blistovmhz

NAXJA Forum User

- Location

- Vancouver, BC

Hey all.

Lots of SBC 5.3 swaps out there (none in Canada it seems), but most claim to expect to spend a minimum of $5000 to do it wrong, and $10000 to do it well. I never buy other peoples numbers. Anywho, I figure I may as well document it. If I fail, it'll be a good lesson to someone else, and if it works out, it's a bit of a slap in the face to guys who "claim" to spend $20k to get it done.

I'd call my fabrications skills "barely adequate", but I researched the hell out of this and I'm pretty confident it'll go mostly smooth.

My 98 XJ has 6.5" up, long arm, 1 tonne OTK/OTA cross over steering, WJ knuckles, Akebono front brakes, KJ rear brakes on a D44. Both axles lunchboxed at 4.56. Uni-frame stiffeners and bumpers should help with torsion from the new motor. Rear swing-out bumper goes 28" into the frame rail. The rear cross member was reinforced with 1/8" plate, and the rails were also plated in from the CM to where the rail starts dropping down. I'll get the bit between my plating and the stiffeners burned in while the fuel tank is out for the pump upgrade. Front end still needs plating, which I'll probably do after the swap is complete, unless I have to notch the frame for some reason.

The plan:

Engine: - $650: 5.3L (non flex) from a 2005 S1500. Came complete with transmission, accessories and ECU.

Transmission: 4l60e that I think is from the same truck.

Transfer case - $75: hybrid np231

Motor mounts - $220: Novak

Headers - $327: Novak/Sanderson

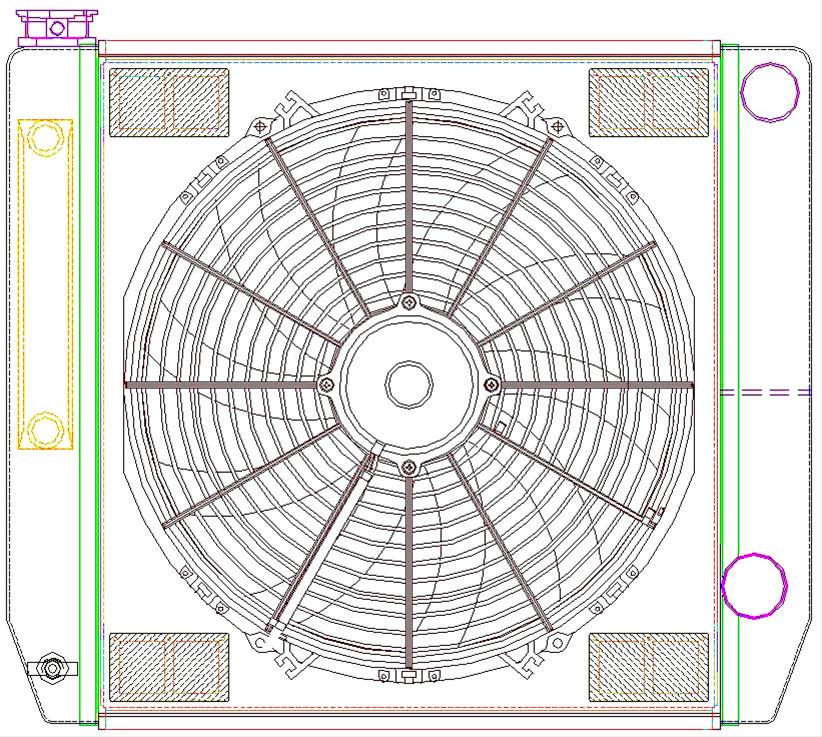

Radiator - $650: GRI-CU-28182-TS (Radiator and Fan, Aluminum, Crossflow, 2-Row, 22 in. Width, 19.0 in. Height, 5.313 Thickness, Single Fan) - Should fit between the lower frame CM and the stock rad support, with modification. Good to around 400HP.

Auto shifter: No idea yet. Probably a stock XJ floor shifter if I can find one.

Fuel delivery - $150: Used 255lph Walbro in tank pump (from my buddies Mustang), and 25' of 3/8 nylon fuel hose, with the cheap press fit Dorman connectors. Running a C5 regulator/filter.

I'll post links/part numbers for everything I use when I've finalised everything and am sure it's going to work.

Explanation on parts:

Motor/trans/ecu/accessories were $650. The guys seemed legit, but if not I'm not super worried. I'll spend $650 to know my Jeep is ready to drop in another SBC. The motor turned over by hand with the spark plugs removed. Heads look to be in good condition and fairly clean. Block has a lot of external rust but the little bit I can see inside without tearing it apart looks good. The guy said something about the trans controller not being correct or something, but I didn't really ask him to elaborate. I'm guessing someone bolted the wrong one on. Cheap to pull from the wrecker anyway. Hell, a whole new trans there is only $80.

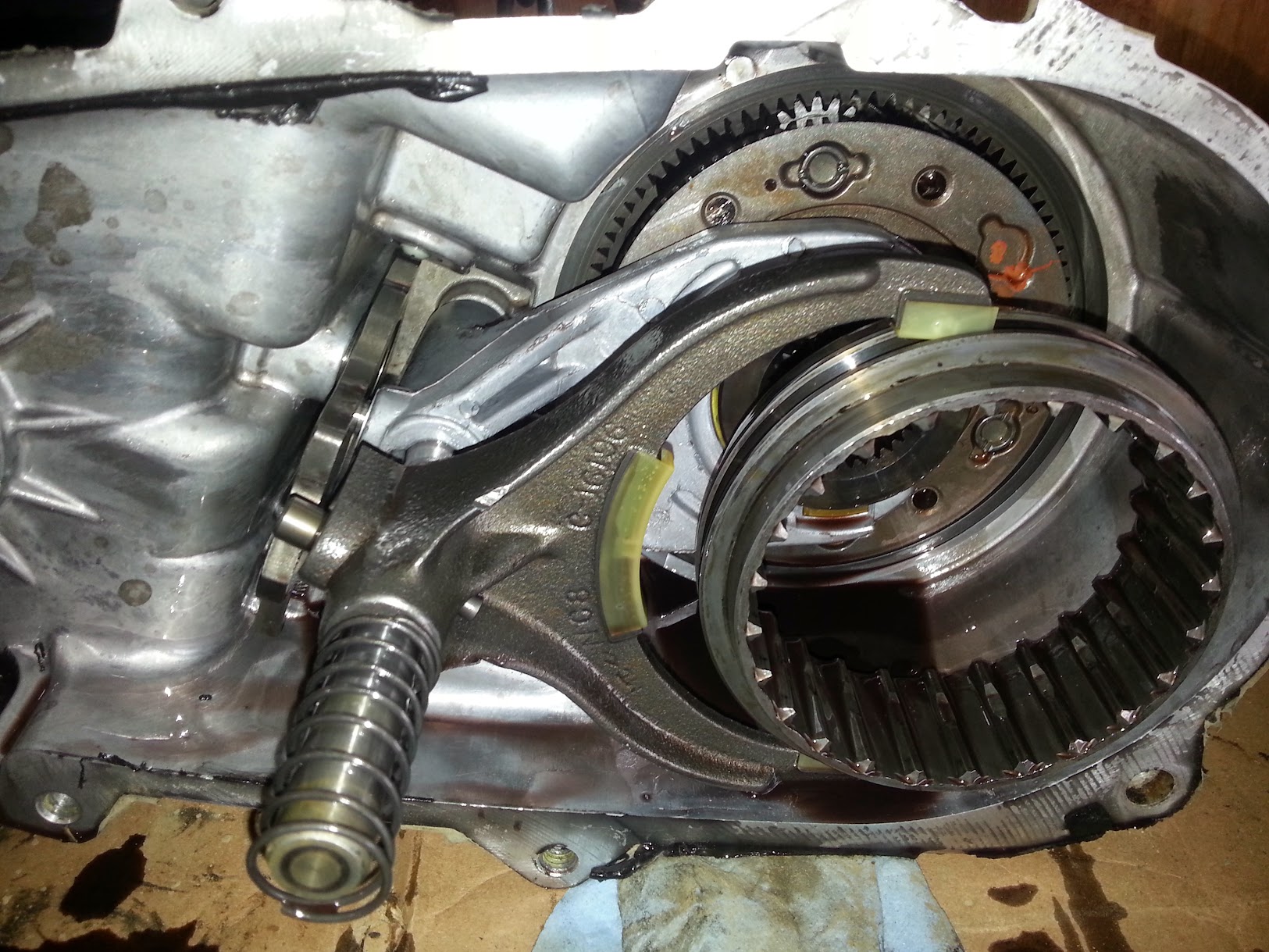

I didn't want to go for an automatic, but adapting a 5.3 (never shipped with manual) is WAY more work. I could've used my AX15, but I'd have to find a flywheel, and that's a whole other can of worms as the 4.8 and 6.0's had the crank output slightly further in or out from the block (I don't remember which). In the end, I'm happy to just stick an auto on for now and if I hate it, I'll spend the time later for a manual.

