-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project FSJ diesel

- Thread starter altrocker1

- Start date

- Location

- Rainy side of Washington

Real jealous, and subscribed. I need ideas and pics of what the one I'm getting is supposed to look like.

altrocker1

NAXJA Forum User

- Location

- Iowa

too many days have gone by...been out on shows and doing some memorial day holiday stuff. got back at it today. went and got my wheels...if anyone needs a set of ok tires, they are for sale. they are adventruo mt's in okay shape. i would say they are 40% or less...they are 285 75 16... the wheels are going to get sandblasted and repainted.

started to grind and sandblast the frame. bought some coal slag and a cheap blaster from harbor freight...it doesn't work great, but it gets the job done. plus i can use it for other projects down the road. it took a bit to get the method down, but i got a little better. i used a wire wheel and flap disc to get the nasty stuff off then the blaster to get down to bare metal. not too speedy, but this is where i got in two hours tonight...

you can see where the difference between dirty rusty nasty, ground down and sand blasted bare. its probably going to take a good 8-10 hours to strip it but so far the metal looks pretty darn good. now i just have to figure out how to get inside the boxed parts of the frame. the coal slag is messy as hell, but its cheeeeap. 7 bucks for a 50 lb bag...so far i use about 1/3 of the bag so at that rate it will take about 3-4 bags of that stuff. i have a feeling the driveway at the shop is going to be black for a while. i think next time i might put a tarp down to try to save some of it. fortunately i bought a blasting hood...it would have been a horrible nasty mess in my hair. i have the opposite of wheeler hair unfortunately i wasn't wearing the hood when i was doing the grinding. now it tastes like metal when i breathe...oh well at least i got my daily intake of iron

unfortunately i wasn't wearing the hood when i was doing the grinding. now it tastes like metal when i breathe...oh well at least i got my daily intake of iron

started to grind and sandblast the frame. bought some coal slag and a cheap blaster from harbor freight...it doesn't work great, but it gets the job done. plus i can use it for other projects down the road. it took a bit to get the method down, but i got a little better. i used a wire wheel and flap disc to get the nasty stuff off then the blaster to get down to bare metal. not too speedy, but this is where i got in two hours tonight...

you can see where the difference between dirty rusty nasty, ground down and sand blasted bare. its probably going to take a good 8-10 hours to strip it but so far the metal looks pretty darn good. now i just have to figure out how to get inside the boxed parts of the frame. the coal slag is messy as hell, but its cheeeeap. 7 bucks for a 50 lb bag...so far i use about 1/3 of the bag so at that rate it will take about 3-4 bags of that stuff. i have a feeling the driveway at the shop is going to be black for a while. i think next time i might put a tarp down to try to save some of it. fortunately i bought a blasting hood...it would have been a horrible nasty mess in my hair. i have the opposite of wheeler hair

Last edited:

altrocker1

NAXJA Forum User

- Location

- Iowa

on a side note, i made a dumbass move tonight. i have 2 outlets on my air compressor and i almost always use the one side...today i decided to use the other side and it didn't seat right. i was standing in front of the compressor when the hose let loose and whacked the connector right on my shin bone...hit the bone in that annoying spot that always hurts.

i also just pulled a piece of wire wheel that was embedded about 1/4" into my leg that i didn't know was there until it caught on something. i need some chaps to wear when i work... preferably assless...anyone wanna loan me some?

i also just pulled a piece of wire wheel that was embedded about 1/4" into my leg that i didn't know was there until it caught on something. i need some chaps to wear when i work... preferably assless...anyone wanna loan me some?

XJosh95

NAXJA Forum User

- Location

- Green Bay, WI

And he wears them backwards when he does that.

Rev Den

NAXJA Forum User

- Location

- Plainfield, IL

I have a place wear I buy mine....but I am not gonna share it here.

Rev

Rev

- Location

- Michigan

I have a place wear I buy mine....but I am not gonna share it here.

Rev

Assless bibs?

VAhasnoWAVES

NAXJA Forum User

- Location

- Lake City, Mi

coming to Mi anytime soon? i could use those tires...

the chilly peppers are playing at the joe louise tonight, why arent you doing that show?

the chilly peppers are playing at the joe louise tonight, why arent you doing that show?

altrocker1

NAXJA Forum User

- Location

- Iowa

coming to Mi anytime soon? i could use those tires...

the chilly peppers are playing at the joe louise tonight, why arent you doing that show?

dang it...i should have broth the tire with me! im coming to mi now on my way back through next week (although technically i went to mi for about 5 minutes by accident on my way here). im stopping in erie on my way home and possibly ann arbor, but that is still up in the air. i will be towing my diesel motor home on my way back...i was really hoping to have the frame done by the time i got the motor back, but oh well. progress slowed to a halt (though i have done a bit more since the last update) when i hit june. i will have some time in july to work and a bunch of time in august. my hope it to have a cab on and things wired, fitted and rolling by the end of august. i may also be picking up new bedsides on my way back through ohio if i can make a little more money while im here

altrocker1

NAXJA Forum User

- Location

- Iowa

i also may have found a full rhino/gladiator clip, lights and grille so standby for that. the deal on the boobie grille fell through. i just cant seem to find one

XJosh95

NAXJA Forum User

- Location

- Green Bay, WI

I prefer the gladiator grille.

altrocker1

NAXJA Forum User

- Location

- Iowa

this just in...pennsylvania sucks with 31's and stock gears pulling a trailer with a 700lb motor, tranny and transfercase. on one of my many breaks...

ooh...what is that i spy

home safe and sound...ready to rock and roll. i have a lot of free time in august so i know exactly what i'll be doing!

ooh...what is that i spy

home safe and sound...ready to rock and roll. i have a lot of free time in august so i know exactly what i'll be doing!

