-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

a cooling idea thats brewing and needs a little input

- Thread starter Ben_Dyer

- Start date

wolfpackjeeper

NAXJA Forum User

- Location

- 500' and 500KCAS, RAF lakenheath

measure the free space between the back of the grill and the front of the condenser. Then go buy a pusher type fan that will fit in that space.

Why would you suddenly be worried about rocks breaking a plastic fan when you were not afraid of them bashing the condenser and radiator?

Why would you suddenly be worried about rocks breaking a plastic fan when you were not afraid of them bashing the condenser and radiator?

winkosmosis

NAXJA Forum User

- Location

- Maui, Hawaii

ummmm plastic.... metal no one said worried just asking questions to understand with better detail

The radiator I think is more vulnerable to rocks than a plastic fan. Those fins are thin like foil

JAS

NAXJA Forum User

- Location

- Ann Arbor, MI

I think that moving some of the heat load from the radiator will do more than buildge fans will

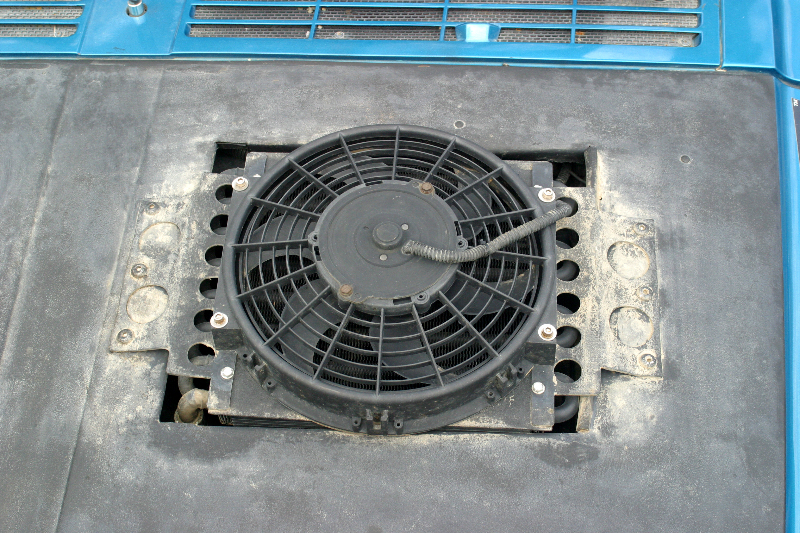

This for either the oil or the trans.

This for either the oil or the trans.

I think that moving some of the heat load from the radiator will do more than buildge fans will

X 2

Unless the radiator/gearbox heat exchanger is of benefit because of driving location climate .... bypass the useless thing.

Even tho I have a better radiator than the factory one ... I attribute significant cooling benefit to both the engine and the gearbox after bypassing the radiator/gearbox heat exchanger.

Altho the improvement is a bit more obvious - for us when we bypass it, as chrysler chose to bang the thing in the wrong end of the radiator, (opposite to U.S. setup) for sales in our hotter climate ...

HaleYes

NAXJA Forum User

- Location

- Clay County, IL

after my last horrable idea for a gas tank skid i hope this one has a little bit more ground to stand on.....

ok so after seeing Yellaheeps jeep in Moab. I wanted to do something similar to his boat vents on the side. i am wanting to do a pair of them one on each fender, using something like these vents....

I then had a spark of an idea to maybe add a blower to force air out of the engine bay using something like this little guy here.....

a guy could create a cross breeze using two blowers one for intake and one for exhaust. throw these guys on a switch or dual switches and you could flip them on while wheeling for added air flow and cooling. or maybe toss a blower after a cone style filter for a forced air intake setup right in the engine bay or connect it to the vent for forced cold air intake.

thoughts, comments? i know this would help with cooling but would it have potential to cool too much?

Why? If you're stock cooling system isn't working, there's an issue somewhere that could be fixed. Are you having overheating problems?

ok guys my cooling system is fine i have never had it overheat on me. never boiled over, never blown a seal, never had a problem. i liked the looks of Yellaheeps single vent and decided i wanted a pair, one for each side.

sooooooo.....................

THE VENTS ARE PURELY COSMETIC and i like the look of them.

THE BLOWER WAS A SECOND FIND THAT HAD POTENTIAL TO OFFER A SLIGHT BENIFIT IF COST WAS LOW. but in the end the cons of adding a blower were slightly higher than the pros. and thus the idea has been scrapped.

i am washing the idea of using the blowers. for gods sake read the whole thread i stated i was going with just the vents for looks but going to make them functional just because they are there and why not do so.

why do you guys put vents in the hood if your cooling system works just fine?

i plan to install just vents that are functional to allow extra air to dissapate from the engine bay to aid and add to the cooling systems perfectly functioning ability.

sooooooo.....................