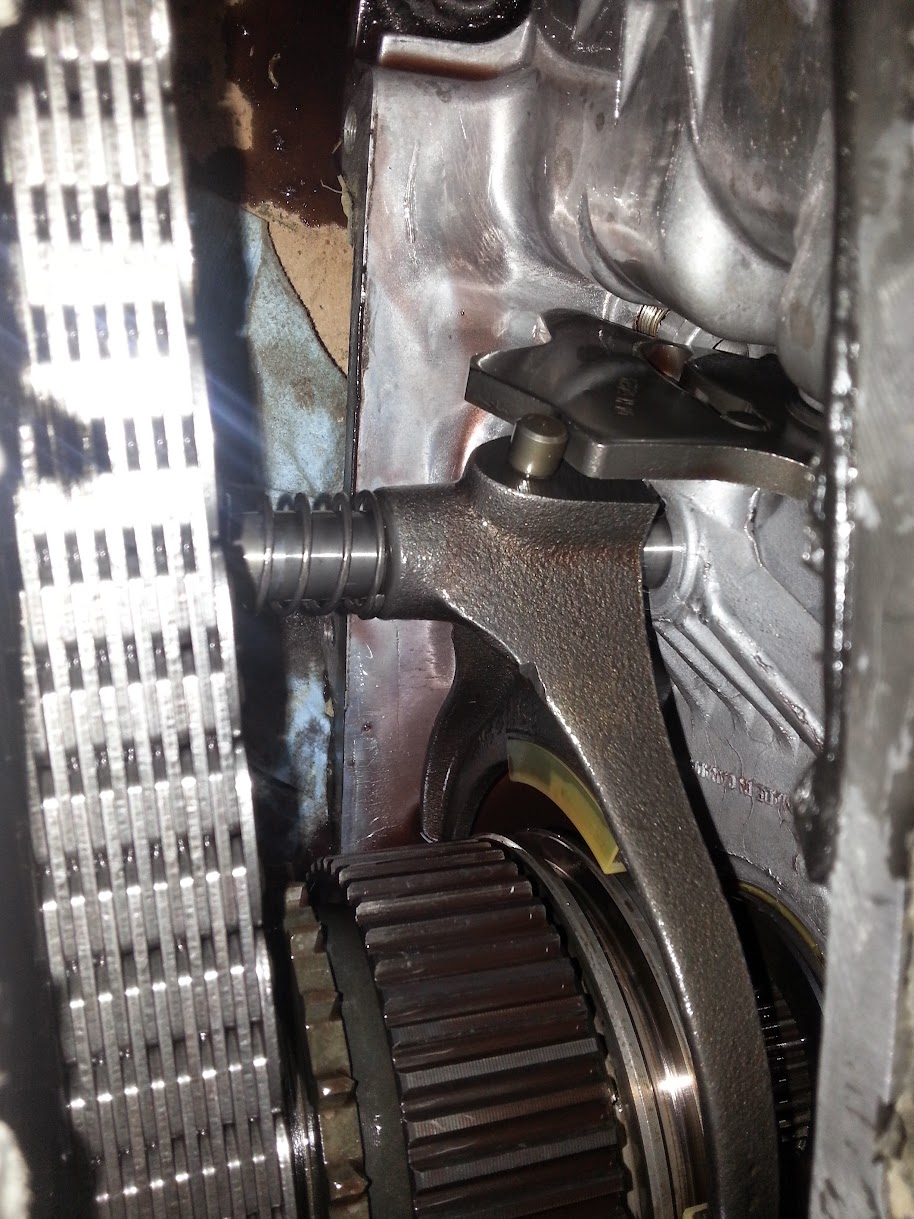

I'm going to try the hybrid NP231/241c/j mainly because once done, it SHOULD be a fairly stout case and has massive aftermarket support. I was going to just use a 241c but couldn't find an SYE, or trans/case adapter that I'd be able to have at my door in less than 6 months. **** that. If I break a part, I don't wanna be out for 6 months to a year waiting on JBconversions. The hybrid 231 should be slightly stronger than a 231c (already stronger than the 231j) because of the 27spline, six pinion planetary from the 241c.

I waffled on the motor mounts and headers for a long time before ordering from Novak. I don't like that they design their products to NOT work with anything else. Ultimately though, I've never seen a 5.3 in an XJ and everyone talks about how little clearance there is between the block and the frame. Now that I have the mounts and headers and my Jeep engine pulled, I realize I could have easily fabbed up some mounts myself in an hour or so that would work with the Novak headers, or a combination of two different sanderson headers. Next swap probably won't be using Novak.

Radiator. *sigh*. The single most expensive part of this swap. I've had cooling issues for too many years and didn't want to **** around. I figure a 400hp rad should pretty much guarantee that cooling won't be the roadblock here. There is 22.125 inches from the passenger frame rail to my Dakota steering box. This cooler is supposed to be 22". I'm crossing my fingers. There is exactly 19" from the lower part of the CM to the bottom of the rad support. The CM tapers up at the frame rail, so I'll have to do some cutting to get it all in, but I think it's doable.

