IMO if you're going to build it from ground-zero, like you are, its worth doing everything in your power to get steering/track bar dialed.

Steps to get the axle placed (assuming you're not moving the steering box):

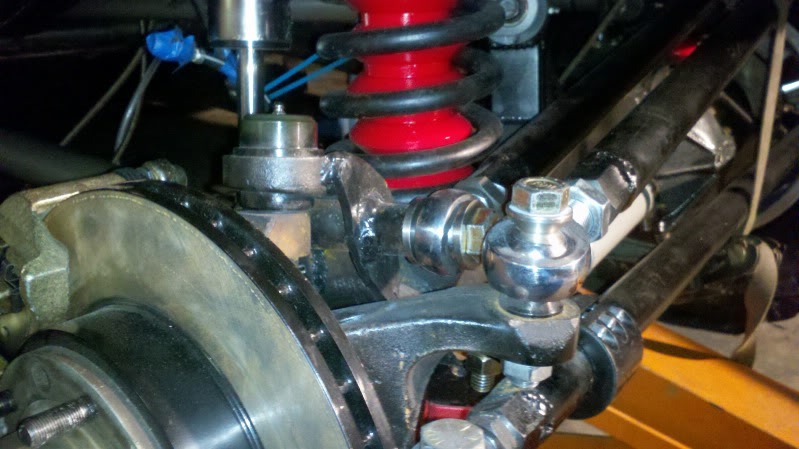

-Match your pitman arm length (throw, not drop) to your steering arm to get full range of steering travel. Also a good time to get the drag link as flat as you can at ride height (via drop pitman arm).

-Place axle such that the drag link is parallel to the axle. This should set your wheelbase. Doesn't have to be perfect, but getting this close will keep your ensure your steering is the same left and right.

-Place your coil buckets directly under the coil towers/bump stops at full bump. These may need to be offset forward/backward from the axle tube.

With the drag link and coils in place, you'll now see exactly how much room you have for your track bar. Definitely important to keep it parallel, but length is also important, and its a good idea to keep it close to the same height from the ground and generally centered with the drag link, but that's not too important and it could be argued keeping the track bar as high as possible is good because it keeps your roll center high and will reduce body roll.

I've seen a few examples of people mounting the axle side of the track bar on the inner C, which is a pretty cool solution. Keeps the pivots of the track bar as close to the drag link as possible which is ideal for reducing bump steer/flex steer under extreme conditions.

Most people seem to mount the track bar inside the passenger coil, and some go through the effort of extending the frame-side trackbar mount as far out as possible to minimize the length difference. This has worked out great for many people, but is a bit less elegant of a solution. Makes it tough to run a sway bar if you do that too.

Gonna be tough to tell until you get everything mocked up and start seeing the clearance yourself. FWIW, I haven't done this myself. Just been researching it for like 10 years while wheeling my junk with a poor setup. Got an axle on jack stands in the garage right now that will hopefully be under my rig come spring.