the seal, and disk swap was not hard. there were just a few things I had to take my time on to get right, the seal was a MUST. you do have to make up your own center adjustment point for the ebrake cables, as the xj stock one is too short, and the zj one is a little funky. I combined the 2 to make a custom one for my xj. Sry no pic on that one.hasta

Bump Steer at this point was just unbearable anymore. I had shot myself in the foot on the original build. I didn't do proper research and had put a Panhard bar kit of from ruffstuff, but didn't realize that that kit was for changing the geometry of the front steering, and also would require me to go higher with my Steering TRE's. the short and simple solution. Go to OTK steering. there were 2 major company out there at the time doing 1ton OTK stuff. I chose JCR, D/T the fact that the tubes were already cut to length and threaded, I would not have to cut/weld/ and figure out my own lengths with the Ruffstuff kit. I chose Wrong....

(Quote:

Originally Posted by

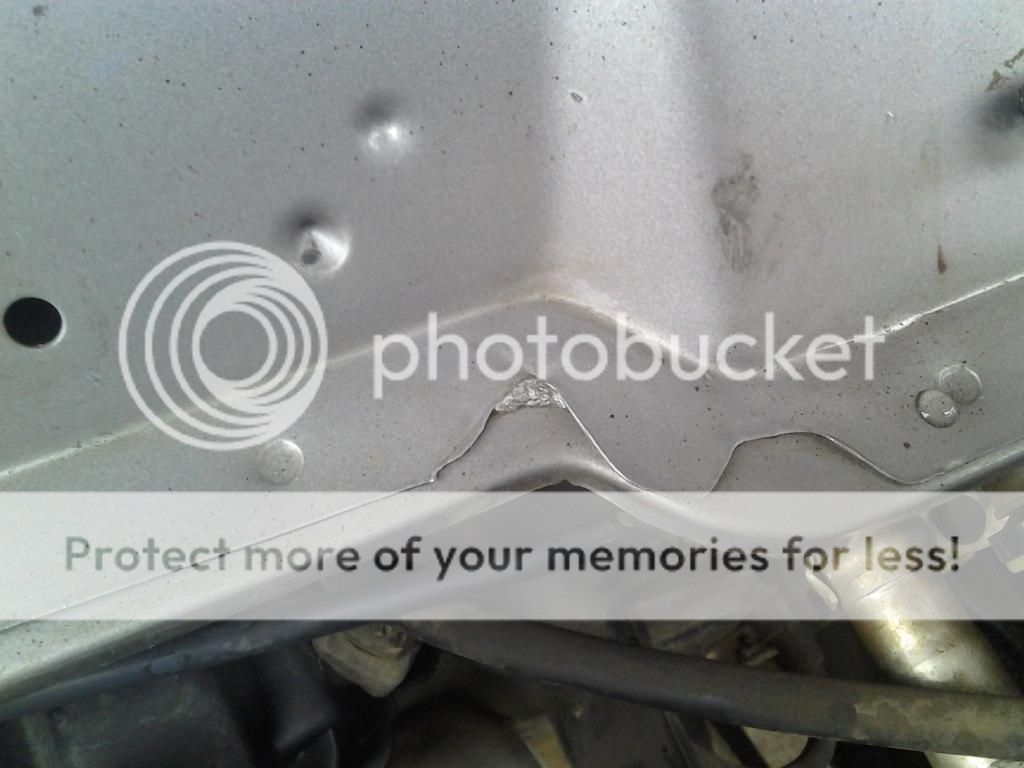

Bronzewyrm  So I installed a JCR OTK steering kit about a year ago now. sunday I went to adjust the drag link and re-grease all the tre's. I tried to lock down the jam nut on the axle side of the drag link, but it was striped. (I think I did that) At this point I needed to remove said TRE and replace the 7/8-18 LH jam nut. well after some brute force, four letter words, and a few funny looks from larry it finaly came out of the dom. The last 1/2" or so of threads on the tre were completely striped off! WTF I thought to myself... how could this be? Well the dom did not get threaded deep enough to accept the TRE. When I install everything the 1st time, I smashed a 1/2" of threads into an unthreaded tube. Then, when I took it apart, it drug all that loveliness back through the threads I did have.