Shifter: Really no idea. I looked at all the conversion kits and hated them. I'm not a "stock look" weenie by any means, but the stock XJ auto shifter is probably the best option. I may change my mind when I can't find one .

.

The Transmission to T-case adapter was for me, the 800lbs gorilla. There are heaps of ways to stick a driveline together, but ultimately it was the GM VSS that killed me. The ECU needs that 40t reluctor signal to figure out shift points on the trans. I could do some magic with the stock Chysler Speedo, but I've heard this rarely works well and you end up with buggy shift points or poor fuel economy. I wanted a GM VSS either in the t-case or on the transmission. Ultimately I could've waited 8-2000 months for JBconversions np231/241 SYE with GM compatible VSS, but I don't wanna wait. Besides which, what happens if I want to change out the case later? New VSS is what. Advance are the only guys I could find that have a trans/case adapter that puts the VSS reluctor on the transmission output (novak makes you swap your 27spl trans output for a 23spl output with a VSS reluctor, so it'll mate up to the NP231j. This is retarded. AA retains the stock 27spl output so you just need to bolt the 40t reluctor to the stock output, stick their trans/case adapter on, swap case inputs to a 27spline (way easier than swapping out a trans output), and bolt together).

Status:

I have the engine (complete except for tensioner, belt, spark plugs, intake tube/filter), transmission, 3 transfer cases and a 241c input gear (np231j 95+, np231j 94-, np231c 94-, np241 input/planetary 2000+ I think). Motor mounts and headers are installed on the motor.

Advance ****ed me and told me everything in my trans/case kit was in stock when I ordered and that it'd be here by ... two days ago. Now it won't be shipping for another week because apparently they forgot that they didn't have any of the parts in stock, and that the adapter still needed to be manufactured. ****arz. Advance was actually really decent about helping me figure out everything I needed to know about my driveline conversion. Maybe this stock issue was just an oversight and not just a sales thing.

All in all, I'm about $1950 into the swap and have most of the expensive stuff already on my bench. Perhaps I'm being overly optimistic. I still need lots of little stuff, but I really don't see this running over $5000 unless the motor is destroyed. Even then, that'd put me out less than a grand and I'd still probably be under the $5k mark.

Lots of SBC 5.3 swaps out there (none in Canada it seems), but most claim to expect to spend a minimum of $5000 to do it wrong, and $10000 to do it well. I never buy other peoples numbers. Anywho, I figure I may as well document it. If I fail, it'll be a good lesson to someone else, and if it works out, it's a bit of a slap in the face to guys who "claim" to spend $20k to get it done.

I'd call my fabrications skills "barely adequate", but I researched the hell out of this and I'm pretty confident it'll go mostly smooth.

My 98 XJ has 6.5" up, long arm, 1 tonne OTK/OTA cross over steering, WJ knuckles, Akebono front brakes, KJ rear brakes on a D44. Both axles lunchboxed at 4.56. Uni-frame stiffeners and bumpers should help with torsion from the new motor. Rear swing-out bumper goes 28" into the frame rail. The rear cross member was reinforced with 1/8" plate, and the rails were also plated in from the CM to where the rail starts dropping down. I'll get the bit between my plating and the stiffeners burned in while the fuel tank is out for the pump upgrade. Front end still needs plating, which I'll probably do after the swap is complete, unless I have to notch the frame for some reason.

The plan:

Engine: - $650: 5.3L (non flex) from a 2005 S1500. Came complete with transmission, accessories and ECU.

Transmission: 4l60e that I think is from the same truck.

Transfer case - $75: hybrid np231

- np241c - $15: 27 spline, long shaft, wide bearing (I beleive it came out of a late 90's Sierra S1500). They didn't know how to charge me for this, so they called it a flange adapter or something.

- np231c - $75: Most of the stronger internals, and probably the shift lever for a direct linkage (linkage will be reversed (pointed up) and connected to a modified floor shifter with some rod ends) - Donor was an early 90's S10. - This cost me $75 at the wrecker during their 50% off sale.

- np231j - $0: case, output, and SYE (from my XJ). Will retain the speedo gear just in case.

Motor mounts - $220: Novak

Headers - $327: Novak/Sanderson

Radiator - $650: GRI-CU-28182-TS (Radiator and Fan, Aluminum, Crossflow, 2-Row, 22 in. Width, 19.0 in. Height, 5.313 Thickness, Single Fan) - Should fit between the lower frame CM and the stock rad support, with modification. Good to around 400HP.

Auto shifter: No idea yet. Probably a stock XJ floor shifter if I can find one.

Fuel delivery - $150: Used 255lph Walbro in tank pump (from my buddies Mustang), and 25' of 3/8 nylon fuel hose, with the cheap press fit Dorman connectors. Running a C5 regulator/filter.

I'll post links/part numbers for everything I use when I've finalised everything and am sure it's going to work.

Explanation on parts:

Motor/trans/ecu/accessories were $650. The guys seemed legit, but if not I'm not super worried. I'll spend $650 to know my Jeep is ready to drop in another SBC. The motor turned over by hand with the spark plugs removed. Heads look to be in good condition and fairly clean. Block has a lot of external rust but the little bit I can see inside without tearing it apart looks good. The guy said something about the trans controller not being correct or something, but I didn't really ask him to elaborate. I'm guessing someone bolted the wrong one on. Cheap to pull from the wrecker anyway. Hell, a whole new trans there is only $80.

I didn't want to go for an automatic, but adapting a 5.3 (never shipped with manual) is WAY more work. I could've used my AX15, but I'd have to find a flywheel, and that's a whole other can of worms as the 4.8 and 6.0's had the crank output slightly further in or out from the block (I don't remember which). In the end, I'm happy to just stick an auto on for now and if I hate it, I'll spend the time later for a manual.

I'm going to try the hybrid NP231/241c/j mainly because once done, it SHOULD be a fairly stout case and has massive aftermarket support. I was going to just use a 241c but couldn't find an SYE, or trans/case adapter that I'd be able to have at my door in less than 6 months. **** that. If I break a part, I don't wanna be out for 6 months to a year waiting on JBconversions. The hybrid 231 should be slightly stronger than a 231c (already stronger than the 231j) because of the 27spline, six pinion planetary from the 241c.

I waffled on the motor mounts and headers for a long time before ordering from Novak. I don't like that they design their products to NOT work with anything else. Ultimately though, I've never seen a 5.3 in an XJ and everyone talks about how little clearance there is between the block and the frame. Now that I have the mounts and headers and my Jeep engine pulled, I realize I could have easily fabbed up some mounts myself in an hour or so that would work with the Novak headers, or a combination of two different sanderson headers. Next swap probably won't be using Novak.

Radiator. *sigh*. The single most expensive part of this swap. I've had cooling issues for too many years and didn't want to **** around. I figure a 400hp rad should pretty much guarantee that cooling won't be the roadblock here. There is 22.125 inches from the passenger frame rail to my Dakota steering box. This cooler is supposed to be 22". I'm crossing my fingers. There is exactly 19" from the lower part of the CM to the bottom of the rad support. The CM tapers up at the frame rail, so I'll have to do some cutting to get it all in, but I think it's doable.

Shifter: Really no idea. I looked at all the conversion kits and hated them. I'm not a "stock look" weenie by any means, but the stock XJ auto shifter is probably the best option. I may change my mind when I can't find one

The Transmission to T-case adapter was for me, the 800lbs gorilla. There are heaps of ways to stick a driveline together, but ultimately it was the GM VSS that killed me. The ECU needs that 40t reluctor signal to figure out shift points on the trans. I could do some magic with the stock Chysler Speedo, but I've heard this rarely works well and you end up with buggy shift points or poor fuel economy. I wanted a GM VSS either in the t-case or on the transmission. Ultimately I could've waited 8-2000 months for JBconversions np231/241 SYE with GM compatible VSS, but I don't wanna wait. Besides which, what happens if I want to change out the case later? New VSS is what. Advance are the only guys I could find that have a trans/case adapter that puts the VSS reluctor on the transmission output (novak makes you swap your 27spl trans output for a 23spl output with a VSS reluctor, so it'll mate up to the NP231j. This is retarded. AA retains the stock 27spl output so you just need to bolt the 40t reluctor to the stock output, stick their trans/case adapter on, swap case inputs to a 27spline (way easier than swapping out a trans output), and bolt together).

Status:

I have the engine (complete except for tensioner, belt, spark plugs, intake tube/filter), transmission, 3 transfer cases and a 241c input gear (np231j 95+, np231j 94-, np231c 94-, np241 input/planetary 2000+ I think). Motor mounts and headers are installed on the motor.

Advance ****ed me and told me everything in my trans/case kit was in stock when I ordered and that it'd be here by ... two days ago. Now it won't be shipping for another week because apparently they forgot that they didn't have any of the parts in stock, and that the adapter still needed to be manufactured. ****arz. Advance was actually really decent about helping me figure out everything I needed to know about my driveline conversion. Maybe this stock issue was just an oversight and not just a sales thing.

All in all, I'm about $1950 into the swap and have most of the expensive stuff already on my bench. Perhaps I'm being overly optimistic. I still need lots of little stuff, but I really don't see this running over $5000 unless the motor is destroyed. Even then, that'd put me out less than a grand and I'd still probably be under the $5k mark.

Last edited: