baseballneal86

NAXJA Forum User

- Location

- Damascus, MD

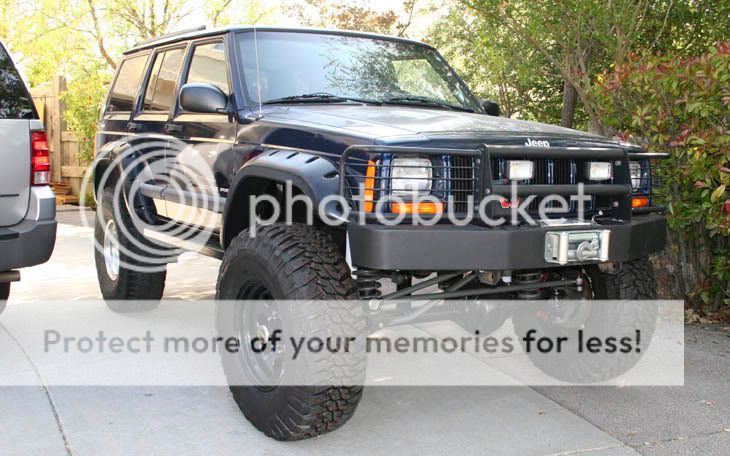

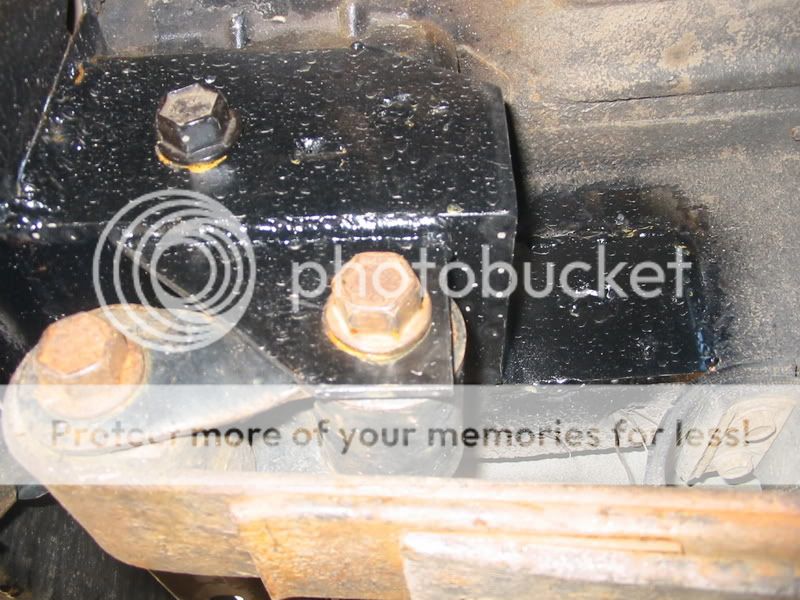

After reading about the unloading problems that are characteristic of a radius arm design, I'm starting to rethink my suspension plans. I know the D44 with cast wedges is rather undesirable for building a link suspension on but it's what I have. How practical would it be to weld link mounts onto the existing C-wedges? I know brianho13 did his this way. What compromises would I be making by welding to the cast?

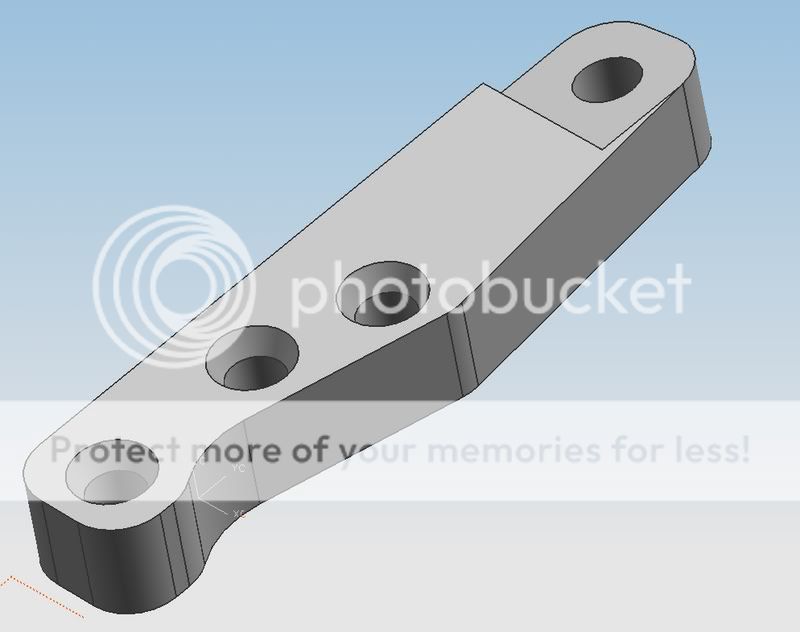

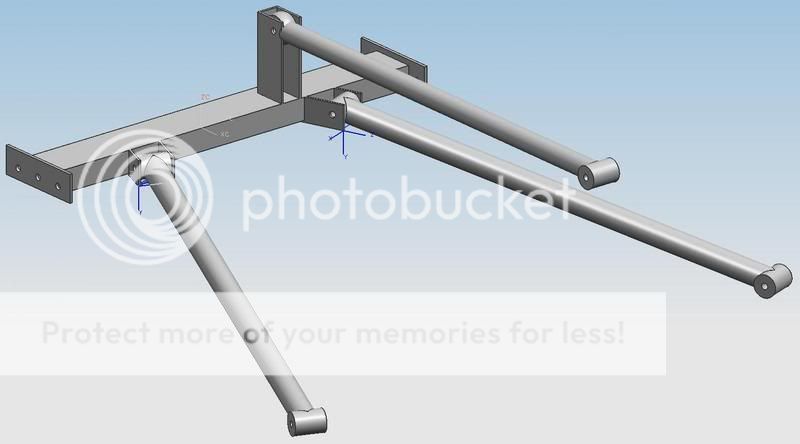

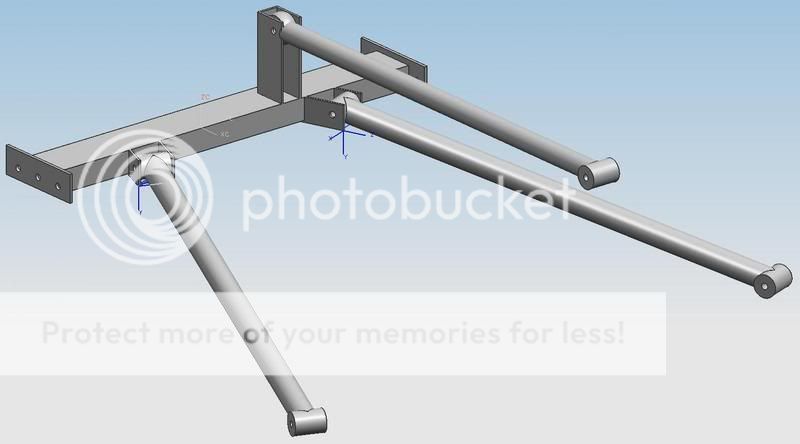

The new suspension design that I would like to run is a URF-inspired 3 link. I have an AW4 tranny so I know the upper arm clearance will be super tight. To help with this I'd like to run a small diameter, thick wall tube.

Thoughts?

The new suspension design that I would like to run is a URF-inspired 3 link. I have an AW4 tranny so I know the upper arm clearance will be super tight. To help with this I'd like to run a small diameter, thick wall tube.

Thoughts?