TonkaYJ

NAXJA Forum User

- Location

- Milwaukie Or

NICE! Glad to see you have a rig again that didnt take long at all Look forward to wheeling with ya again soon!

They're stiff.So you're pretty happy with the springs and leafs so far? I'm still looking at getting a set of those leafs, and maybe even some coils as well. Are the leafs flexing pretty good? How did your shackle angle come out and about how much lift did they net?

Thanks, Pat. I'm hoping to make some runs with you guys this year.NICE! Glad to see you have a rig again that didnt take long at all Look forward to wheeling with ya again soon!

Definitely keep me updated on how you like the setup down the road. I'm a little upset to hear the shackle angle isn't very good. I was really hoping BDS used a little longer main leaf. The coils sound like what I'm going for. I would really like my front end to be a little stiffer. I'm running Bilstein 7100's up front now in the 278/75 valving and although I haven't been offroad much with them the front end could definitely be a little stiffer. My coils are soft though (180 lbs) so that would be my next change before messing with the Bilstein valving anymore. I'm also looking to do a 3 link mid-arm (passenger upper) down the road as well so we'll see who gets done first. :greensmokThey're stiff.

The coils are noticeably stiffer than my old Rubicon Express springs. Paired with some Bilsteins, the front end is pretty firm. However, that's kind of what I was going for. I'm still getting use to it's handling off road, but the combo seems to do pretty good in the rough stuff. I'll admit I'm probably asking a lot from my short arms, but the springs/shocks I'm happy with.

The leafs are another story. I'm sure they're still getting broken in, so I'm giving it time. However, the length is too short in my opinion. Shackle angle is pretty vertical, and looks like most aftermarket spring angles. Can't really comment on the spring since I know the shackle isn't exactly working too efficiently as is. I know they seem to be pretty stiff like the BDS coils. Unloaded the rear end is pretty firm, but once I get some weight in the back the rear end starts working a bit more.

I'll run the suspension how it is probably the rest of the year, and then decide what to do with it. The idea I'm tossing around now is going with a custom mid-arm on the front, and a longer main leaf in the rear.

I'm a trend setter, what can I say.starting to feel Torxafied.. I just got my Tera 2low, Detroit locker (D30) and they are all sitting on a stack of Cooper STT's..

along with steel from Eastside steel..

:gee:

No regrets.Dustin what do you think of the allieds? sold off my trailreadys and my new build I'm thinking of using the allieds.

Looks great, definitely gonna fit better then the ones on the stocker. I think they are JCR, or JMR, or terra flex or...... I can't remember. Hell I don't even remember what I said that made Darren feel inclined to edit my post two days ago. I need sleep.

!!!1. id bet even this gets edited....

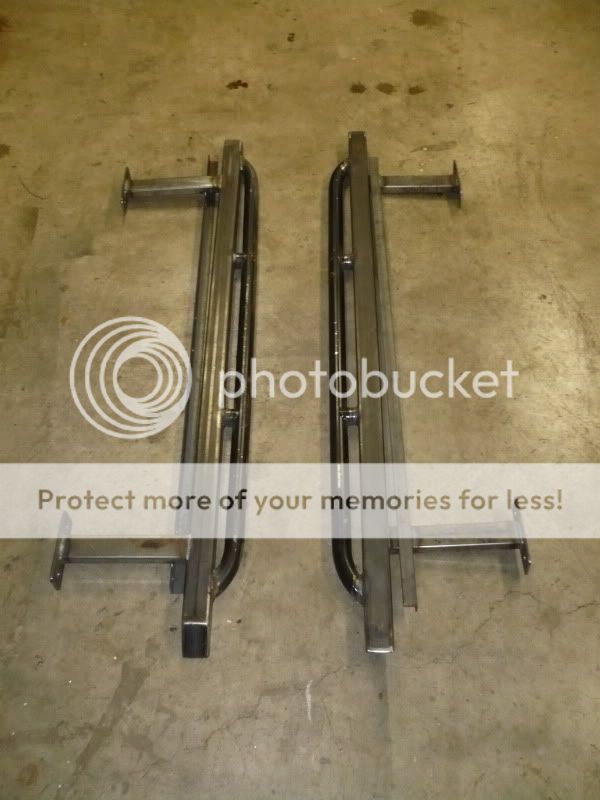

Got some primer and paint on the sliders this weekend. Bolted them on today. I'm happy with how they turned out.

Gales Creek ShellWhere did you get the sticker ( off road permit )??