V84BAJA

NAXJA Forum User

- Location

- Orange County,CA.

What kind of travel numbers ya looking for,16-18 inches?

What kind of travel numbers ya looking for,16-18 inches?

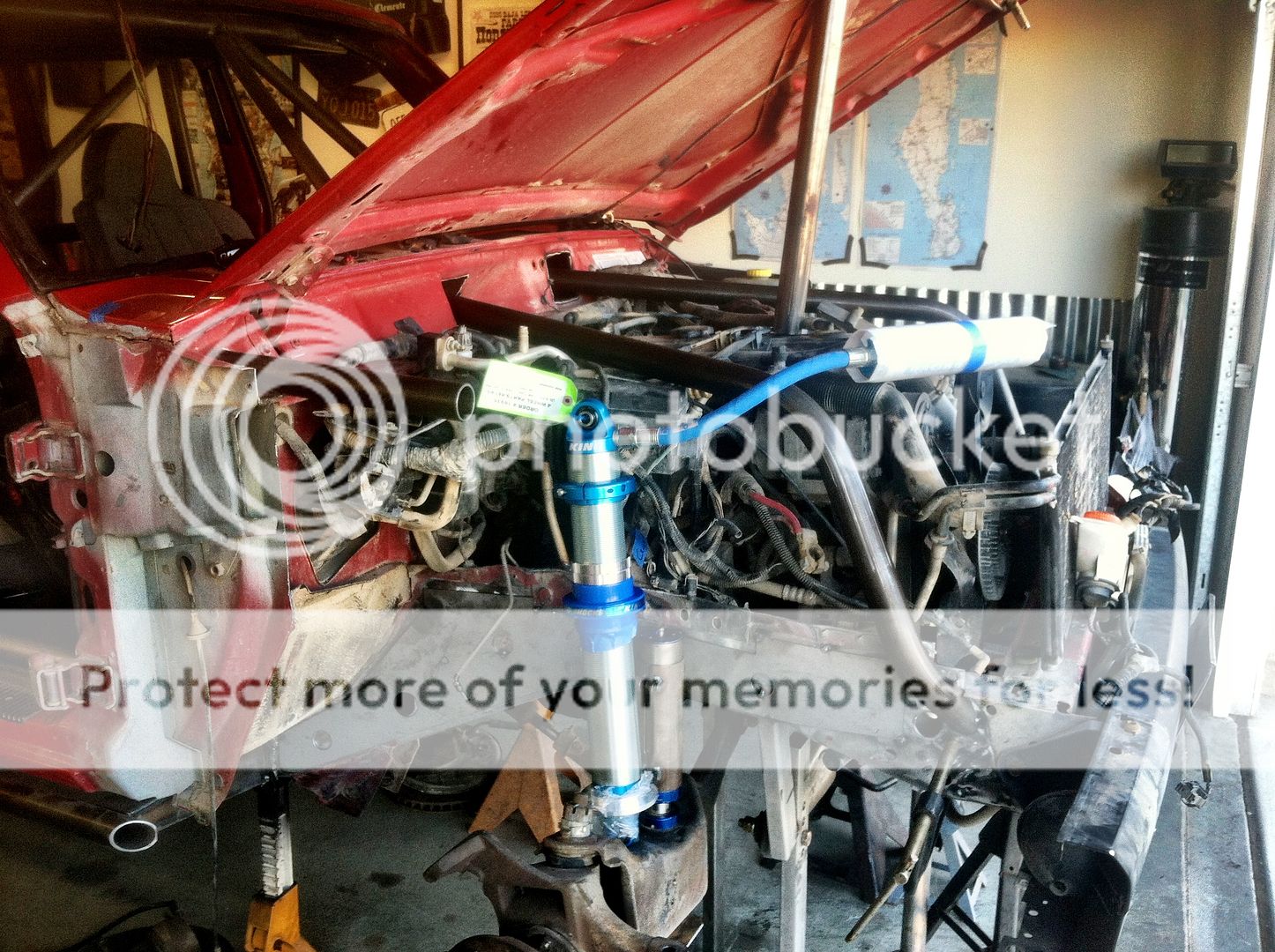

I love the engine cage start...great design. How difficult is it going to be to pull the engine if needed though?

I love the engine cage start...great design. How difficult is it going to be to pull the engine if needed though?

Love the build guys.

Had a couple questions before I started this same conversion on my jeep.

Are you planning to keep the stock angles or cutting and turning the beams?

Did you box all sides of the the frame rails or just the outsides?

What size steel do you plan make the actual crossmember out of?

