I finally got this done. I am pretty happy with it so far. On to the details, and LOTS of pics... To help the dial-upers they are all thumbnailed - click for the larger image obviously.

Also, I am a rookie fabber (hence doing the leafs) so feel free to make fun of my fabwork.

Out with the old:

Beginning the mockup for the front crossmember attachments:

For the passenger side, I drilled and welded in some tubing to keep from crushing the rail. I felt it wasn't necessary to use 3 bolts or to match the bolt locations of the driver side.

I basically stole the patented BrettM design by using 4x4x1/4 angle. The side and bottom peices are 1/4" plate. A little heat from the torch and the bottom peice bent like butter to properly catch the factory sway bar holes.

I pulled it off, welded it, and ground a radius between the side and bottom plates to make it look clean. I did kinda screw up here, notice that I left the 4x4 angle about a 1/4" wider than the side plates. I thought I needed this extra width for the front shackle mounts. As it turns out, I didn't. Had I flushed it all up, it would have looked a heck of a lot nicer.

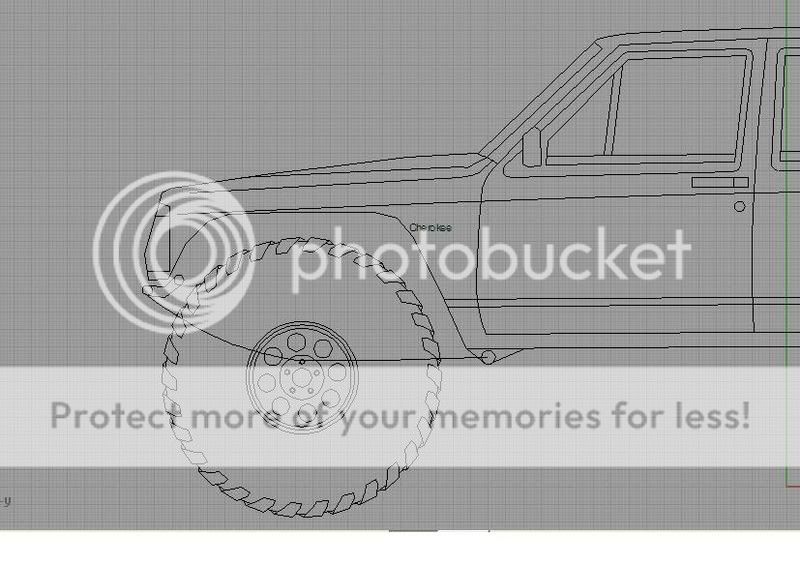

This was the first mockup attempt. Note, those are Rubicon Express 2.5" Extreme Duty (RE1432) mil-wrapped springs. Also, the original plan was to just use the factory LCA mount. However, notice that I whacked those off and made my own. At this point though, I was cursing myself because my mounts are basically in the stock LCA location. Nevertheless, I found that in this location, the axle was too far forward.

After several additional mockup attempts, this is where the rear mount ended up. My mounts were made out of 3.5" by 1/4" wall square tubing. Also, before I started on the front end I plated the frame rails with angle iron, I feel this proved key to making sure my rear mounts were solid. To add additional strength to the rear mount, I cut up some of that 4x4 angle, tied it to the frame rail angle and wrapped it around the mount.

To further strengthen the rear mount, I wanted to gusset it out. This also gave the mount a bit of a ramp to hopefully avoid getting hung up. The guesset is made out of 1/4" plate and was tied into the mount made out of box. After welding, it was ground and now looks as if it was all one peice.

With the rear mounts done, I moved on to finalizing the shackle mounts to hang off the front x-member.

Rear mounts painted up:

Front mounts and x-member painted up. I used stock length (4" i think) YJ shackles from RE.

With the springs in place, I moved to the axle. Of course, cutting and turning the knuckles. It really wasnt that hard. What worked quite well for me was a combination between a grinding wheel and a cut-off wheel. They were re-welded at about 4 degrees,

I wont go into detail about the spring perches, its easy enough. I got mopar d44 perches. For the driver side, I set the perch on the tube next to the cast ridge, drew a line and torched them out (if that makes sense). That way both of the perches sit at the same height. Of course, proper pre and post heat is absolutely key to making it stick on the cast side. Here is everything bolted up. A very small amount of grinding was done to fit the ubolt on that one side. Also, at this point the front x-member is completely bolted off with grade 8 and metric 8.8 hardware. 17 bolts total hold the front x-member onto the jeep.

Its past my bedtime, so I will discuss steering and what I had to do about shocks later. But, this is how it came out. It sits level with rubicon 4.5" springs + 1.75" shackle in the back.

-justin