So I installed a JCR OTK steering kit about a year ago now. sunday I went to adjust the drag link and re-grease all the tre's. I tried to lock down the jam nut on the axle side of the drag link, but it was striped. (I think I did that) At this point I needed to remove said TRE and replace the 7/8-18 LH jam nut. well after some brute force, four letter words, and a few funny looks from larry it finaly came out of the dom. The last 1/2" or so of threads on the tre were completely striped off! WTF I thought to myself... how could this be? Well the dom did not get threaded deep enough to accept the TRE. When I install everything the 1st time, I smashed a 1/2" of threads into an unthreaded tube. Then, when I took it apart, it drug all that loveliness back through the threads I did have.

This was a year ago and I was really fear full that jcr would tell me to E.A.D. I left a couple voicemails with no response, then dropped an e-mail. they got right back to my mail. Allen @ JCR asked that I disassemble the entire system checking each part for flaws. He said that he would then have new replacements made up and sent out to me.

understanding the situation, and that he knew this would be a problem I would not find until now. we will see tomorrow how shipping will be handled.

I know I have recommended this kit to a few members here in the NWC so I wanted to get this info up as fast as I could.

if your parts seem abnormally tight when you go to adjust them, id be real suspect...

Bronze.

Logistics on this have been crazy.

Jcr sent me a shipping invoice via e-mail. they wanted me to put the bad drag link, and tre, in a box (that I did not have) and drop it off to be shipped out (witch was hard cuz I cant drive the jeep) before they would even make up the new parts, let alone send them out. Im not sure why I needed to send back useless parts, they had the pictures. And both of us were in agreement on what had happened and what needed to be done to make it right. I need the parts and beings it was not my fault they were bad in the first place I was left with no choice but to "play ball" I dug the printer out, boxed up the stuff, borrowed grandpas truck, loaded up josh, and dropped off the stuff. Of course the address was wrong so I got to drive all over indy looking for the one FedEx drop-off in town. I also asked that a new poly spacer be thrown in the box, and that the jam nut needed to be there as well. He said he talked to the steering guy, and that they would be made up and shipped out 1st thing in the morning. This was last Thursday April 3. keep in mind I found this Sunday march 30th. So I got a tracking number the next day and it said arrival date April 10th. DAMN! I got to wait another WEEK! omg, ok, I have a bunch of stuff to do to the jeep. I now have the "down time" to do some of it... :explosion and say what you want, JCR is standing behind there stuff and sending new stuff out.

Well I woke up to another e-mail from jcr today.(April 8th) @days before I was to receive my replacement parts. By this time there are 13 messages back and forth about these issues. They say that they got my stuff back, opened the box, and realized there was a problem. They made up a Tie Rod, not a Drag Link, and had sent that out to me... When he opened my return box he knew there was a problem and got a hold of me the same morning. His response to the problem was to sent out the rest of the kit, the pieces that he had not sent out already making it a full bran new kit. I asked him if he could send out the parts next day air, or at least priority this time, beings I had already been waiting 2 weeks with no steering in my jeep. I have not received a tracking number for the second shipment as of yet, nor a response about upgrading the shipping.

Im VERY disappointed in my decision to buy this kit from JCR after all this. I have done loads of business with Ruffstuff. there steering kit is almost the same. the difference being that you have to measure your own tubes, and burn in tube adapters. the price is the same. I went with this JCR for ease of install. Keep in mind jcr does not offer tapered adapters for the tre's, only the reamer, so I was making a order with ruffstuff anyways. I had a similar problem with some heim joints on my ruffstuff order. In one e-mail to dan @ ruffstuff. they had pulled my original order, looked up my parts, looked into my description of the problem, pulled new parts, packaged them up, and had them sent out free of charge and was sending me a reply to let me know all of this and give me a tracking number. 2 days later I had my parts. With no mention of the old/bad parts, or what to do with them. I don't know why its taken 15 emails, 15 days, 3 shipments, and 10 pictures to get the parts I need. I don't know why I needed to send the parts back. I sent pictures, we agreed that it was a manufacturer fault and that I would not have found it until now. There paper weights now right? I don't know why you got the parts from me 2 DAYS before I got the 1st shipment from them. And im not sure why there is not a little more urgency on there part. They have competition!

My jeep is sitting out back, with nothing under it for steering, has been for 2 weeks, and im still not sure when im getting the right replacement parts to fix it. NONE of this being my fault, or that I could have done something to prevent it from happening. JCR

IS getting this taken care of, But Supper slow, and with very poor communication. I Now have a bad taste in my mouth. And I also regret all those recommendations I have made to all of the people , Boasting the JCR stuff.

I just hope the parts get here soon. I Want to go wheeling, shopping, and maby some other things that normal people do. (normal being With Car)

Rant over! That's where I AM with JCR. looking forward to being done with this none since.

