Okay, still trying to get caught up:

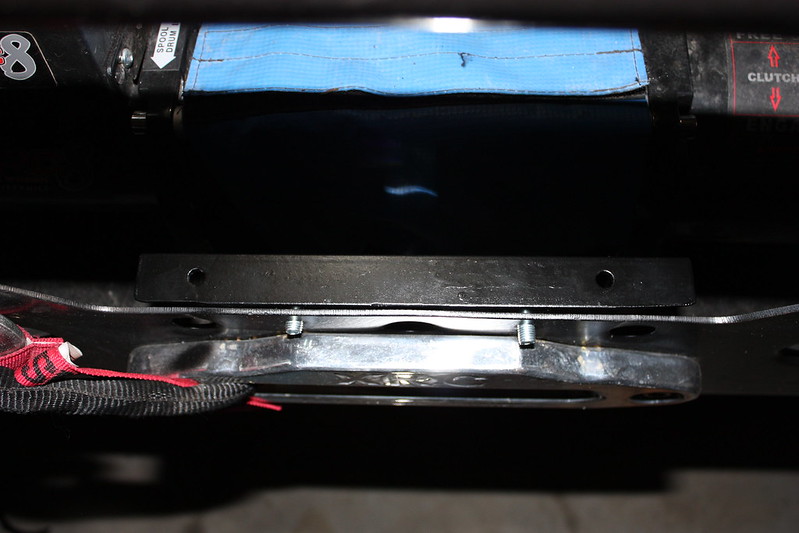

In preparation for my summer trip I got a lot of little projects knocked out. First, I painted my track bar I built, I was temped to use black but resorted to my standard upgrade color at the last minute:

It was still too cold to let it dry in the garage so I brought it into the bathroom to dry... My wife loves it when I do stuff like that! :twak:

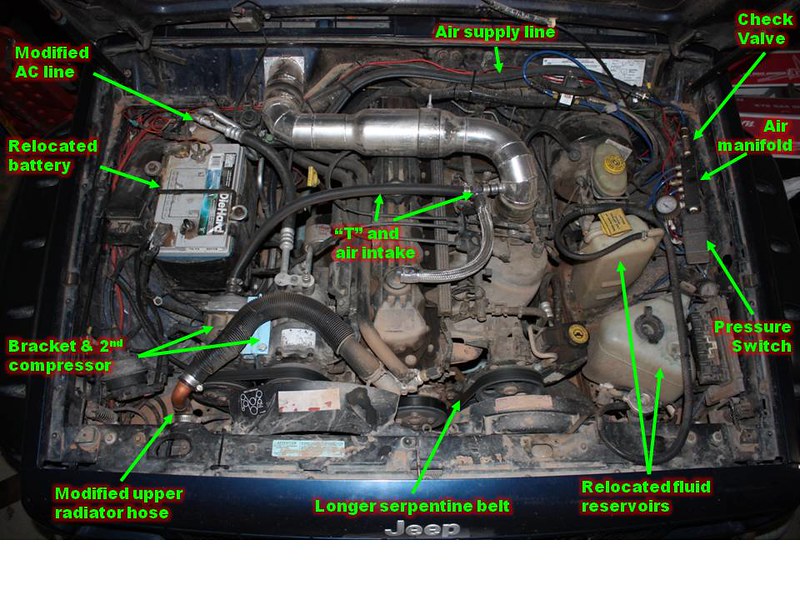

Then I finally got around to charging my AC. It has been needing it since I broke a line during my battery relocation mod last November; I finally bough a manifold from Harbor Freight:

I used one of their air compressor attachments vacumes, I could only pull about 20 bar for 10 min or so before I got conerned that I might damage my compressor... Then I put a 30 bar vacuum on it and let it sit for a few hours to check for leaks. It didn't seem to lose any vacuum so I went ahead and charged it up. I did end up leaking some freon over the next few weeks but it is still blowing cold so I'm not sure if the stop-leak in the freon fixed some pin-hole leaks or what. I suppose I'll know for sure in another few months.

