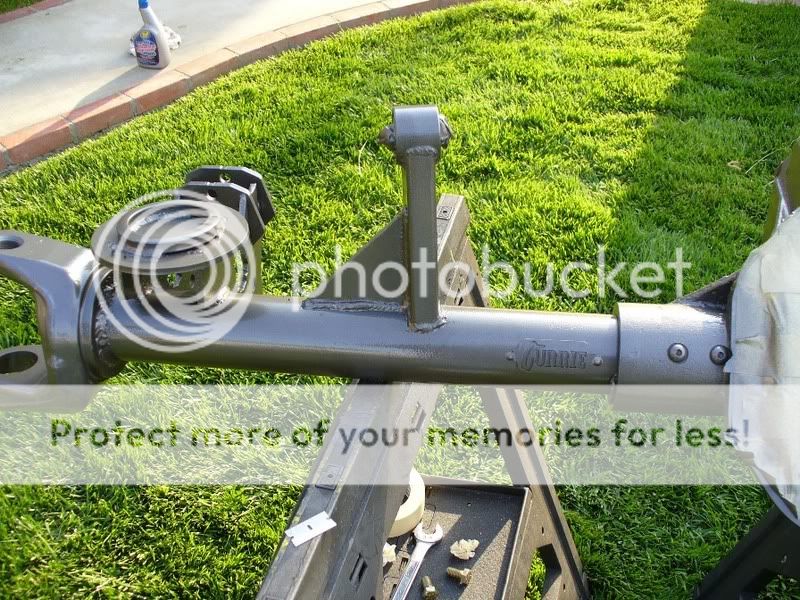

Heres the only picture from last night. When all said and done. Pinion at the tc and 5deg on the knuckles. I did only 5 cause I may lower the pinion a tad and get around 7-8 from the knuckles.

Dedenbear insisted that at 400deg and a 3"OD tube that I had about a hour, at least 30 min of positioning time. WRONG, about 5-10 sec.

the second side I was a bit more rushed to do, as it was 9:30 last night. When I slide that one on I had about 3 sec of positioning. Not enough. I had it set to 3 deg and paniced. Grabbed the 5lb mini sledge and beat it to 5deg. just about 5 sec later there was no moving it no matter what I bet.

SO the pretty god aweful orange is all beat to crap on one side. Just means that I flap wheel it all off and either have the entire housing powder coated or just paint it when done here.

Again, heat alone is not enough and if you do use heat to expand the knuckles liek the manuf says to, you better be quick!

Heres the only picture from last night. When all said and done. Pinion at the tc and 5deg on the knuckles. I did only 5 cause I may lower the pinion a tad and get around 7-8 from the knuckles.