Re: Project Scope Creep: Educate me on R&Ring an ARB locker in a D30

Thank you Dan for those setup bearings and for the shims too. I did not realize it, but the parts kit I got only came with pinion shims. Your carrier shims were a huge help today.

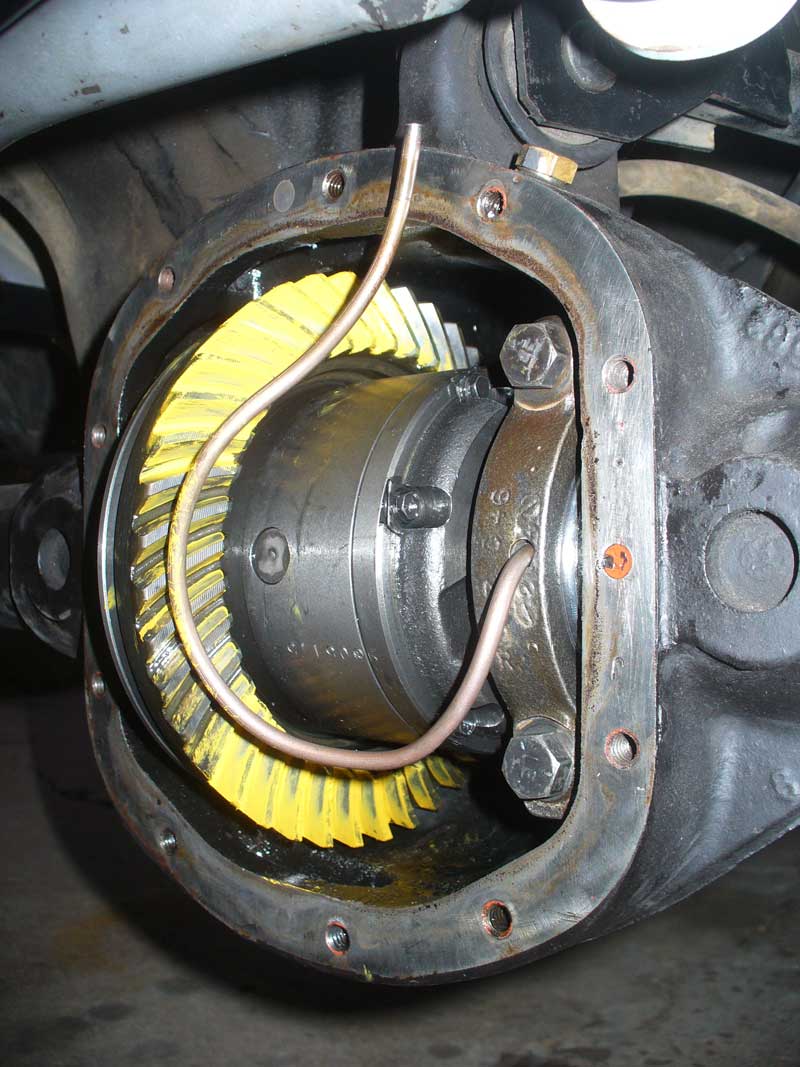

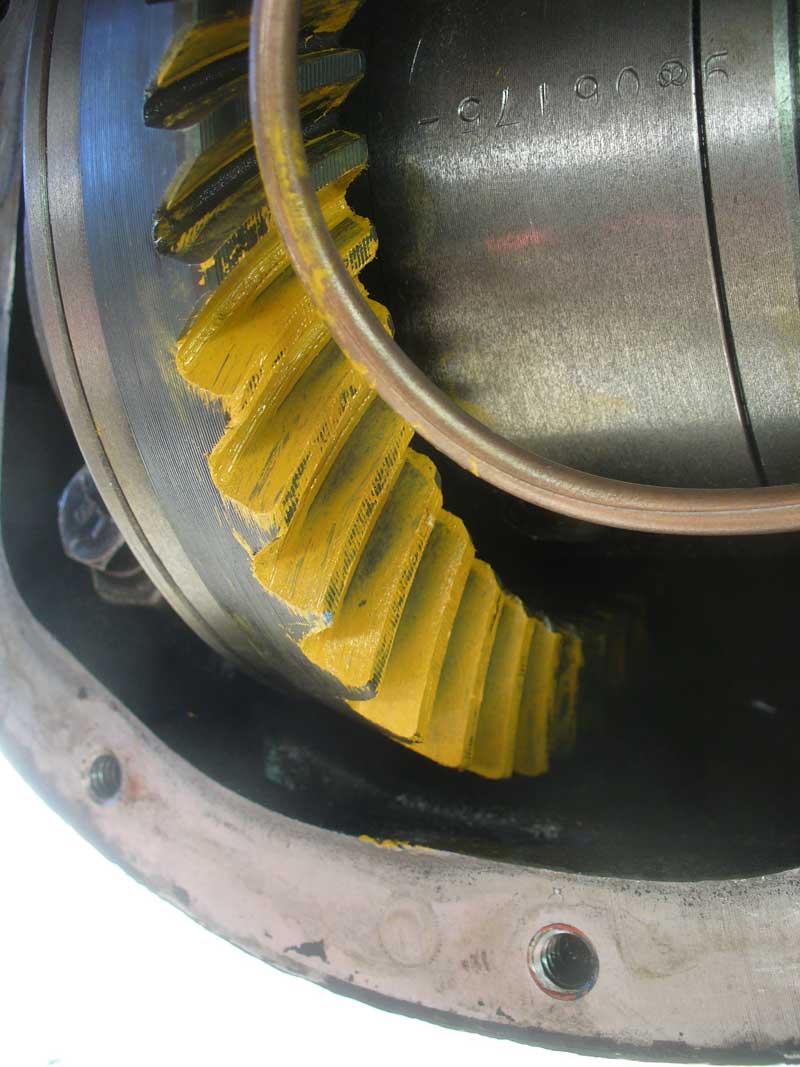

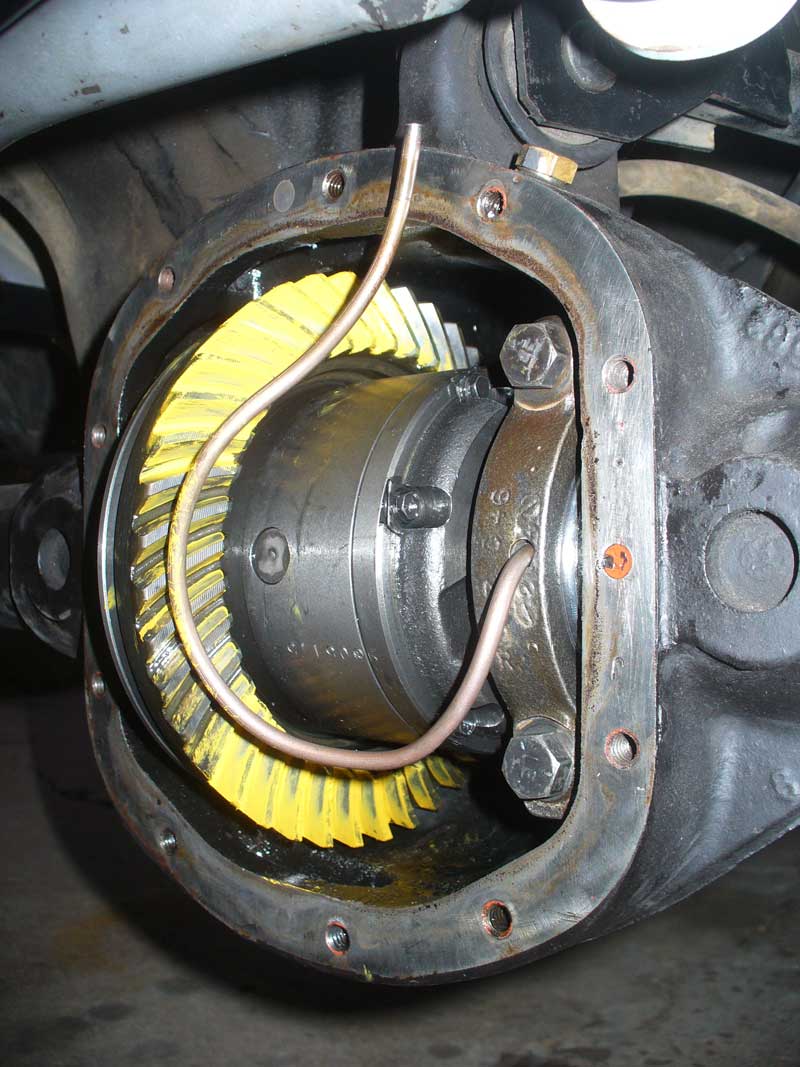

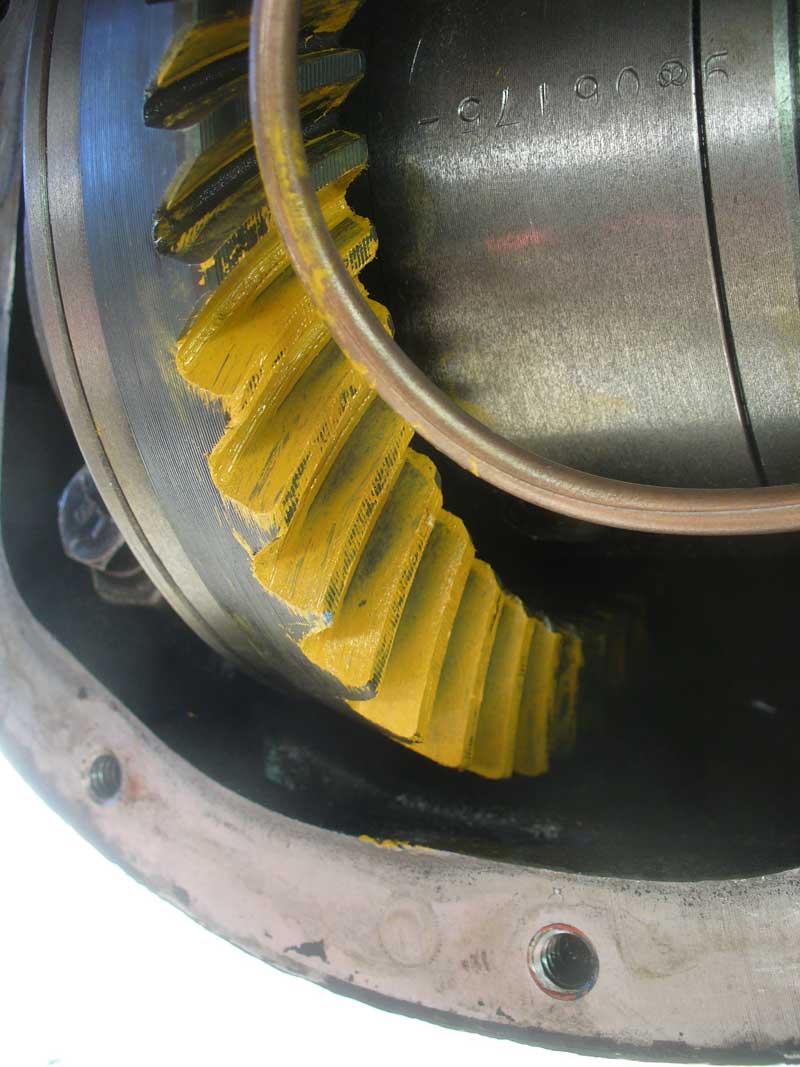

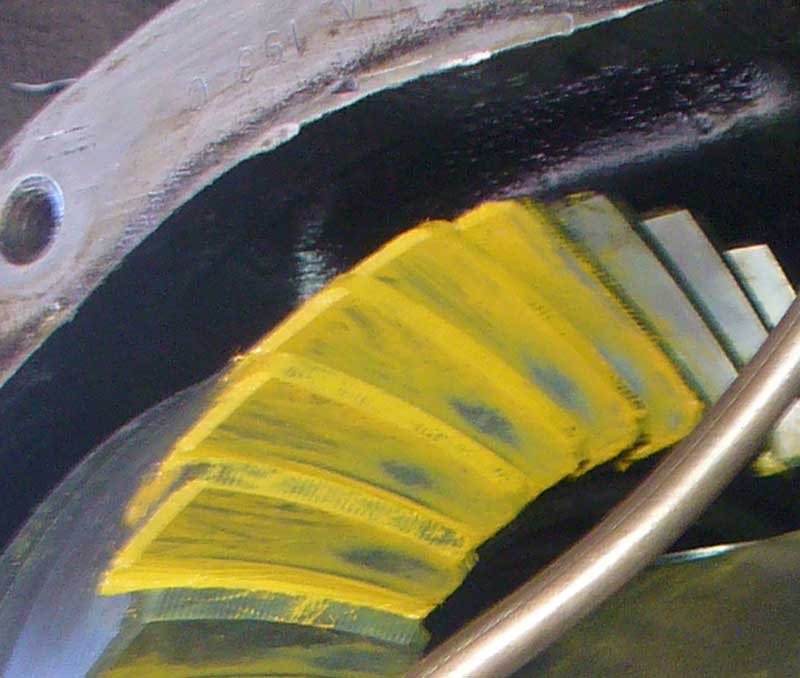

I think I had the carrier in and out about six times today. It took me forever to finally get the backlash right, but I did manage to get a range of 0.002" to 0.005". At that point I tried running a pattern. I am using a pry bar for resistance, and not getting the pressure I need on one side, but these two pictures are my first run:

One (not really sure how to interpret):

Two (Fairly clear pattern):

It looks to be pretty much towards the toe on the one side, and I really don't know what to make of the other side. From what I could tell from the FSM if both sides are toward the toe then increase backlash. Not what I wanted, but I tried it and no, that is not the answer:

Still pretty much towards the toe. So I figure I need to move the pinion. I think in towards the ring gear (add to the shim stack on the inside bearing race). At that point I was out of daylight and out of energy.

I also found there are far more "acceptable" patterns than what is in the FSM. This page leaves me scratching my head:

https://www.ringpinion.com/Content/Book/Reading-and-Adjusting-Ring-and-Pinion-Tooth-Patterns.pdf

Given that I am dealing with a used gear set was my first pattern good enough? Should I go back to that shim pack and leave the pinion be?