- Location

- Hammertown, USA

So.. We hitched a ride back to camp on the Crane of Shame.

Last edited:

Everything I have seen for the Taurus fan is 2800 CFM.

But every site seems to list different numbers for it, too.

Whatever we do it probably won't be a single fan.

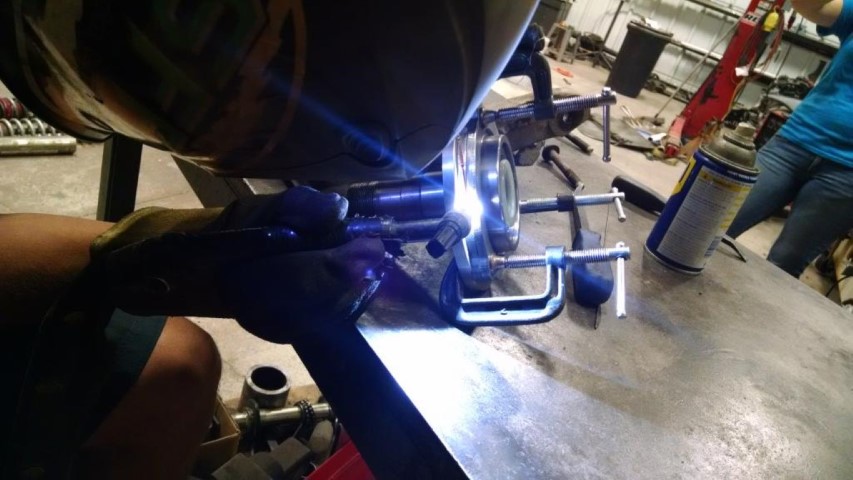

You could stake/Loctite the bearing in or even break out an aluminum welder and weld on some bosses for screws and screw on a retaining plate.We still had to deal with the failing fan clutch. I didn't take any photos, but we drilled it out and thru-bolted it similar to what I did with our previous one last year. Re-assembled the car and while we missed qualifying, started the race at the back of the pack.

We were running fast and strong, and up to third place in class just a couple of laps in while fighting heavy traffic. Making a pass on the back strait away we revved the hell out of the motor (6000+) and then went into a hard corner. After the corner the car started to get warm fast, and then we lost power steering and charging.

Got out of the car and popped the hood. I dont have any photos (no camera in the fire suit) but our fan pulley was misaligned and the belt popped off of and was loose. With great difficulty we got it back on, fired the motor and but came right back off again. There was really nothing we could do with no tools or parts and only 45 minutes left in the race, so we sat back and enjoyed a great view of the race from mid field.

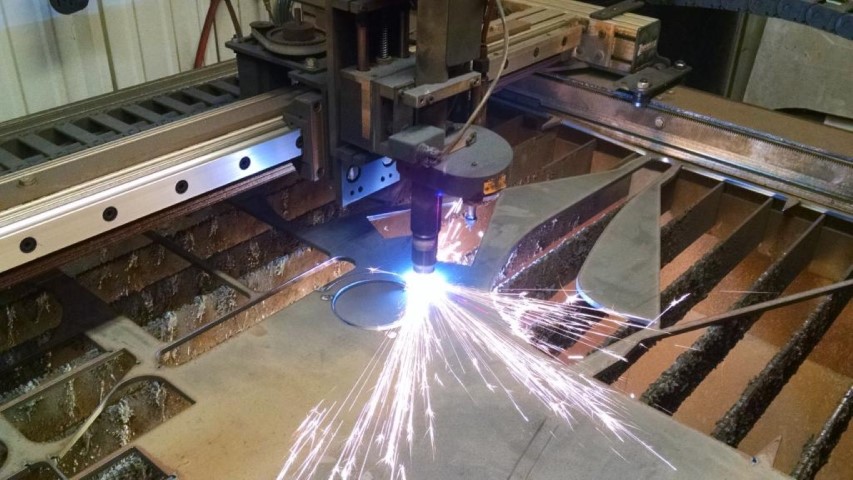

After the event was done got towed into camp. I didnt think to take any photos before the guys tore into the car, but here is what they eventually found:

On our high RPM runs down the back strait, the fan with no clutch had so much force that it pulled the bearings out of the housing. If the belt hadnt jumped, it probably would have put the fan into the radiator shortly.

I think it would be easier, cheaper and more reliable to stick with mechanical and mitigate the possible issues.Everything I have seen for the Taurus fan is 2800 CFM.

But every site seems to list different numbers for it, too.

Whatever we do it probably won't be a single fan.