THE VENTS ARE PURELY COSMETIC and i like the look of them.

THE BLOWER WAS A SECOND FIND THAT HAD POTENTIAL TO OFFER A SLIGHT BENIFIT IF COST WAS LOW. but in the end the cons of adding a blower were slightly higher than the pros. and thus the idea has been scrapped.

i am washing the idea of using the blowers. for gods sake read the whole thread i stated i was going with just the vents for looks but going to make them functional just because they are there and why not do so.

why do you guys put vents in the hood if your cooling system works just fine?

i plan to install just vents that are functional to allow extra air to dissapate from the engine bay to aid and add to the cooling systems perfectly functioning ability.

- Location

- Aransas Pass, Texas

Relax man, nobody was picking on you. Some good points were brought up in this thread.

Those vents can look nice, no doubt.

Now there are marine squirel cage bilge blowers that can run longer... if you want to investigate that.

Those vents can look nice, no doubt.

Now there are marine squirel cage bilge blowers that can run longer... if you want to investigate that.

ok guys my cooling system is fine i have never had it overheat on me. never boiled over, never blown a seal, never had a problem. i liked the looks of Yellaheeps single vent and decided i wanted a pair, one for each side.

sooooooo.....................

THE VENTS ARE PURELY COSMETIC and i like the look of them.

THE BLOWER WAS A SECOND FIND THAT HAD POTENTIAL TO OFFER A SLIGHT BENIFIT IF COST WAS LOW. but in the end the cons of adding a blower were slightly higher than the pros. and thus the idea has been scrapped.

i am washing the idea of using the blowers. for gods sake read the whole thread i stated i was going with just the vents for looks but going to make them functional just because they are there and why not do so.

why do you guys put vents in the hood if your cooling system works just fine?

i plan to install just vents that are functional to allow extra air to dissapate from the engine bay to aid and add to the cooling systems perfectly functioning ability.

- Location

- Aransas Pass, Texas

And I do not agree with the cat that says bilge blowers should be ran until a boat reaches plane, but hey, what do I know.

Jabsco has a full line to look at, not the inline. Not that I would run either to try to cool an engine.

Jabsco has a full line to look at, not the inline. Not that I would run either to try to cool an engine.

that post was more for those who keep asking why.

marine squirl cage blower...... i really dont think blow drying a squirl from the ocean will help here but ill look into it any way.

the squirl cage blower is the heavy duty blower by jabsco i was refering to earlier. my plan there is to install the vents now, and then if i decide i have some free cash to drop on a blower, ill pick one of those up. the plan for hook up will be to run a line from the outlet to the driver side vent and posably a line running the length of the firewall (sitting down a little ways near the trany tunnel) with slits or holes cut in it to the suction side of the pump. thus aiding in evacuating air out of the engine bay that is getting trapped there.

after some testing i found the higher temps to be in the upper corners (near brake booster and ac canister thingy), and just above the tunnel. i wish i had taken some notes on the temps but ill be doing this again once i have the vents for before and after numbers to show these do or do not help. i have a strong feeling these will reduce temps in a measurable number maybe 5 -15 degrees maybe even more.

and i ahve no idea what you guys are talking about with boats reaching planes either soooooo.

after some testing i found the higher temps to be in the upper corners (near brake booster and ac canister thingy), and just above the tunnel. i wish i had taken some notes on the temps but ill be doing this again once i have the vents for before and after numbers to show these do or do not help. i have a strong feeling these will reduce temps in a measurable number maybe 5 -15 degrees maybe even more.

and i ahve no idea what you guys are talking about with boats reaching planes either soooooo.

after some testing i found the higher temps to be in the upper corners (near brake booster and ac canister thingy), and just above the tunnel. i wish i had taken some notes on the temps but ill be doing this again once i have the vents for before and after numbers to show these do or do not help. i have a strong feeling these will reduce temps in a measurable number maybe 5 -15 degrees maybe even more.

Can confirm your high temps in the corners by results with my vehicles ....

Theres a TJ writeup that shows the - principles - of what happens under an XJ bonnet, here --> http://www.oman4x4.com/hoodvents.htm

When you look at the TJ image ... there is a noticeable lack of heat in the centre of the bonnet compared to the area behind the fan, the two rear corners .... and along the firewall.

Thats coz the TJ hood is high enough above the engine ... not to wear holes in the padding

Along with a less cramped engine bay.

