blistovmhz

NAXJA Forum User

- Location

- Vancouver, BC

I like cowls if they go with the factory body lines. wouldn't be hard to do on an xj and it would be a subtle look

Heh. 6" cowl and subtle don't belong in the same sentence.

I like cowls if they go with the factory body lines. wouldn't be hard to do on an xj and it would be a subtle look

Hey, where's all YOUR videos anyhow? I can really only find 4 or 5 videos of v8 XJ's showing off the power, and they're all really poorly shot videos.

Also, what'd you do for your t-case linkage? The distance from my shifter to the case is just too short to do anything with because of the AA trans/case adapter. I'm almost considering cable shifting it.

Would this kit do you any good, or is it purely intake manifold clearance?

Heh. 6" cowl and subtle don't belong in the same sentence.

I don't have many, but the ones I have on my photobucket main page. Find it through one of my signature links. I had really good luck using the Novak shifter for my t-case. I was able to shape the lever to fit thru the stock console hole and it provided me with accurate and solid shifts.

This is the best price and easiest conversion I have seen for bracket relocation.

Don't take it as gospel or anything but I'd think that when the computer loses knock sensor, it pulls ignition timing to play it safe. Might start with fixing known problems (knock sensor code) and go from there.

Also

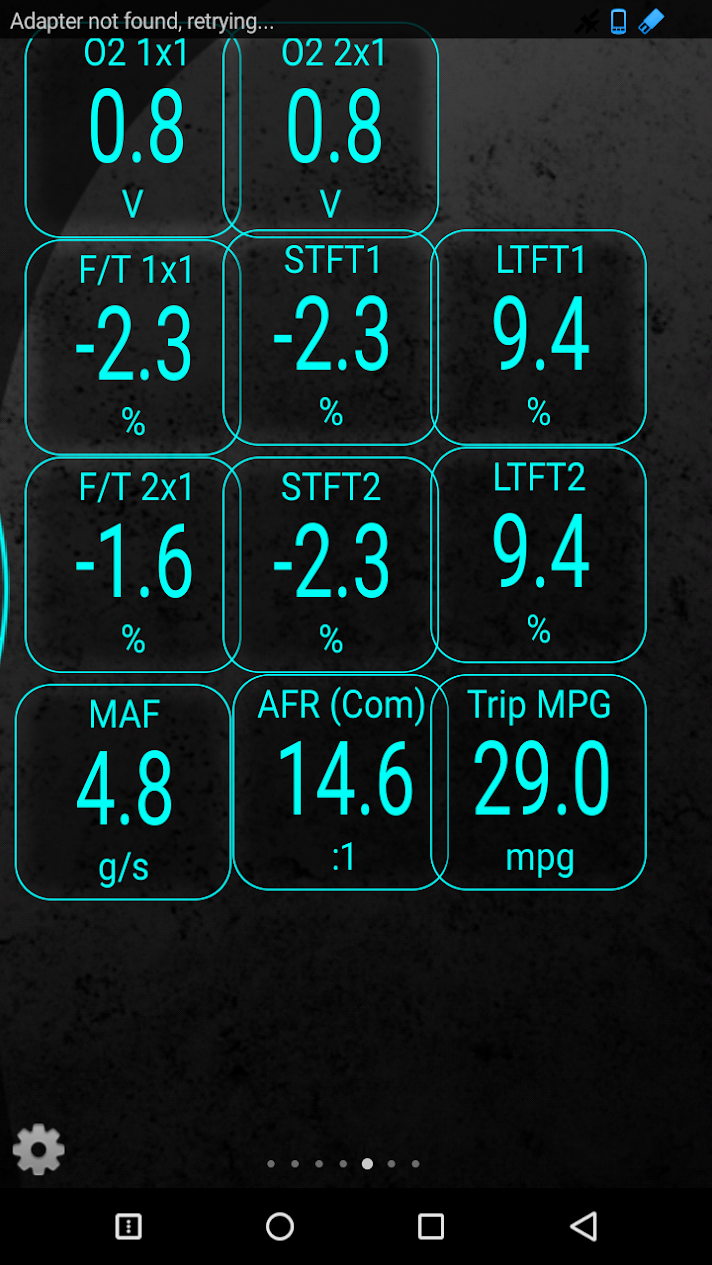

I don't think a stock 5.3 is supposed to burn out 35s, is it? I'm running a 4.8 (de-stroked 5.3) in a truck that's 4100 lbs with me + a trip to the dump's worth in the back of the truck. It feels quick but hasn't yet made any tire smoke - and that's on 29s

The 3550 is rated to take 300 ft-lbs, the 5.3 makes 330. You could use it but I wouldn't expect a long, happy life out of a used 3550.

Also, the 5.3 doesn't require anything aftermarket to put a manual behind it. The crank is no different than a 6.0 crank. I suspect it never had a manual because the 5.3 / 4L60E combination didn't "need it" the way a 4.8 truck did and the fleetwide emissions go down when you force automatics on people. The 6.0 trucks (3/4 ton, 1 ton and a handful of 1/2 ton "HD" units) had manual because you kind of have to sell a manual in the medium duty truck market.