redrider2911

NAXJA Forum User

- Location

- Yakima, WA

Alright guys, so I've been losing sleep over this for over a week now. This is the first post I've released about this new product Im hoping to release soon. Its still in the tweaking and design phase.

Background. So I honestly dont run a sway bar in the front of my rig but I know alot of people like to and disconnect them when they get to the trail. I personally started thinking about this for a rear coil conversion Im also hoping to release in the spring. The only reason I havent been running coils yet is because I didnt want the bad highway manners or worry about getting out and disconnecting the rusty sway bar links or running a suck down winch on side hills ect, ect.

So everyone probably know the new JKs and Rubicons come out with electric disco sway bars. You can find them at some online stores but expect to pay 1300 dollars or so. I've seen a couple in person and to me it looks like alot of moving parts just to slide over a collar right? So I decided that since most offroad vehicles have OBA (or hope to) or have a 12V air compressor that air would be the simpler, cleaner, and most importantly, cheaper way to go.

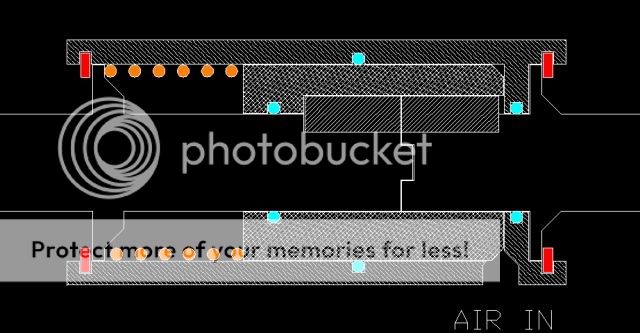

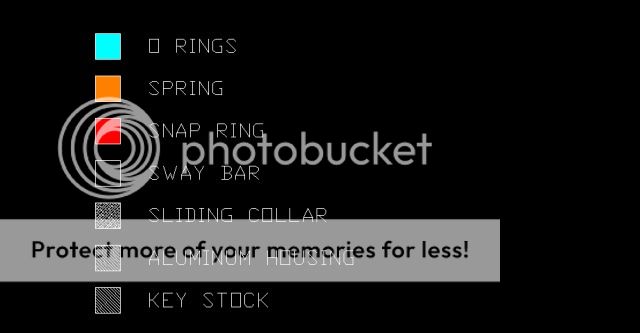

Basic Idea. The sway bar would have a left side and a right side. The 2 sides will be coupled together by a collar when engaged, spring loaded to seat into place locked even if there was some sort of failure (air line leak). When the air line is charged with the proper PSI it will slide the collar over off the splines and allow the 2 piece sway bar to move independently. When the air is released (blow off valve) the spring will push the collar back over the splines coupling to 2 pieces when properly lined up (on level ground). Of course this spring is heavy duty and stiff enough to slide the collar.

This will all be controlled by switches in the dash and would be able to run on an existing OBA system or a single 12V air compressor.

This is all I have time to right now. Let me know if you have questions and thoughts. I might be posting up some designs later for you guys to keep your interest.

Kris Froehlich

Background. So I honestly dont run a sway bar in the front of my rig but I know alot of people like to and disconnect them when they get to the trail. I personally started thinking about this for a rear coil conversion Im also hoping to release in the spring. The only reason I havent been running coils yet is because I didnt want the bad highway manners or worry about getting out and disconnecting the rusty sway bar links or running a suck down winch on side hills ect, ect.

So everyone probably know the new JKs and Rubicons come out with electric disco sway bars. You can find them at some online stores but expect to pay 1300 dollars or so. I've seen a couple in person and to me it looks like alot of moving parts just to slide over a collar right? So I decided that since most offroad vehicles have OBA (or hope to) or have a 12V air compressor that air would be the simpler, cleaner, and most importantly, cheaper way to go.

Basic Idea. The sway bar would have a left side and a right side. The 2 sides will be coupled together by a collar when engaged, spring loaded to seat into place locked even if there was some sort of failure (air line leak). When the air line is charged with the proper PSI it will slide the collar over off the splines and allow the 2 piece sway bar to move independently. When the air is released (blow off valve) the spring will push the collar back over the splines coupling to 2 pieces when properly lined up (on level ground). Of course this spring is heavy duty and stiff enough to slide the collar.

This will all be controlled by switches in the dash and would be able to run on an existing OBA system or a single 12V air compressor.

This is all I have time to right now. Let me know if you have questions and thoughts. I might be posting up some designs later for you guys to keep your interest.

Kris Froehlich