BRIANHO13

<- Yum Chocolate

- Location

- Spring, TX

Flap wheels work well, those paint removal wheels work well as well.

Flap wheels work well, those paint removal wheels work well as well.

i know its been answered, but what wheels do ya'll use to clean your framerails? i have some flap discs, but thats all i have. wondering if i need to make a harbor freight run.

If you are talking about the undercoating stuff, heat it up with mapp gas and it comes off with a putty knife/scraper like butter. I got both sides of my XJ done in less than an hour.

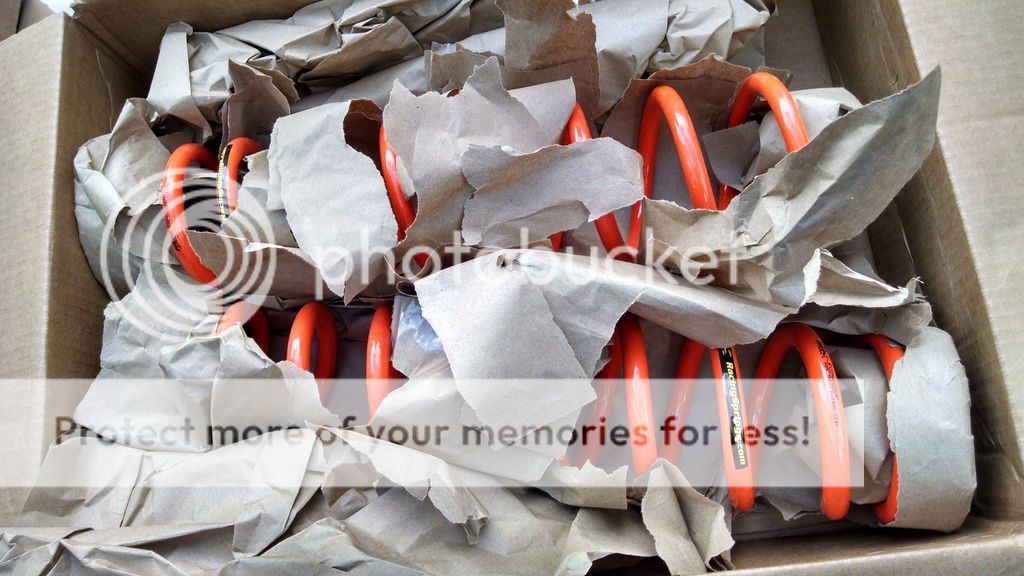

got them for about half off what they cost new shipped to your door. they will fit the overall theme of this jeep nicely and will cover my dirty stock seats until i can find some nicer seats. here is what they actually look like:

l

what seats do you need? I have many sets. I have a full set of gray ones, front and rear.

Bed is yours if you still want it, otherwise it will go to Doug.

He's gonna put pretty ricky in storage for a bit until he can do a restoration on that one too.

Glad they are fixing the mix up for ya. Get a hold of me if ya spend any time is DSM on your trip.

Ha! Cool. My shops about a mile south of his store, work till 3pm on Saturday then in the shop all day Sunday if ya want to stop by.