leftlanetruckin

NAXJA Forum User

- Location

- Mid Mo

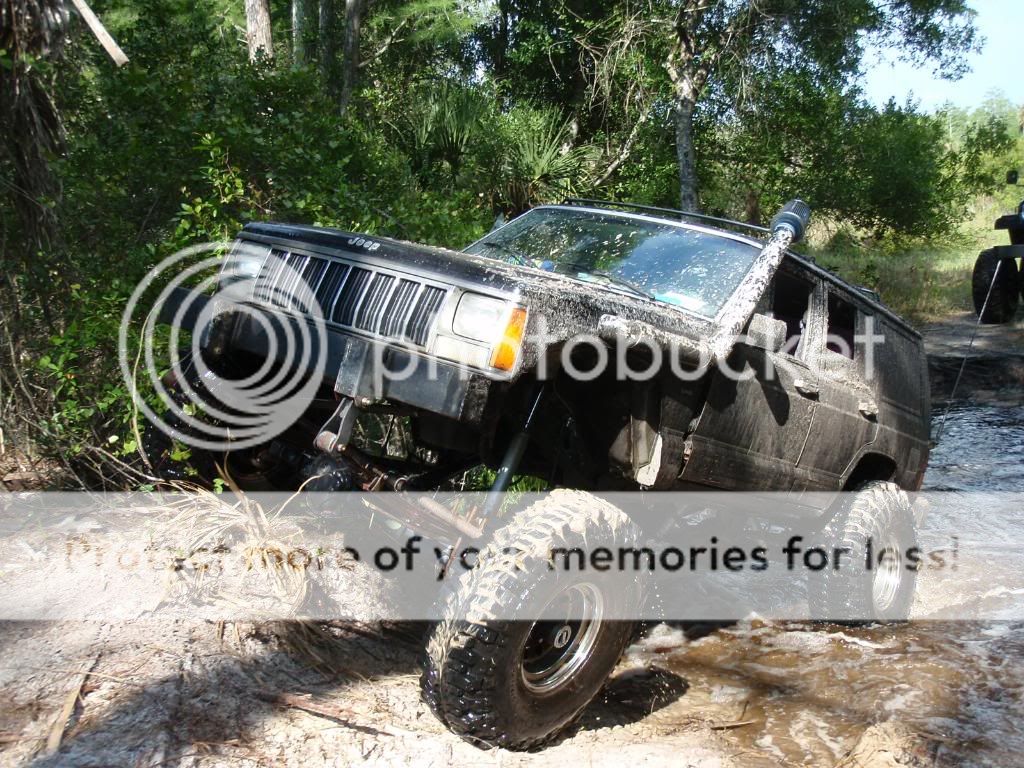

hes leaf sprung up front.....

yeah i know, thus my comments regards his front shackles and the

"shackle reversal" debate...:yelclap:

the OP did say he was "going to his uncles shop to do an alignment", so i threw it out there that i bought a caster/camber gauge to save having to go to shops all the time whenever i changed anything. i doubt a regular alignment shop will want to remove/replace/remove/replace the front u bolt plates to get the alignment in specs. only way to tell is by trial and error sometimes, especially on a total custom setup like my jk rubi axles and the OP's setup. thus i stand by my previous post of a caster/camber gauge being worth its weight in gold to purchase, regardless of coils/leafs/coilovers/torsion bar/whatever.

martin