Googling some wind tunnel images will also give you an idea of how to make "slipstream" effects work for you.

High temps above the tunnel are to be expected being close to the engine altho that temp does lower ...

a). When the rad air intake is improved so as to flow through to the rear better.

b). When air is allowed to escape at the corners with a spaced hood ... with an induction blocker fitted.

c). By fitting a cowl hood which introduces ( inducts ) cooler air at speed ... keeping in mind that a sensor fitted above the tunnel - will then measure the temp of that new, incoming air ... rather than whats happened to the old air ...

A benefit of the cowl hood in addition to its low speed venting action is the clearance space above the engine.

Dont know what happens with flat bonnet vents except simple physics, means they allow naturally rising heat to escape at slow speeds ..... and can turn into scoops at higher speeds if mounted in the wrong position.

Im more interested in improving overall outgoing airflow ... rather than just chopping holes in the hood ... as better outflow ensures max intake thru the radiator ... and under bonnet temps improve as a result of the moving air.

Last edited:

as soon as the vents get here in the mail i will have to do the testing methadology he used to see what i come up with. the only differance is i am using a laser thermometer to measure the temps after i stop, and i will plot them the best i can.

I have to make it clear that the results i find are biased to my XJ and only those that have a 2 inch hood scoop. they most likely will differ from those who have spaces and or regular hoods.

i will also be adding info based on the removal of my A/C once i remove the condenser and everything associated with it except the A/C pump since i will be using that for OBA.

i agree with you carves i am attempting to improve the outgoing air as well. so in the process i will be replacing the fan shroud (i broke doing my engine mounts) removing the A/C condenser and adding an elec fan switch to the mix. i hope for this to have fairly indepth measurements so i can utilise the best method for evacing air.

I have to make it clear that the results i find are biased to my XJ and only those that have a 2 inch hood scoop. they most likely will differ from those who have spaces and or regular hoods.

i will also be adding info based on the removal of my A/C once i remove the condenser and everything associated with it except the A/C pump since i will be using that for OBA.

i agree with you carves i am attempting to improve the outgoing air as well. so in the process i will be replacing the fan shroud (i broke doing my engine mounts) removing the A/C condenser and adding an elec fan switch to the mix. i hope for this to have fairly indepth measurements so i can utilise the best method for evacing air.

88 Wagonman

NAXJA Forum User

- Location

- Boise, ID

And I do not agree with the cat that says bilge blowers should be ran until a boat reaches plane, but hey, what do I know.

I didn't mean turn it on every time you are coming on and off plane, but that when you are below cruising speeds it needs to be running. Check out the operation and warning labels sometime, or better yet an owner's manual, they will confirm it. But what do I know, I have only been looking at those stupid labels for the past 12 years at work.

WebDog

NAXJA Forum User

- Location

- Center City, MN

No, not exactly. Boat engines are cooled by the water that they are floating in, the purpose of the bilge blower is because there is not adequate ventilation for fuel vapors unless the boat is cruising. It's purpose is NOT to provide cooling air or air for the engine.

It is also very handy when the genset actuator decides to nearly catch fire and the engine room is full of thick smoke.

But the amount of air flow from those fans is not that great.

ok at LOW speeds like rock crawling does any one see the potential to suck hot air out of the engine bay, using a squirl cage blower that is ment for heavy/ constant duty use?

Im thinking a bunch of sweaty squirrels in a cage might generate more heat than the 4.0l .... :laugh:

oooops ... back to the world ....

Yes ....

a/.. Proved it with some cheap fans ... till they melted ...

b/.. If the fanclutch/e-fan arent up to task, for the driving requirements ... and more orthodox venting methods arent enough.

c/.. But .... Its probably something more of benefit on a comp vehicle rather than a daily use vehicle.

End of the day ... Its your vehicle so you can do what you want ... Checking before and after temps etc as you plan to ... will let you know how successful - or not .... the mod is.

I would suggest getting a temp device with at least one probe/sensor on a long lead so you can check under the hood whilst on the move.

Once the vehicle is stopped ... all the temps rise through heat soak & no air movement .... so variations have occurred by the time you get to open the hood.

The TJ writeup sums it up well .....

" Remember when I said “I already knew” where the heat was located? I was wrong! It wasn’t on top of the engine or even centered on the exhaust manifold as logic would suggest. Why is this? I have no clue, only guesses. I suspect part of this is due to the air movement caused by the fan, and part probably has something to do with heat being trapped between engine compartment components. "

:cheers:

Similar threads

- Replies

- 6

- Views

- 185