Then on a trip up Farmington Canyon my XJ temp was behaving strangly. at seemingly random intervals the temperature needle would immediately SPIKE to 250°. I replaced the Temp sender the next day, ran back up the canyon and still had the same result. So then I replaced my thermostat and I was having trouble getting it to seal right, here you can see the leaking:

And I figure it was just too pitted to seal correctly anymore:

So back to the parts store and grabbed a new housing and threw that in:

I ran back up the canyon and had the same result. This time when I popped the hood it looked like the radiator cap had squirted a little. So I drove straight to the parts store, replaced my radiator cap and ran back up the canyon (good thing it's close!) and had the SAME result...

So

I started a thread asking what could be going on. Was recommended that I perform a coolant flush, so I did and ran some of this in it for a few days:

Doing research I discovered all about the infamous 0331 aluminum head my 2000 XJ came with and how they often crack... So I became more than a little worried about that possibility! When I picked up the coolant and cleaner I rented a pressure tester - I read that you can pump up the preasure on your system and then look inside the oil fill cap and often if there is a leak you will see it in there.

Fortunately, no signs of a leak:

There also has never been any signs of condensation in my oil, nor were there any signs of coolant on top of the head.

I was happy about that but still unsure of what was causing my trouble. The good Dr. (Moab that is) told me about a neat little "feature" on these 2000-2001 XJs:

on the newer jeeps right past 220 the computer will peg the gauge, kick on the "check gauges" light and sound a chime.

I fought this forever in my jeep then found out it's programmed into the ECU. Your jeep isn't actually running that hot, it's just kind of like a sophisticated idiot light.

I'm pretty sure this is what you were seeing. If I'm guessing right, as soon as you saw it, you backed out of it and it dropped back down to 220 or so just as fast as it spiked...correct?

Well that was right on the money. This has to be just about the stupidest thing I've heard of on my Jeep! I would understand the dinging and flashing the "Check Guages" light if the temp is climbing above 220°, but to have the temp gauge reflect an inaccurate temperature reading??? That's just moronic. :nono: :flamemad:

uke:

Anyway, since I've done all this work I've only had this happen to me once more, and that was climbing a long hill doing about 55 MPH coming back from Lake Tahoe. I kept on the gas but we crested the hill before the 3 min was over. (that's how long I've read this "warning" lasts.) When the temp went back to normal it was back at 215°ish.

For now I'm calling this a non-issue. I plan to buy a

bluetooth ODB-II scanner and leave it plugged in while I run Farmington Canyon again, but that will probably end up being next spring at this point... (The scanner connects to your phone and, using free software, can give you all sorts of information, to include engine temps. :thumbup

In another conversation about engine temps, a :

: member told me about how he never really knew how hot his tranny got until he installed a tranny temp guage (and now he wishes he never did!) So long-term I'm thinking I'd like to get an external tranny cooler and not route it through the radiator at all. I'd also prefer to have it AWAY from my radiator and not in front as most people run them, and of course with an axillary fan on it. But I have no idea where to fit it so that is an issue for another time/day/year...

: member told me about how he never really knew how hot his tranny got until he installed a tranny temp guage (and now he wishes he never did!) So long-term I'm thinking I'd like to get an external tranny cooler and not route it through the radiator at all. I'd also prefer to have it AWAY from my radiator and not in front as most people run them, and of course with an axillary fan on it. But I have no idea where to fit it so that is an issue for another time/day/year...

: member told me about how he never really knew how hot his tranny got until he installed a tranny temp guage (and now he wishes he never did!) So long-term I'm thinking I'd like to get an external tranny cooler and not route it through the radiator at all. I'd also prefer to have it AWAY from my radiator and not in front as most people run them, and of course with an axillary fan on it. But I have no idea where to fit it so that is an issue for another time/day/year...