tbburg

NAXJA Forum User

- Location

- Scottsdale AZ

This is probably only a problem with the Jeep style front 4-link suspension.

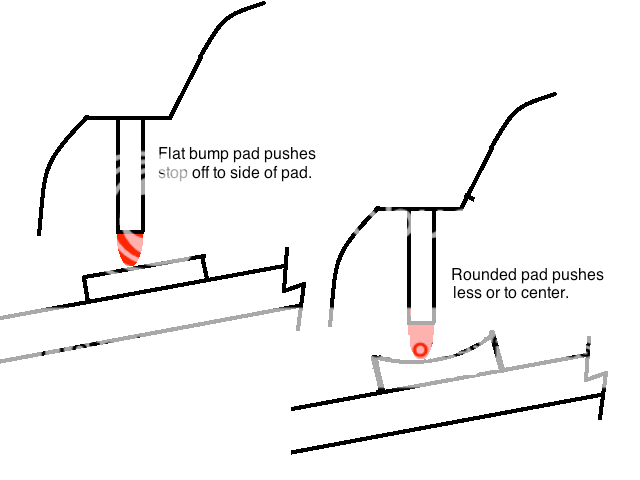

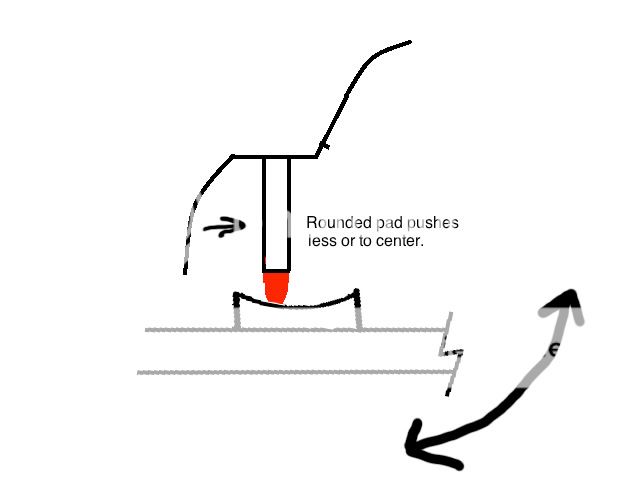

Because the bump stop is mounted on a pylon in the middle of the spring, it has little lateral support, and a fairly long "lever arm" acting on the bump stop. When you hit the stops, there is no way the bumper is always going to be perpendicular to the pad when it hits. Because of this, the bumper is always going to try to slide off the pad, putting all the lateral force on the pylon mount. The harder you hit, the worse it is. Because we spent so much time smashing the bumps at speed, the desert/JeepSpeed/prerunner crowd sees a lot oof damaged stops, spring buckets, and other various suspension components.

What if, instead of a flat bump pad, you had a cup shaped pad, maybe 3/8"-1/2" deep in the center. Then, most of the lateral force acting on the bump stop would be forcing it toward the center of the bump pad, and not to one side.

What do you guys think? Way off base, or worth further thought?

Because the bump stop is mounted on a pylon in the middle of the spring, it has little lateral support, and a fairly long "lever arm" acting on the bump stop. When you hit the stops, there is no way the bumper is always going to be perpendicular to the pad when it hits. Because of this, the bumper is always going to try to slide off the pad, putting all the lateral force on the pylon mount. The harder you hit, the worse it is. Because we spent so much time smashing the bumps at speed, the desert/JeepSpeed/prerunner crowd sees a lot oof damaged stops, spring buckets, and other various suspension components.

What if, instead of a flat bump pad, you had a cup shaped pad, maybe 3/8"-1/2" deep in the center. Then, most of the lateral force acting on the bump stop would be forcing it toward the center of the bump pad, and not to one side.

What do you guys think? Way off base, or worth further thought?