Thanks

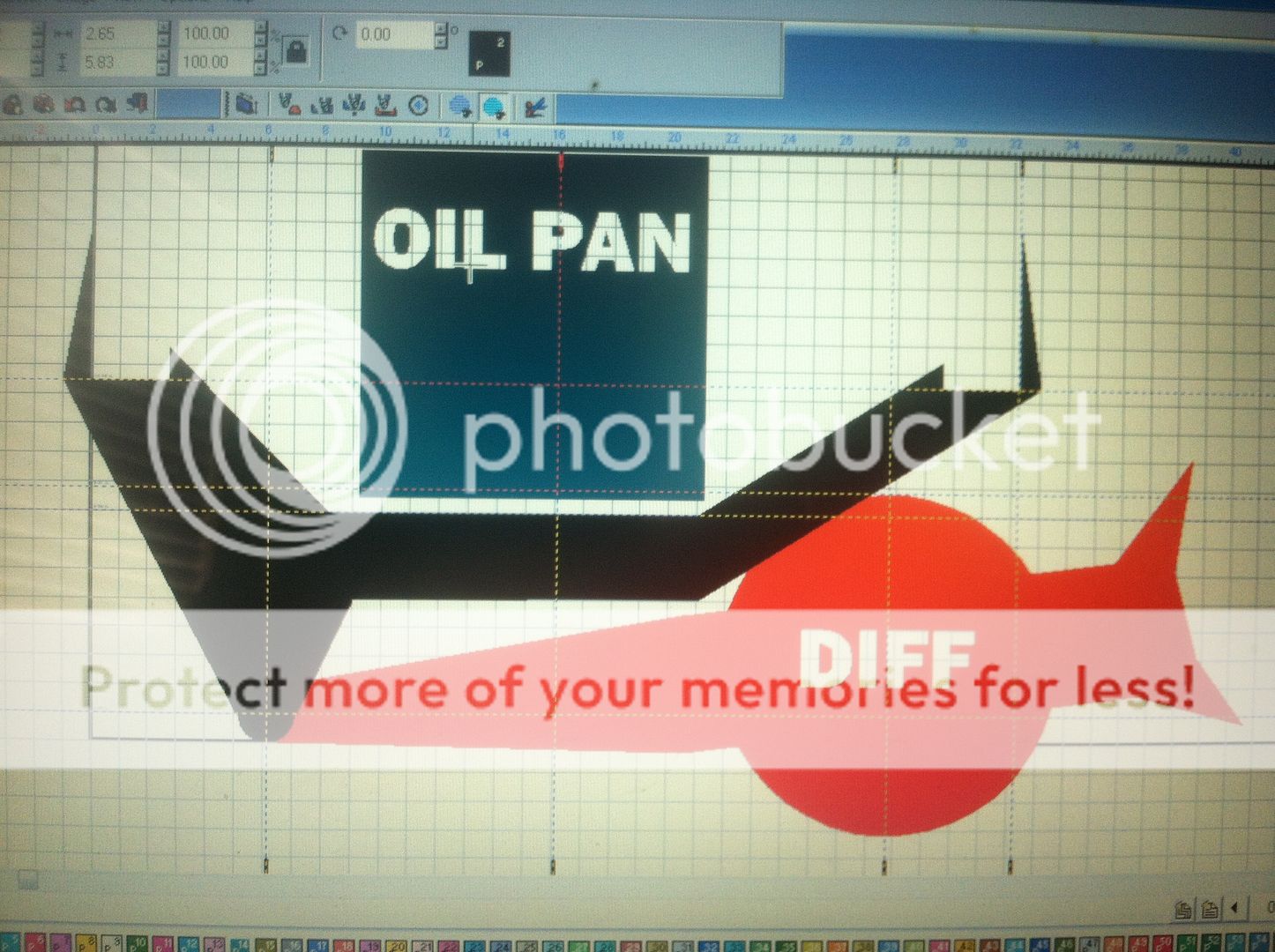

I was looking for the "and the crossmember will be available as a kit" part of that last post

if they get just the crossmember laid out on the CAD why not make some bucks as a weld it yourself kit? I'd be willing to drop a hundo or so to keep from having to figure it out for myself. I'm going the same exact direction with my chassis (plus an LS motor) and it would save me months of R&D with my limited garage time.

hell i'd pay 50 bucks for just the file and get it cut myself.

quiet you! hahaYou cour buy a Bronco and save your self te time ad energy ...... Hahahahahaha. Sorry, I had too.

More pics of this bad ass Cherobronco!!