- Location

- Roanoke VA

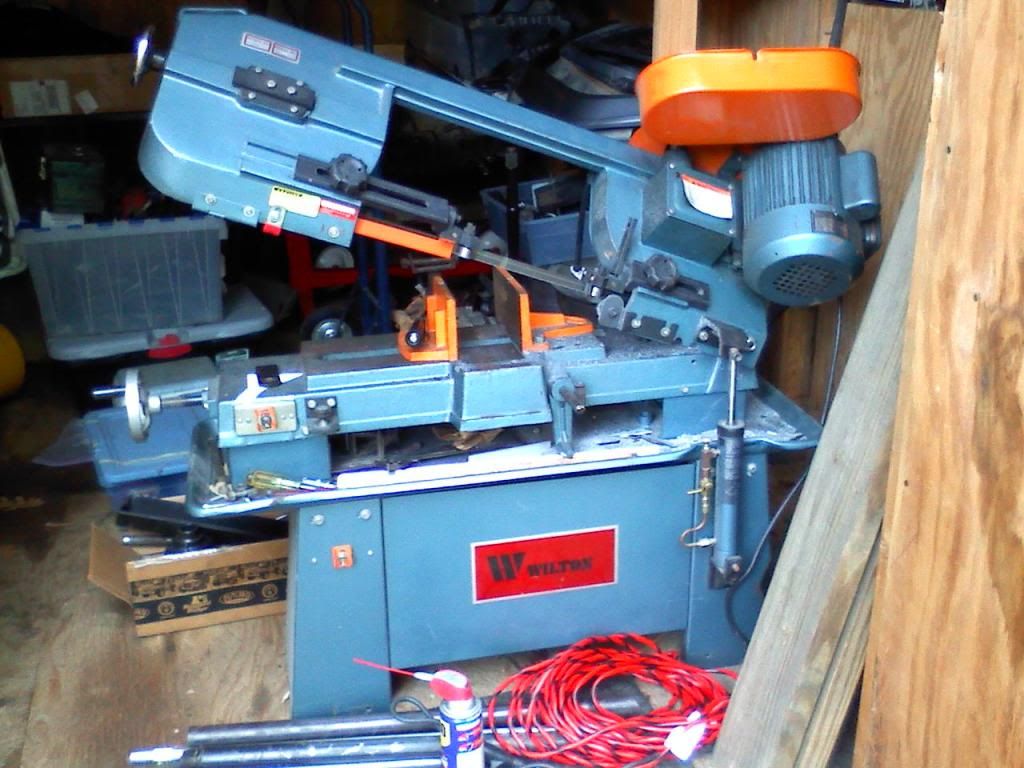

After 6 years my Wilton band saw blade snapped. I've used band saw blade welders at work (basically just a spot welder)and its easy but what about using my welder set low and tacking it back together then grinding the weld smooth.

I don't have the money for a new band right now and I have a project to do tomorrow.

Good or bad idea or "worth a try"?

I don't have the money for a new band right now and I have a project to do tomorrow.

Good or bad idea or "worth a try"?