-

Welcome to the new NAXJA Forum! If your password does not work, please use "Forgot your password?" link on the log-in page. Please feel free to reach out to [email protected] if we can provide any assistance.

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom Tie Rod

- Thread starter RªMB°

- Start date

jeep ride

NAXJA Forum User

- Location

- West Virginia 25064

Don't know thread size but one is left hand thread other is a right hand thread.Iron rock off road makes a 1.25 dia. tube for 66.00 plus shipping fyi.

Begster

NAXJA Forum User

- Location

- Cape Cod/Boston, Mass

In my opinion, its easier to get some thick DOM and some tube adapters, and weld them in. After factoring in the costs of taps, (left hand threads aren't cheap), it just might not be worth it.

If that doesn't work for you, then I can't really help you with the tap size, sorry.

If that doesn't work for you, then I can't really help you with the tap size, sorry.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

Taps are way to expensive to invest in for factory size threads.Why would you even consider it?I am going to machine a new tie rod for my XJ that is made out of beefier material, but I need to know the thread sizes of the tie rod ends. Anyone know what these are?

xjjeepthing

NAXJA Forum User

- Location

- Plymouth Indiana

Factory tie rods are 11/16-18 thread, Speedway motors has left and right hand thread taps in that size

http://www.speedwaymotors.com/Industrial-Taps,3106.html

http://www.speedwaymotors.com/Industrial-Taps,3106.html

jerseyjeep01

NAXJA Forum User

- Location

- Berlin, New Jersey

I agree with Begster. Go to Ballistic Fab and get some tube adapters.

1980dg

NAXJA Forum User

- Location

- st marys wv

i wont beef all around how do i get that for a good price

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

Burger King,you can have it your way!

Begster

NAXJA Forum User

- Location

- Cape Cod/Boston, Mass

Define "good" price?

I have 1.5" OD x .25" wall DOM with the "1 ton" TRE's on my D44. I consider that beef.

I got the TRE's, threaded inserts, and enough DOM to make my tie rod, draglink, and track bar for just over $200.

I have 1.5" OD x .25" wall DOM with the "1 ton" TRE's on my D44. I consider that beef.

I got the TRE's, threaded inserts, and enough DOM to make my tie rod, draglink, and track bar for just over $200.

Im going to get 1.25" thick hex molybodenum soild and since Im a machinist it is 0 factor for me to make left hand and right hand threads without a tap especially with tap drill hole bigger than 1/2".

The tie rod will only cost me $40 in material and $0 for any additional items.

Thank you for the information on the thread size xjjeepthing.

I also stress tested it in a program that I have and the hex is stronger than round material in the factor that the way when a rock hits it the stess is distributed against a minimum of 2 surfaces instead of a rounded face.

The tie rod will only cost me $40 in material and $0 for any additional items.

Thank you for the information on the thread size xjjeepthing.

I also stress tested it in a program that I have and the hex is stronger than round material in the factor that the way when a rock hits it the stess is distributed against a minimum of 2 surfaces instead of a rounded face.

Begster

NAXJA Forum User

- Location

- Cape Cod/Boston, Mass

I also stress tested it in a program that I have and the hex is stronger than round material in the factor that the way when a rock hits it the stess is distributed against a minimum of 2 surfaces instead of a rounded face.

Yes, for matters in pure bending, two solid planes are better than a rounded surface, as you have a greater surface area to yield. But, you aren't always going to have that surface facing/coming into contact with the rocks/obstacles. I haven't run the numbers,and I'm not going to, but I'd trust the uniform shape of the round stock vs a corner of that hex. Either way, it should be plenty.

Sounds good. Ill take some.....Im going to get 1.25" thick hex molybodenum soild and since Im a machinist it is 0 factor for me to make left hand and right hand threads without a tap especially with tap drill hole bigger than 1/2".

The tie rod will only cost me $40 in material and $0 for any additional items.

Thank you for the information on the thread size xjjeepthing.

I also stress tested it in a program that I have and the hex is stronger than round material in the factor that the way when a rock hits it the stess is distributed against a minimum of 2 surfaces instead of a rounded face.

xj9140

NAXJA Forum User

- Location

- Sacramento, CA

Ya, but you don't want it stronger than the knuckle. I would rather bend a tie rod than break a knuckle.Yes, for matters in pure bending, two solid planes are better than a rounded surface, as you have a greater surface area to yield. But, you aren't always going to have that surface facing/coming into contact with the rocks/obstacles. I haven't run the numbers,and I'm not going to, but I'd trust the uniform shape of the round stock vs a corner of that hex. Either way, it should be plenty.

Begster

NAXJA Forum User

- Location

- Cape Cod/Boston, Mass

I have yet to see a broken knuckle. The tie rod end would break first.

asp

NAXJA Forum User

- Location

- Westport, MA

agreed.I have yet to see a broken knuckle. The tie rod end would break first.

depending on how much equipment is available to the OP and what his skill is, it's possible to cut threads on a lathe (even internal threads) so he wouldn't necessarily need to purchase the taps...

xcm

NAXJA Forum User

- Location

- Southern Oregon

you work in a machine shop but cannot measure a threaded peice of metal??

tgoff

NAXJA Forum User

- Location

- Eureka, CA

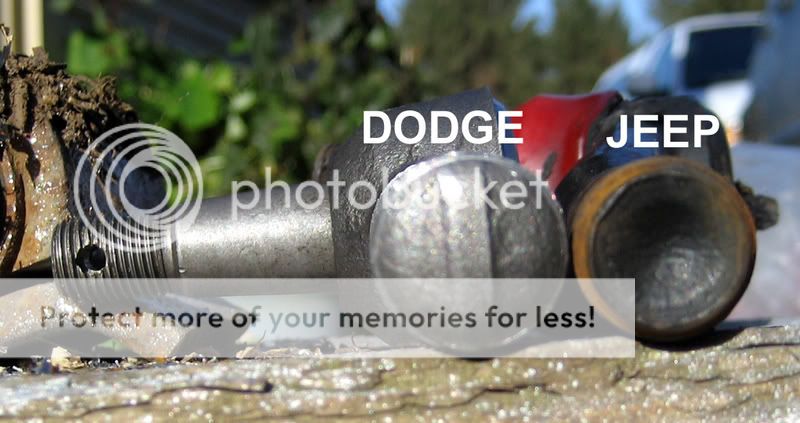

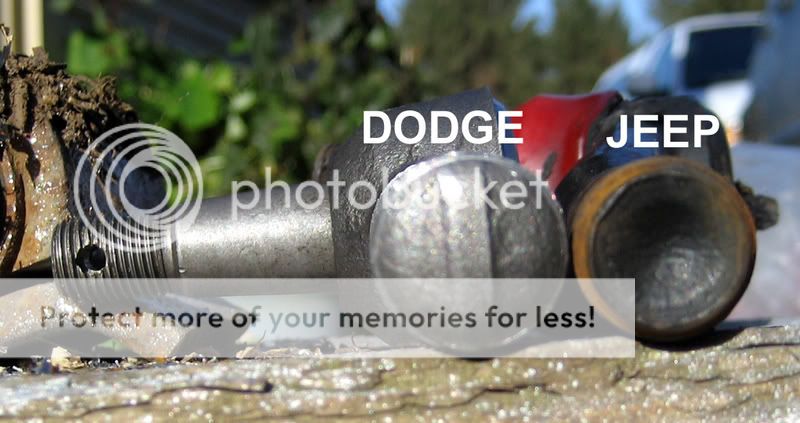

Just get some 1.5" OD .25" wall DOM and some threaded inserts. Use Dodge Ramcharger TRE's which have the same taper with a larger shank. Cost is pretty low and is what I did.

TRE comparison

Tie Rod Installed

Dodge TRE part numbers ES2847R ES2848R. For searching purposes use 1991 Dodge Ramcharger. Total cost to me was $100.

TRE comparison

Tie Rod Installed

Dodge TRE part numbers ES2847R ES2848R. For searching purposes use 1991 Dodge Ramcharger. Total cost to me was $100.

Similar threads

- Replies

- 9

- Views

- 855

- Replies

- 15

- Views

- 6K

- Replies

- 28

- Views

- 1K