- Location

- sacramento

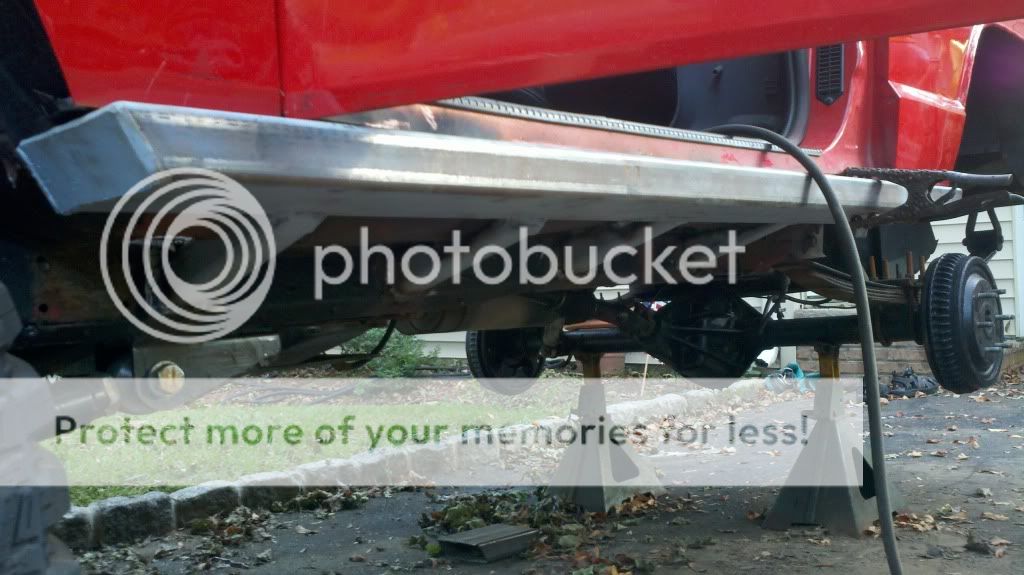

i put in .095 wall 2x6 rockers last january and have beat it pretty hard, coming down hard on it, on a bunch of trails including the con a few times this last summer. i figure when it starts to get crappy ill weld up some 3/16 2x2 angle on the outside...