jbjustin33415

NAXJA Forum User

- Location

- West Palm Beach, FL

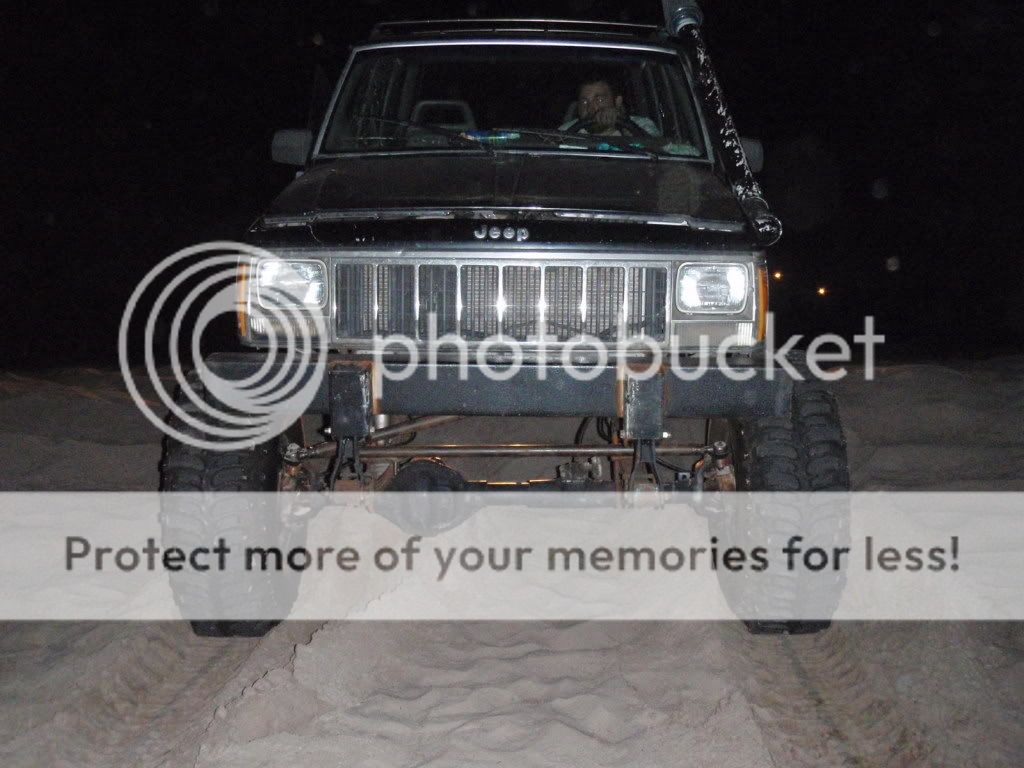

I also have to drop the crossmember down a few inches but keep the transmission/transfer case in the same place to clear my front driveshaft. With the addition of the "U Channel" I would be able to through bolt the crossmember I build and it would be nice and strong.

What would you recommend I do in this situation?

What would you recommend I do in this situation?