Ramsey

NAXJA Forum User

- Location

- Shreveport, LA

thanks for the new desktop :wave:

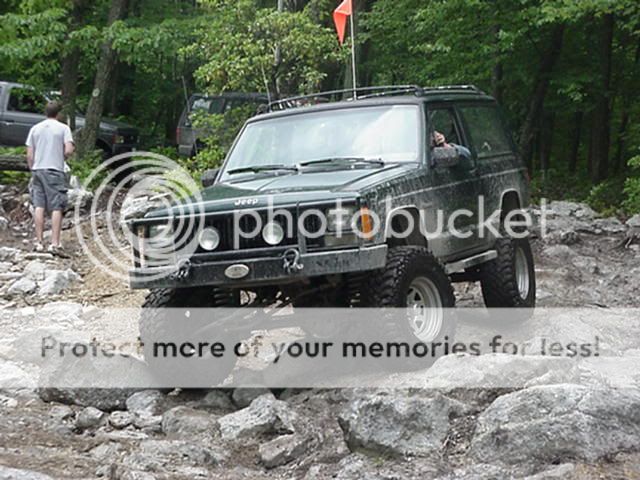

BrettM said:that is a very nice bumper cherokeekid!

I like mine for simple, light and strong. It's just a piece of 4x4x1/4 angle, cut and re-welded to angle the side pieces back a little, then cut an angle on them and weld on some tube. It was super easy to make and i've bashed it a lot with nothing more than scratches.

click picture for full size picture: