Root Moose

NAXJA Forum User

- Location

- ON, Canada

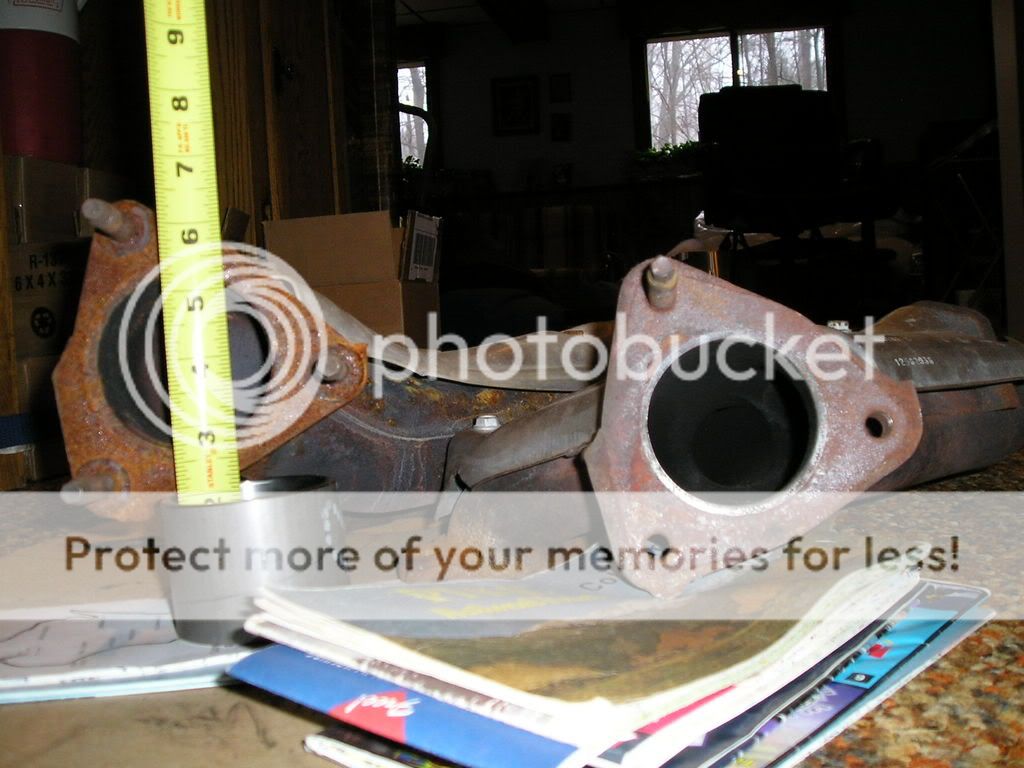

Great price and condition!

If/when I do my swap I've gotta get something from down south shipped to upstate NY. Similar mileage engines up here are all flaky grey from corrosion already.

If/when I do my swap I've gotta get something from down south shipped to upstate NY. Similar mileage engines up here are all flaky grey from corrosion already.