Talyn

NAXJA Forum User

- Location

- Radford, Communistwealth of Virginia

I think I have officially lost my mind.

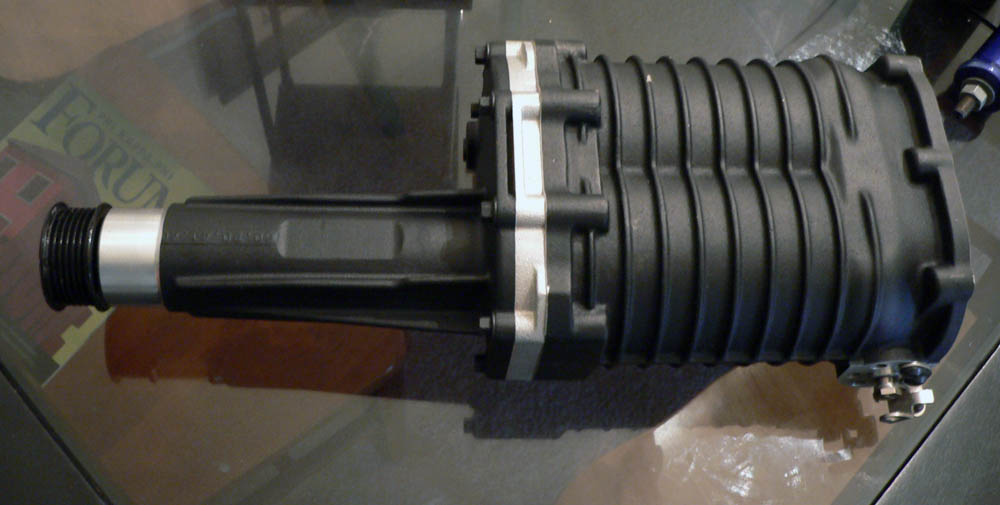

About a year ago I've looked for a Magnuson MP90 supercharger on ebay with no success. I put the thought aside but saved the search, which I had forgot about. A little over a week ago ebay sent me an email with a single match. An MP90 in near perfect condition. So, I bid and I won. Funny thing is that a day after the auction ended another on came up exactly the same. It sold for a little less, oh well.

I don't know what it came off of, but the seller stated "It looks to have been re manufactured and never installed". I received it today and it is in like new condition. It looks to have been bolted on to something, but it has no signs of actual use. The rotor's Teflon coating is untouched, no nicks in the rotor tips and no scores in the case. Basically a new supercharger.

This is a 4th Generation MP90. It differs from the 3rd generation M90 in a few ways. It's total height is slightly lower (5.30" vs 5.42"), it has an internal bypass valve, the outlet and inlet are different (inlet can accommodate a TB w/ an adapter plate), and it is said to be more efficient. The bypass actuator can also be positioned on either side in any number of positions.

This isn't something that hasn't been done before. I got the idea from Think!Performance's kit. http://www.4wheeloffroad.com/techarticles/engine/131_0803_40l_jeep_xj_cherokee_supercharger_kit/

Also, I later found that Montelibre on JeepStrokers installed one on his stroker:

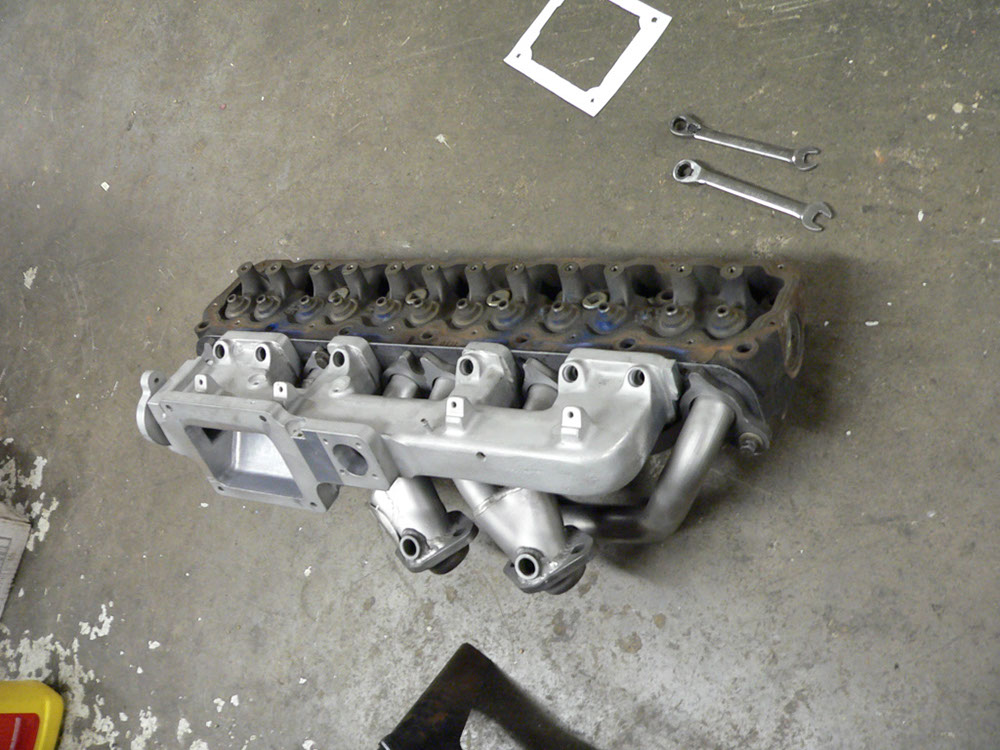

Think! had a plate bolted to a slightly modified 99+ intake manifold, with some cut outs for the passenger side SC bolts. Montelibre also had a plate bolted to the intake manifold using a bit less modified manifold than Think! but he also made a plate to go between the SC and manifold, making bolting it on a bit easier.

For mounting it my plan is to cut the manifold top off as much as possible with and angle cut toward the driver side. Then weld 1/2" aluminum plate over it. The angle cut is to drop the snout as much as possible to prevent any interference with the hood. Then make an adapter plate (like Montelibre) to bolt to the bottom of the MP 90, which would then bolt to the modified manifold. The manifold will be coated in a heat barrier coating and I will also use a form of adhesive heat wrap, which I am already using on the manifold I have now. I am also planning on borrowing Montelibre's snout support/pulley plate idea, which would support the snout better and give more belt wrap on both the MP90 pulley and steering pump. I am unsure how to attach it to the snout yet, but looking for a good solution. The power steering pump will obviously have to be modified with a remote reservoir and possibly a different high pressure fitting. I am not 100% sure what to do about the pump, but I will cross that road when I get to it. I will obviously have to lose the Volant air tube, but plan on keeping the air box and Amsoil air filter.

The back of the MP90 will get a plate which will house the various vacuum lines and the throttle body. I plan on designing it to fit a 68-70mm throttle body in the future. Also, I plan on drilling and tapping it for water/methanol injection nozzles, which may come later.

For fuel I plan on using the AEM FIC6 with larger injectors. Size is undecided as of now.

This will be going on my 4.6L stroker. It has a static compression ratio of 9.54:1 and a dynamic compression or ratio of 8:1. Because of this I will be shooting for a boost of 4-6psi. I plan on using a 2.8" pulley.

I've put a lot of thought into this so far and discussed it quite a bit with O-gauge. However, two major issues may occur.

1) Will it clear the hood? Montelibre's pulley didn't clear the hood so he has a small hood vent installed which the pulley sticks into. I could do that if it doesn't but I already have GTP hood vents installed which I would like to keep. Maybe I could do a slight bulge. Or I have spoke to Brown Dog about making a set of engine drop brackets. They said it would be no problem. Maybe 1" would be all that is necessary. That would give me a better angle for the front shaft, and worse for the rear. I have an SYE in the rear so that won't be an issue. I could also install a transmission cross member drop as well, keeping it all in line. I'm not too concerned about cooling fan interference as I plan on going to all electric.

2) Ping. My stroker wasn't built around forced induction, so my compression ratio is a bit high. I also have 6* of advance over stock programed into the PCM and another 6* of advance from my CPS relocation mod. For a total of 12* of advance over stock. I can pull back timing by removing the CPS mod and via the FIC. However, there is the possibility that it may still ping under boost. That is why I plan on tapping the throttle body adapter plate for water/methanol nozzles. http://www.naxja.org/forum/showthread.php?t=1088823 Hopefully I won't need the water/methanol injection right away and I can run just by pulling timing for now.

3) All blown up.

So besides the SC I will need:

-Injectors

-Aluminum plate

-Bypass actuator

-Larger pulley

-Modified steering pump

-Steering remote reservoir

-various fitting for vacuum

-pulley

-Larger throttle body (future)

-Water/methanol injection (future?)

I'll keep this thread updated as I go. I don't have a time frame, but the biggest hurdle now it cutting down the intake manifold and getting a plate welded on.

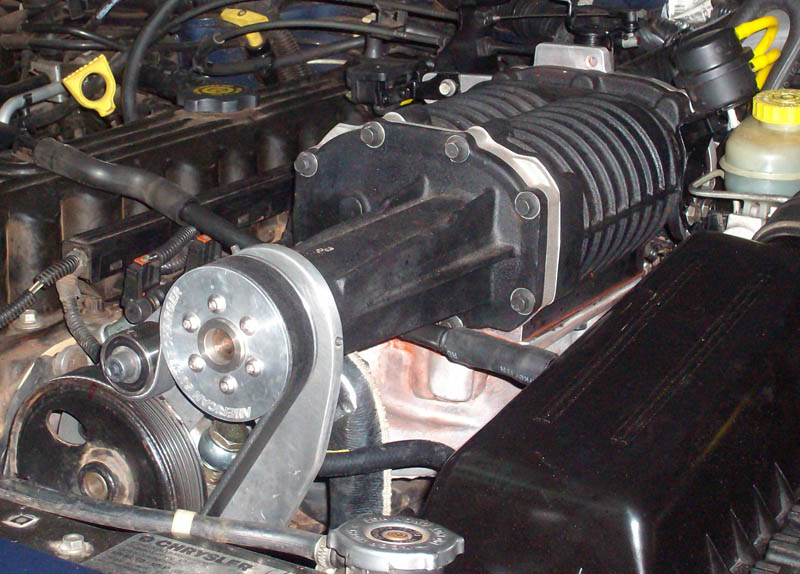

Pics of my actual MP90:

Output:

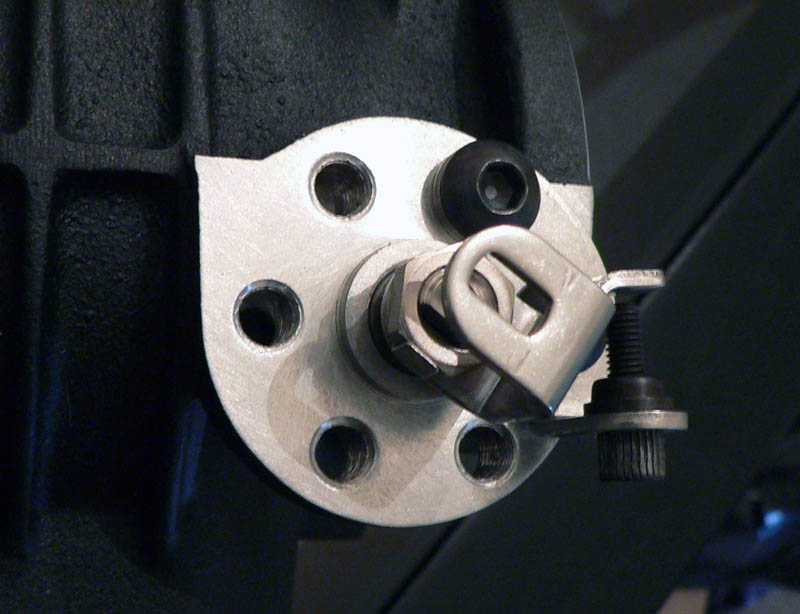

Bypass valve external arm.

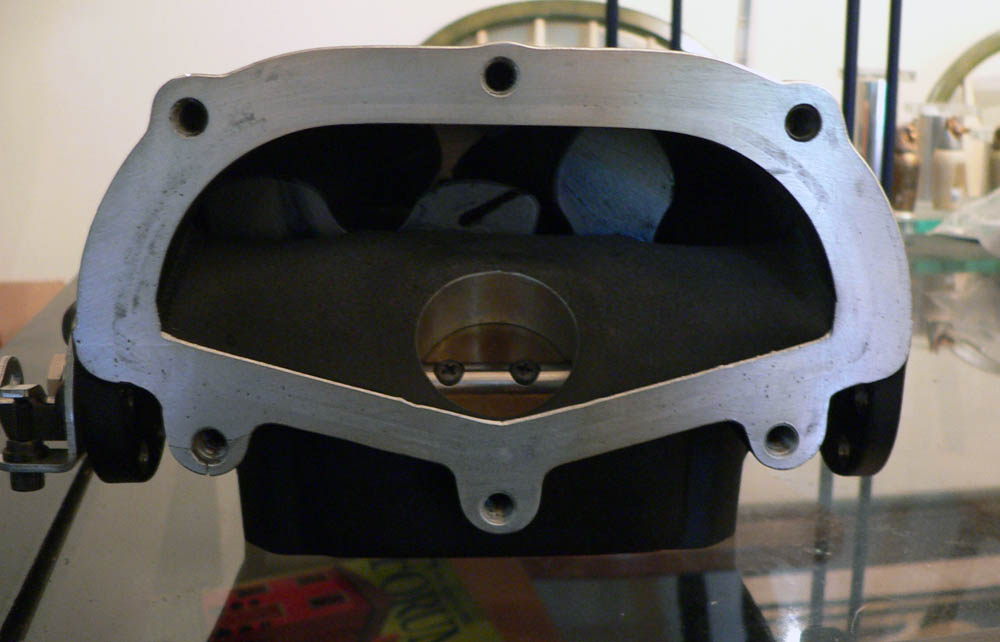

Input w/ bypass valve visible:

Case, blue is the bearing lube:

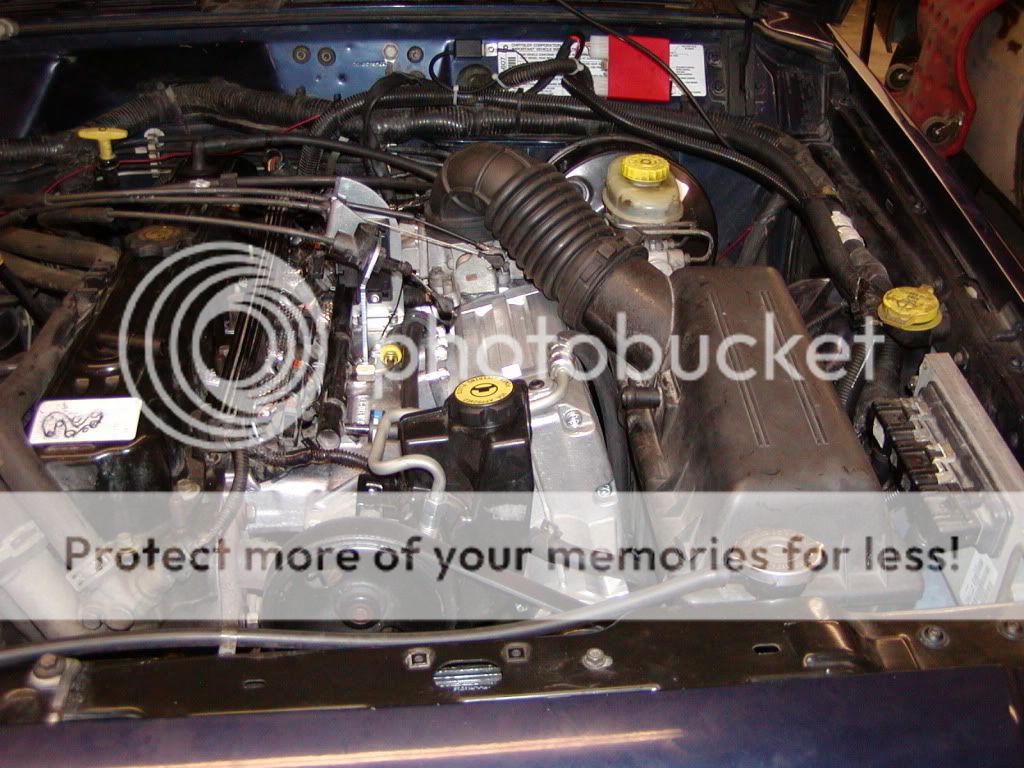

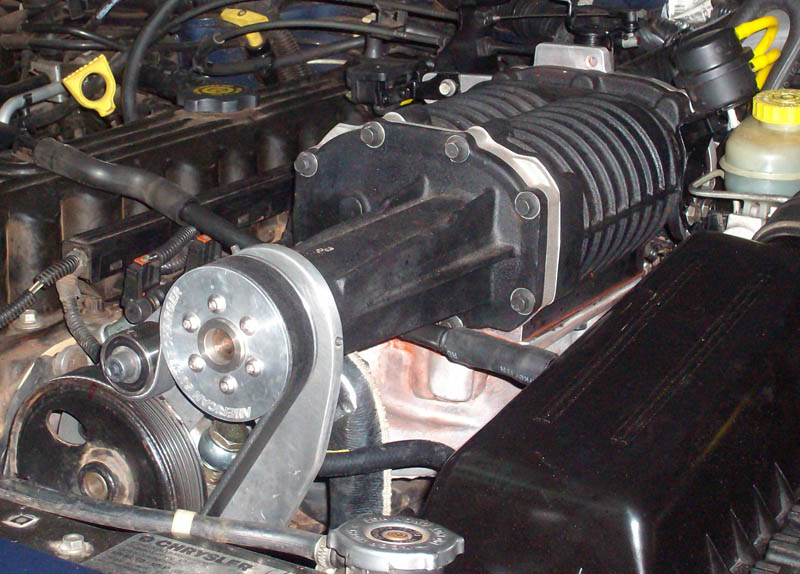

It will be going on this:

About a year ago I've looked for a Magnuson MP90 supercharger on ebay with no success. I put the thought aside but saved the search, which I had forgot about. A little over a week ago ebay sent me an email with a single match. An MP90 in near perfect condition. So, I bid and I won. Funny thing is that a day after the auction ended another on came up exactly the same. It sold for a little less, oh well.

I don't know what it came off of, but the seller stated "It looks to have been re manufactured and never installed". I received it today and it is in like new condition. It looks to have been bolted on to something, but it has no signs of actual use. The rotor's Teflon coating is untouched, no nicks in the rotor tips and no scores in the case. Basically a new supercharger.

This is a 4th Generation MP90. It differs from the 3rd generation M90 in a few ways. It's total height is slightly lower (5.30" vs 5.42"), it has an internal bypass valve, the outlet and inlet are different (inlet can accommodate a TB w/ an adapter plate), and it is said to be more efficient. The bypass actuator can also be positioned on either side in any number of positions.

This isn't something that hasn't been done before. I got the idea from Think!Performance's kit. http://www.4wheeloffroad.com/techarticles/engine/131_0803_40l_jeep_xj_cherokee_supercharger_kit/

Also, I later found that Montelibre on JeepStrokers installed one on his stroker:

Think! had a plate bolted to a slightly modified 99+ intake manifold, with some cut outs for the passenger side SC bolts. Montelibre also had a plate bolted to the intake manifold using a bit less modified manifold than Think! but he also made a plate to go between the SC and manifold, making bolting it on a bit easier.

For mounting it my plan is to cut the manifold top off as much as possible with and angle cut toward the driver side. Then weld 1/2" aluminum plate over it. The angle cut is to drop the snout as much as possible to prevent any interference with the hood. Then make an adapter plate (like Montelibre) to bolt to the bottom of the MP 90, which would then bolt to the modified manifold. The manifold will be coated in a heat barrier coating and I will also use a form of adhesive heat wrap, which I am already using on the manifold I have now. I am also planning on borrowing Montelibre's snout support/pulley plate idea, which would support the snout better and give more belt wrap on both the MP90 pulley and steering pump. I am unsure how to attach it to the snout yet, but looking for a good solution. The power steering pump will obviously have to be modified with a remote reservoir and possibly a different high pressure fitting. I am not 100% sure what to do about the pump, but I will cross that road when I get to it. I will obviously have to lose the Volant air tube, but plan on keeping the air box and Amsoil air filter.

The back of the MP90 will get a plate which will house the various vacuum lines and the throttle body. I plan on designing it to fit a 68-70mm throttle body in the future. Also, I plan on drilling and tapping it for water/methanol injection nozzles, which may come later.

For fuel I plan on using the AEM FIC6 with larger injectors. Size is undecided as of now.

This will be going on my 4.6L stroker. It has a static compression ratio of 9.54:1 and a dynamic compression or ratio of 8:1. Because of this I will be shooting for a boost of 4-6psi. I plan on using a 2.8" pulley.

I've put a lot of thought into this so far and discussed it quite a bit with O-gauge. However, two major issues may occur.

1) Will it clear the hood? Montelibre's pulley didn't clear the hood so he has a small hood vent installed which the pulley sticks into. I could do that if it doesn't but I already have GTP hood vents installed which I would like to keep. Maybe I could do a slight bulge. Or I have spoke to Brown Dog about making a set of engine drop brackets. They said it would be no problem. Maybe 1" would be all that is necessary. That would give me a better angle for the front shaft, and worse for the rear. I have an SYE in the rear so that won't be an issue. I could also install a transmission cross member drop as well, keeping it all in line. I'm not too concerned about cooling fan interference as I plan on going to all electric.

2) Ping. My stroker wasn't built around forced induction, so my compression ratio is a bit high. I also have 6* of advance over stock programed into the PCM and another 6* of advance from my CPS relocation mod. For a total of 12* of advance over stock. I can pull back timing by removing the CPS mod and via the FIC. However, there is the possibility that it may still ping under boost. That is why I plan on tapping the throttle body adapter plate for water/methanol nozzles. http://www.naxja.org/forum/showthread.php?t=1088823 Hopefully I won't need the water/methanol injection right away and I can run just by pulling timing for now.

3) All blown up.

So besides the SC I will need:

-Injectors

-Aluminum plate

-Bypass actuator

-Larger pulley

-Modified steering pump

-Steering remote reservoir

-various fitting for vacuum

-pulley

-Larger throttle body (future)

-Water/methanol injection (future?)

I'll keep this thread updated as I go. I don't have a time frame, but the biggest hurdle now it cutting down the intake manifold and getting a plate welded on.

Pics of my actual MP90:

Output:

Bypass valve external arm.

Input w/ bypass valve visible:

Case, blue is the bearing lube:

It will be going on this:

Last edited: