Yeah, my mileage has been in the toilet for a while, I think I'm getting around 10 or so. I stopped figuring it on every tank because it was depressing; I was near 15 beforehand.

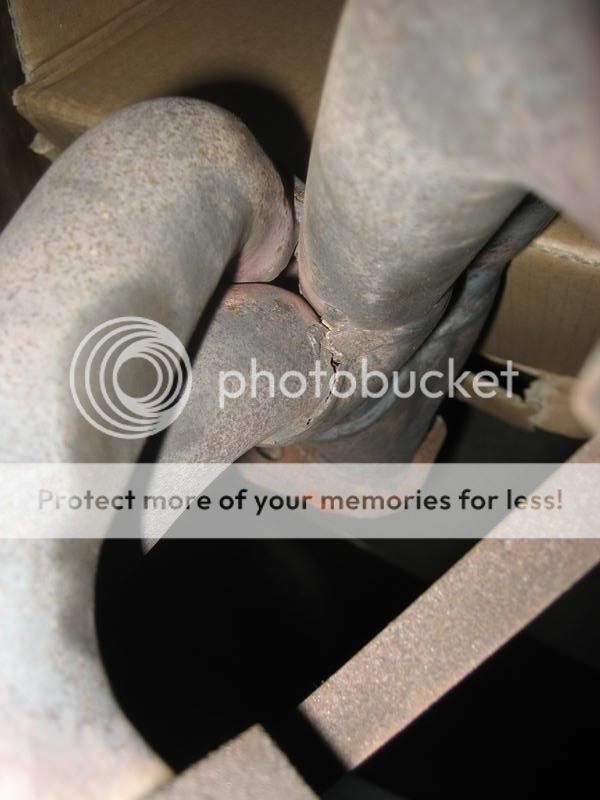

I'd like to have a new downpipe bent up with one of those flex fittings in it, that sounds like it couldn't hurt anything to have it done, it's just that all of this has taken a lot longer than I expected and cost me more too. Although, I am working on a Jeep, so that is all to be assumed from the beginning.

It kind reminds me of a few years back when a buddy of mine and I were doing some carpentry work on the side. After a few weekend jobs, we realized that the most accurate way to judge how long our work would take was to figure it out step by step, double check it, and then double whatever number of hours we came up with. By doing that, we were nearly right on every time. Kinda pathetic though.

Maybe I'll pull a pipe from the junkyard and have that matched by a shop so that I can keep driving it while it's being made.

This is the tail end of a winter project to replace my 8.25 with a D44. I'm kinda far away from the rear at this point in the game, but it's still up on jackstands and I'm waiting for parts on every piece of the project. I'm waiting for my shims to come in so that I can bolt the axle all up; I'm waiting for the engine mount to show up at the dealer so that I can put my header back in; I need to replace the clutch master cylinder in my little runaroundHonda, but I don't want to start that until I'm sure that my XJ is road worthy. Yikes.