Ok so update time boys and girls haha.

Got my free front end into my garage today. yeaaa another Dana30 but hey, I'm going to fix most the week links and like I've said the whole thread I don't need tons and 40's. This is a rig that she can learn to wheel in but still build up when needed when the time comes.

So, some of the things I will be doing to the d30 Ballistic fab Xj coil brackets, my own upper mount, an internal sleeve, and I'll also truss the ears of the inner c's to stop them from bending. I think I might make my own front diff for this axle as well not to sure on that one yet however.

The inner truss I'm talking about is alot like this kit

http://www.rockslideengineering.com/servlet/the-9/R-dsh-SE-Inner-Axle-Housing/Detail

Doing mine much similar using DOM tube but instead of that odd shapped 2inch thick chunk O' steel I'll be using 3/16's plate.

Ok pic time...

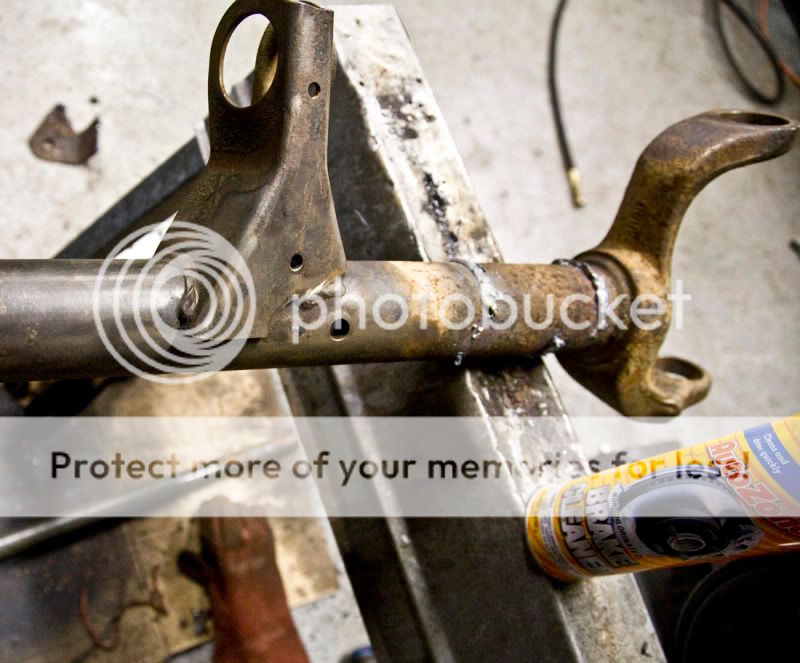

This is the victim 95 Hp d30 no disco... nothing special

As you can see these brackets are cooked.. seen much better days and nothing I wanted to repair.

and the control arm monstrosity haha

well for free I didn't mind this. So first thing is I stripped it down right away...

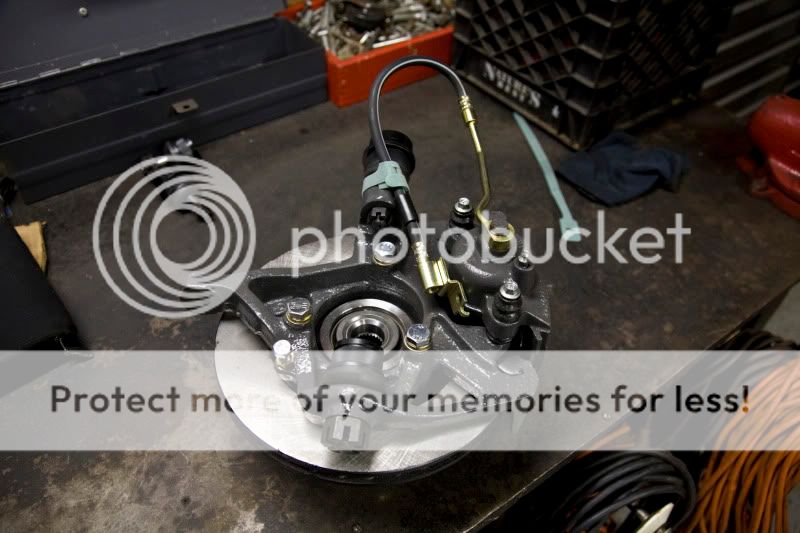

I'll be running another Aussie locker up front here as well.

Next was to cut the old buckets and all the mounts off and toss those.

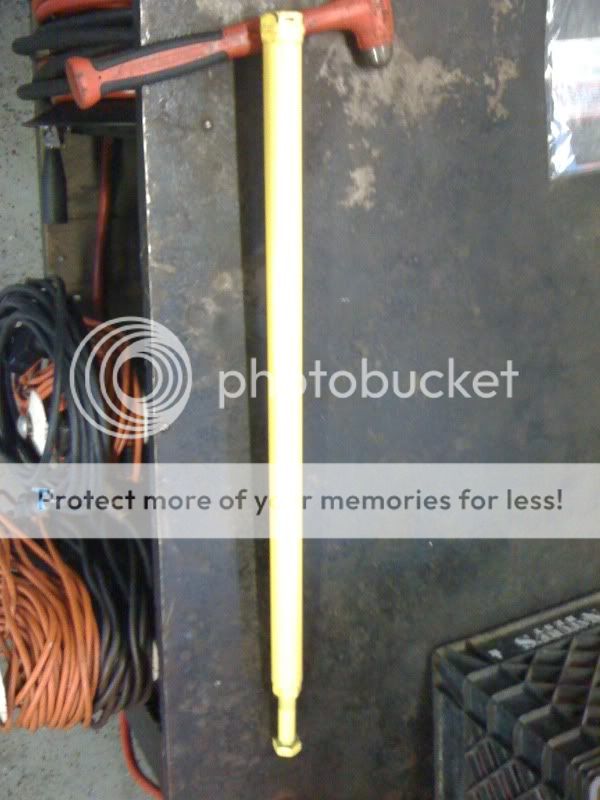

And a pic of the inner truss idea I'm doing. (don't mind the nasty rusted tube just for a visual.)

And started the last side of my rear axle truss..

I just hate using a hole saw ughhhh

While I'm on this, anyone know the OEM degrees for the stock coil brackets? Mine are all tweaked so I can't really trust them. And I can't seem to find it in my notes...