altrocker1

NAXJA Forum User

- Location

- Iowa

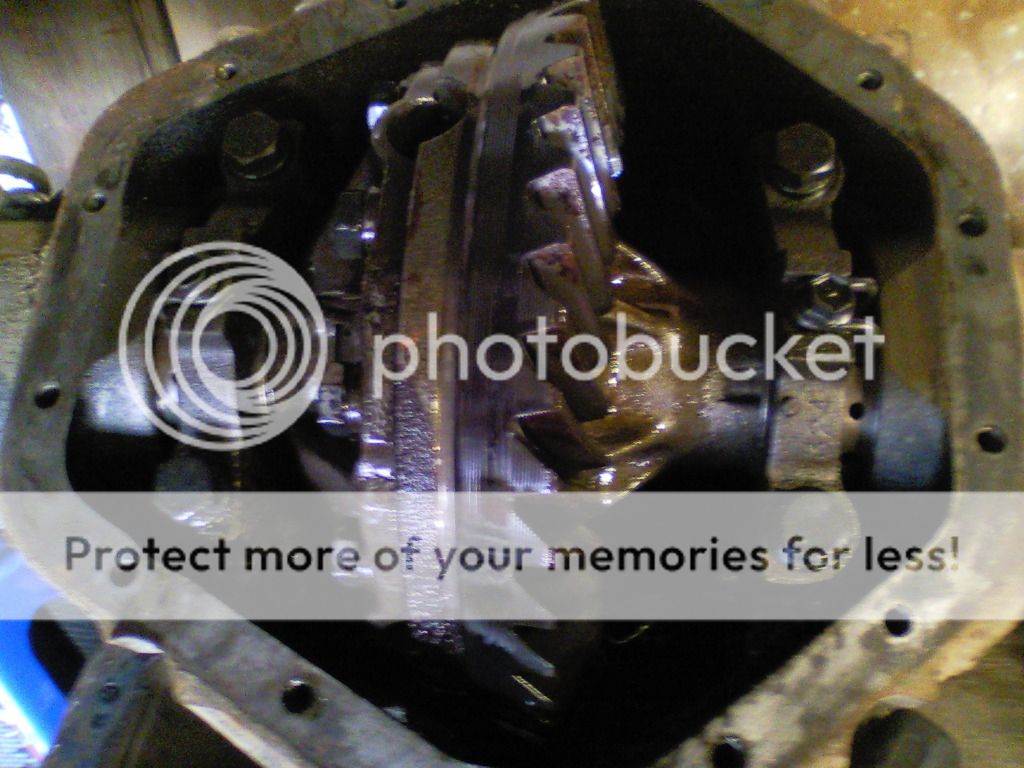

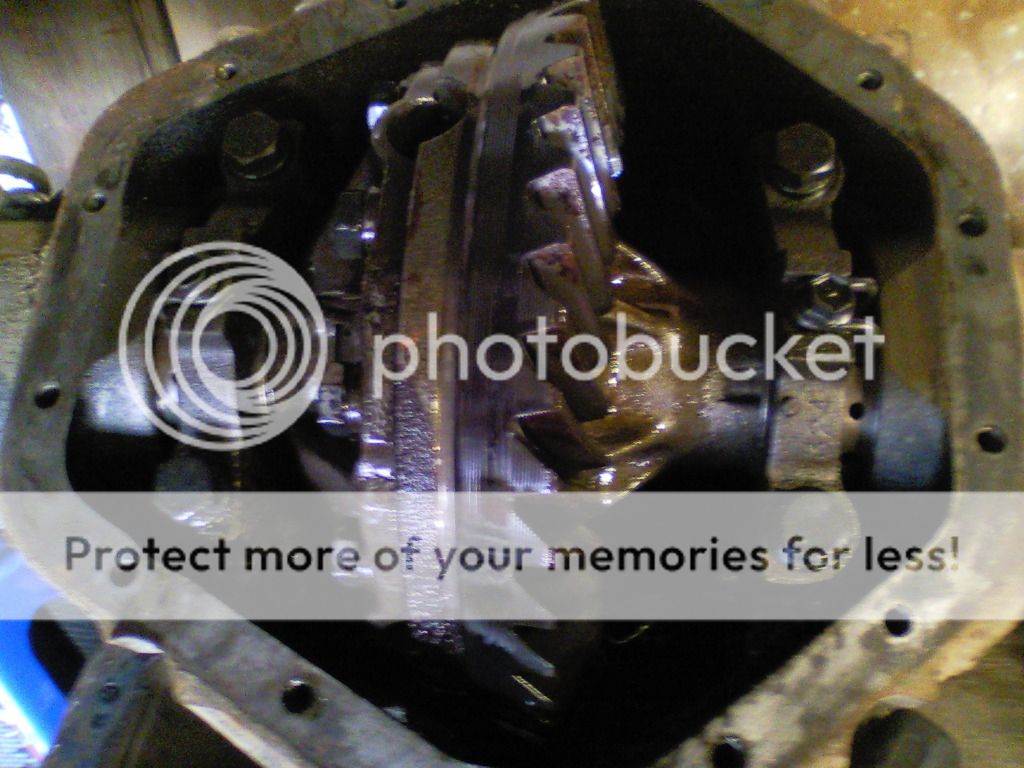

started to clean and organize the shop before things get really hot and heavy. i put the dana 60 i got for free up on the bench and i knew it might be in rough shape since there were no shafts in it, but it was worse that i expected. the carrier was locked solid with rust and there was a mouse nest of some sort in there...also it was not a limited slip like the guy thought.

i couldn't get the carrier to budge at all so im going to give up on it. i have the 14 bolt that is the right gearing and the disc brake conversion on the 14 bolt is cheaper...so at this point it might be the cheapest route to go. so if anyone wants a dana 60 ya'll can come get it. if not its on the way to the scrapper.

the knuckles on the 44 are a little frozen, but the carrier turns well and the gears look pretty good.

14 bolt looks great on the inside

the workbench was saggin a bit with all the weight, so you'll notice my sweet 2x4 rig up to keep it level while im working on my axles

got the motor, tranny and transfer case separated and stowed away in the shop while i finish the frame.

they won't be stowing there for long fortunately. the cab is getting new floors as we speak so it will all start to come together very soon

i couldn't get the carrier to budge at all so im going to give up on it. i have the 14 bolt that is the right gearing and the disc brake conversion on the 14 bolt is cheaper...so at this point it might be the cheapest route to go. so if anyone wants a dana 60 ya'll can come get it. if not its on the way to the scrapper.

the knuckles on the 44 are a little frozen, but the carrier turns well and the gears look pretty good.

14 bolt looks great on the inside

the workbench was saggin a bit with all the weight, so you'll notice my sweet 2x4 rig up to keep it level while im working on my axles

got the motor, tranny and transfer case separated and stowed away in the shop while i finish the frame.

they won't be stowing there for long fortunately. the cab is getting new floors as we speak so it will all start to come together very soon

- Location

- Rainy side of Washington

I spy some definite rust on the 14bolt ring gear... should probably use a brass wire wheel and knock some of that off. Certainly not an angle grinder or anything that'd mar the surface of course.

altrocker1

NAXJA Forum User

- Location

- Iowa

no...it does have a very small bit of surface rust on the section that wasn't submerged in gear lube. it should come off easy. i don't even think it would take a grinder to get it off. its very light

altrocker1

NAXJA Forum User

- Location

- Iowa

i think the floorboards had some rot

altrocker1

NAXJA Forum User

- Location

- Iowa

decided to finally get the dang box off...i was actually surprised how high my ol shop crane actually went. then collin helped me lift the front off.

all bare...no holes in the back for the most part, but its definitely crusty in spots.

got the old motor mounts cut off/unbolted and ready for the new custom mounts...

also got the front axle out from under the frame so i could prop it up high to make grinding the bottom easier.

got the front half of the frame mostly cleaned, but i still need to blast the pitted parts and some of the nooks and crannies.

i also had a flap wheel grenade itself today...it was a little scary. i think it got stuck in a groove and ripped the chunk off the flapwheel. it was strong enough to yank the whole grinder out of my hands onto the ground. a little scary, but fortunately i jumped out of the way in time

all bare...no holes in the back for the most part, but its definitely crusty in spots.

got the old motor mounts cut off/unbolted and ready for the new custom mounts...

also got the front axle out from under the frame so i could prop it up high to make grinding the bottom easier.

got the front half of the frame mostly cleaned, but i still need to blast the pitted parts and some of the nooks and crannies.

i also had a flap wheel grenade itself today...it was a little scary. i think it got stuck in a groove and ripped the chunk off the flapwheel. it was strong enough to yank the whole grinder out of my hands onto the ground. a little scary, but fortunately i jumped out of the way in time

Last edited:

altrocker1

NAXJA Forum User

- Location

- Iowa

well...as far as i can tell, huntin season is over for me...so its shop time! first step is to get the j10 mobile so i can push and pull it in and out of the shop. i test fit the front axle under the front leafs and she fits like a gem...

however...i did decide that i didn't want to deal with the rust on the dang rims that i have (getting darn sick of rust) so i sold the rims and tires in hope of finding something better. i also picked up a second set of axles (14b and d44) to swipe some of the good parts on the 44 for spares...then i promptly sold the 14b for $25 less than i paid for both axles

today started what will be a longer project to get the 14 bolt mounted under the frame and to fix the rust holes in the back side of the frame. i started with the rust...yuck.

after i whacked the old perches off, here was what i was left with

these are the worst two holes, the one on the other side isn't really bad at all. i bought a piece of 3/16 flat steel, drilled a few holes in it and welded around the perimeter, through the holes in the steel and through the holes in the frame

this is the first big project im tackling with my welder...up until now, i have been welding with flux core but i gave solid wire a try. took me a bit to get the hang of the speed and feel of it, but it didn't take me long to realize that my regulator was broken...thus i lost most of my gas too quickly and ran out :flamemad: so back to flux core i went for the 2nd side. actually it came out much better than the first side...mostly because i started to settle into a good groove about 2/3 of the way through the first side. all in all, its not pretty but it did get WAY better on side 2. i have to go buy some more wire tomorrow but ill snap a pic of the welds when im done. im kinda proud of them. i am NOT proud of my first welds...they started off looking like this

aaah well...no one will ever see it. and in all actuality...its on there REAL good

i also took some time to play with my welder and gas bottle on some sheet metal and i'll be damned if my sheet metal welds didn't look better than my welds on the frame. im not quite there, but a few more weeks/months of practice and i think i can get her figured out

tomorrow i'll finish plating up the other side and then move to mounting the new spring hangers...(i may bring in a friend to give me some help with the spring hanger welding). i also need to find 2 more 8 bolt rims with tires...

however...i did decide that i didn't want to deal with the rust on the dang rims that i have (getting darn sick of rust) so i sold the rims and tires in hope of finding something better. i also picked up a second set of axles (14b and d44) to swipe some of the good parts on the 44 for spares...then i promptly sold the 14b for $25 less than i paid for both axles

today started what will be a longer project to get the 14 bolt mounted under the frame and to fix the rust holes in the back side of the frame. i started with the rust...yuck.

after i whacked the old perches off, here was what i was left with

these are the worst two holes, the one on the other side isn't really bad at all. i bought a piece of 3/16 flat steel, drilled a few holes in it and welded around the perimeter, through the holes in the steel and through the holes in the frame

this is the first big project im tackling with my welder...up until now, i have been welding with flux core but i gave solid wire a try. took me a bit to get the hang of the speed and feel of it, but it didn't take me long to realize that my regulator was broken...thus i lost most of my gas too quickly and ran out :flamemad: so back to flux core i went for the 2nd side. actually it came out much better than the first side...mostly because i started to settle into a good groove about 2/3 of the way through the first side. all in all, its not pretty but it did get WAY better on side 2. i have to go buy some more wire tomorrow but ill snap a pic of the welds when im done. im kinda proud of them. i am NOT proud of my first welds...they started off looking like this

aaah well...no one will ever see it. and in all actuality...its on there REAL good

i also took some time to play with my welder and gas bottle on some sheet metal and i'll be damned if my sheet metal welds didn't look better than my welds on the frame. im not quite there, but a few more weeks/months of practice and i think i can get her figured out

tomorrow i'll finish plating up the other side and then move to mounting the new spring hangers...(i may bring in a friend to give me some help with the spring hanger welding). i also need to find 2 more 8 bolt rims with tires...

altrocker1

NAXJA Forum User

- Location

- Iowa

well...i think im gettin better. a few more weeks of doing this and it might start to feel comfortable.

2nd side turned out way better than the first

2nd side turned out way better than the first

Similar threads

- Replies

- 4

- Views

- 103

- Replies

- 9

- Views

- 213

- Replies

- 7

- Views

- 387