Bronze. )

Once that was all over, I had a fully functional no bumpsteer front steering setup. plus no more worries about blown TRE's

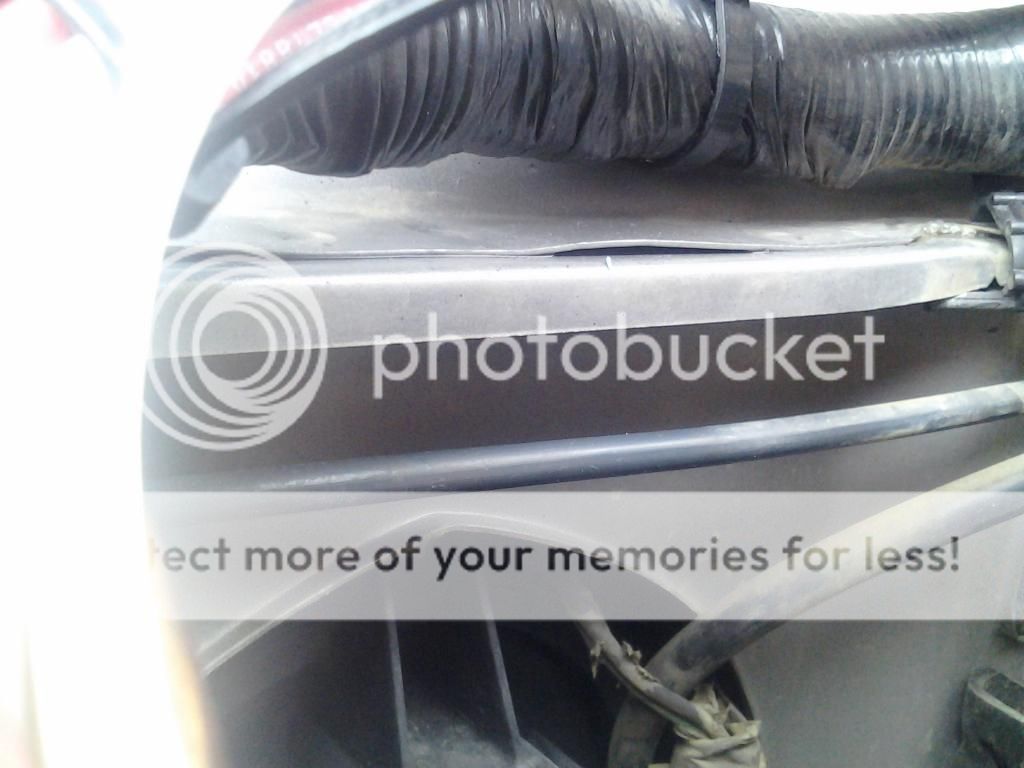

When you got OTK, you have to cut the sway bar mounts off of the axle. hence No Sway bar. This proved to be sketch while pulling my Sleeper up windey roads. so after a while I broke down and bought the stupid JCR front sway bar relocaters. They suck, I hate them, and yeah, they suck.....

I was feeing really good about my jeep now. Feeling like my OVER BUILT status was doing good, DD's was going well. It was time to wheel her a bit again. This proved to be the beginning of the end for a while. I set off a chain of BS that took me a couple months to get past. My battery went dead... I needed the winch for just a few pulls at the farm. (dodge recovery) so I grabbed a spare battery and headed out. I made the pulls fine, got out of the field where the jeep died via charge loss. I pushed the battery (and alternator) to the pint of the fuel injection cutting out on me b4 it died. I slapped the new battery in it an drove home not thinking anything of it. Weeeeeeeeeelllll That was a little much it turns out for the jeep. I fried the alternator, battery, and my electronics inside the jeep all started to act up... I was about to freek! I went through 2 bad batteries at the parts store b4 they gave me a good one(this did not help diagnosis at all) I replaced ALL of my alternator wireing Via 5-90's posts, then did some research about the upgrade to alternators. It turns out the zj 145A and the Durango 160A alternator have the same size case and bolt pattern, the Durango runs a 7slot pulley, the zj/xj run a 6 slot. I decided to go with the Durango 160A flavor. As I run Bumps with my winch from time to time...

I needed to adjust the drag link some time later, this is when I found the problems with the steering system. (above) so while I waited for that mess to get sorted out I decided to dive into a couple other things I had been meaning to do for a year or more...

Parked her for another round!...!...!...!

This time it was going to be Upgrades! YEAY!

and came up with a theory and plan.

and came up with a theory and plan.

for the support:loveu:

for the support:loveu: