hubs97xj

NAXJA Forum User

- Location

- Fort Wayne, IN

Hee is my expierence with the magnaflow kit...

It's Dynomax, not Magnaflow. The tip is stainless steel, not chrome. It will rust and fall off regardless, but I like details.

Hee is my expierence with the magnaflow kit...

It's Dynomax, not Magnaflow. The tip is stainless steel, not chrome. It will rust and fall off regardless, but I like details.

What did you ended up with?The only problem with this is that as of 9 months ago, there is no one in Vegas that has a mandrel bending machine. I called every place in the phone book and, unfortunately, no one has one. If someone knows of one, please let us know.

It's pairly rusted but still usable but bc of my "minor ocd", i rather replace the whole system :clap:.if your stock one isn't rusyed use it with a new end on it (the part that bolys to the header) and that should get rid of the crimp in it which will make it perfectly fine unless you have a built stroker.

:huh:^this

support your local exhaust shop. in my experience they have been cheaper and the end result is better.

How did i missed your post....nice details, thx.Hee is my expierence with the magnaflow kit...

$40 was after the $75 rebate, which is no longer available.

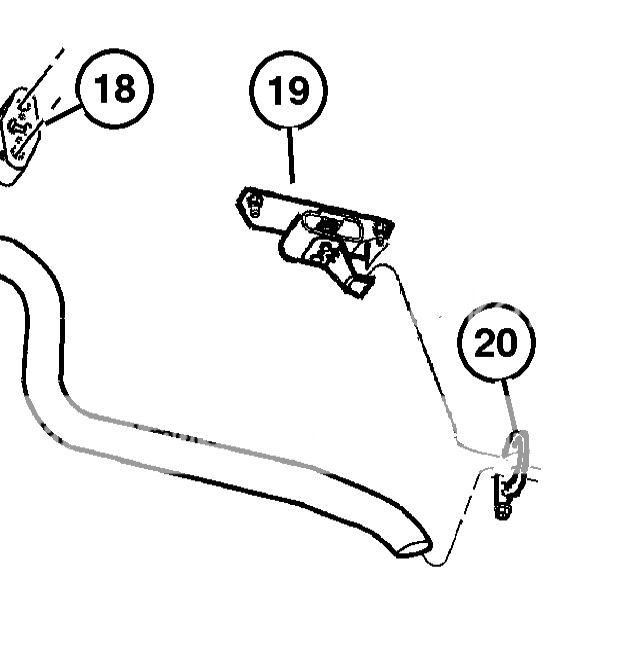

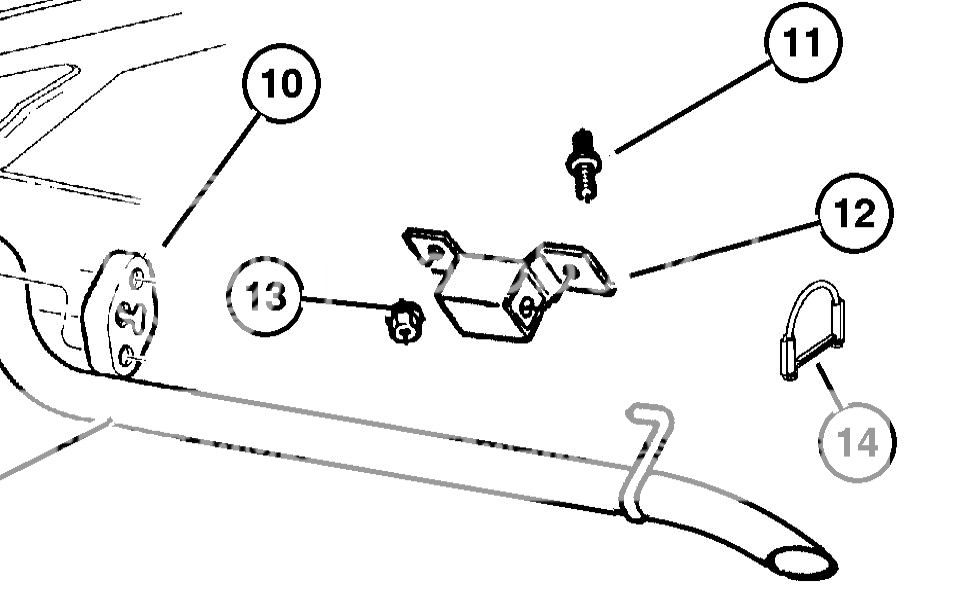

I have created a turn-down, and will be welding that on when ever I get a chance... hope that is this weekend. If you get the correct exhaust for your year, unlike what I did, it will be a bolt on affair from the cat back. I just HATE the chrome tip of the 97~ and the z-bend of the ~96.

Thx, i'll look into that.On my 00,I put a banks header on and used the Walker head pipe 55277,Magnaflow converter and the dynomax exhaust. Everything fit good no issues. Before anyone says anything my was a early 00 with federal emissions. Same set up as a 99.

Thx.At stock height, there's not much room for the downpipe (hence the kink), and the front driveshaft yoke will make room. Once you're above stock height, you don't have that issue, or at least I don't.

I started with the Dynomax catback, then later did the intake and APN manifold swap, Maremont downpipe (won't recommend), and a Walker cat, replacing the SuperTurbo muffler with a smaller "turbo" muffler, and adding a short piece of pipe to make up the difference. All the clamps have since rusted away/broken, including the rear hanger from the Dynomax kit. Replaced all clamps with SS band clamps. Had to have a shop tweak the downpipe, as it was banging against the crossmember.

Exhausts are covered in pretty good detail around here; I'd do a lot of Google searching (add site:naxja.org to your searches) and reading. There's a lot of good advice floating around, and I could have saved money and time, had I not ignored some of it.

How did i missed your post....nice details, thx.

Care to share which system you have?

Thx.

Just had mine installed today. Have a short vid over on FB.

http://www.facebook.com/A2theJackson#!/photo.php?v=10100405371439307&set=vb.12612911&type=2&theater

Quality is not great from my phone but you can get an idea. Used the stock 2000 downpipe and cut it just before the stock cat. everything back is brand new. Set me back $250 for the labor/misc parts and I had the muffler/cat already.

What did you ended up with?

Did you got the downpipe replaced?

I ended up just getting a parts house replacement for right now. It's better than stock but not what I wanted. It has those crappy kinked bends. When I get more time, I'll do some more research and find a better one, but It'll have do for now. I'd still like to find a shop that has a mandrel bender.

It has those crappy kinked bends.

If you're going to take the time/effort/$$ to get an etirely new exhaust system, INVEST IN SOME VBAND CLAMPS. Piece the exhaust together as you usually would, weld it, then just cut into sections and weld in your flanges. Makes removing your exhaust CAKE when you need to.

Problem is i don't have any fabrication tools...not even a freaking vise.

I would prefer a system without welding pls.

That was helpful :listenmus:rtm:

I love v-bands, but I just can't see the feasibility when someone wants a system without welds and/or on a budget.

It doesn't seem like anybodys addressed your which header question.... Personally I would go with the APN header. The primary tubes are more equal length and should produce a better power curve. Whether you'd be able to tell the difference, idk.

I was reading some tech articles on exhaust with kink bends and they say for a stock to slightly modified motor they say it really doesn't hurt performance any. This is mainly because the kinks are only present where the exhaust tubing bends. The kinks are formed on the inside of the bend and the primary exhaust forces are on the outside of the bend due to the inertia from the turn in the exhaust.

Now If I had two choices, kink bends vs madrel, Id pick the mandrel. However, if my kink bend pipes were in good shape I'd just leave them untill then needed to be replace..... and that my 2 cents :gag: :spin1: