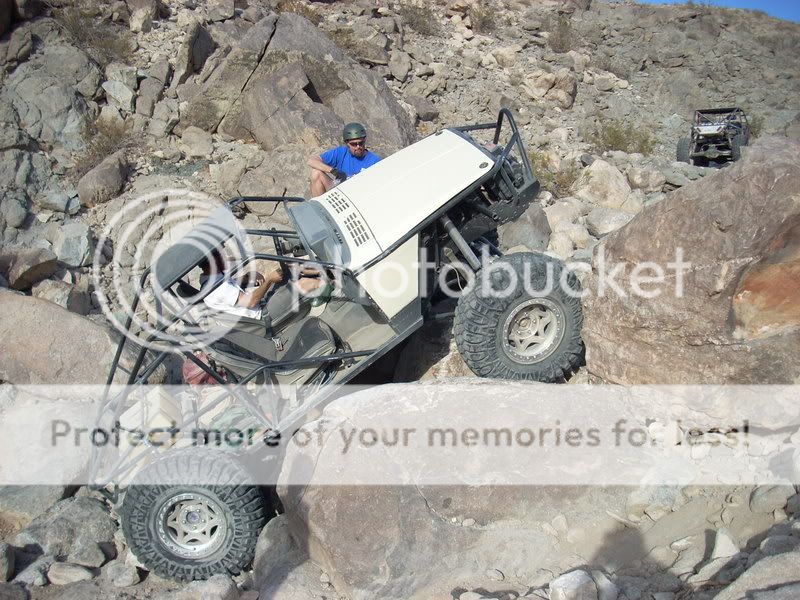

BTW, mega props to you guys for building very well designed cages. Easily strong enough and safe without all the roof tubes on the inside, adds quite a bit of rigidity, and protects the body in a roll so the rig isn't totalled. As an example, Santa rolled his and the rig was still totalled. He has a very good cage, and it did it's job of protecting him, but he had to build another rig. Granted, he did a bunch of endo's so who knows what any rig might have looked like, but with this design you at least have a fighting chance at not totalling the rig. By tying into the rock rails and having the roof halo on the outside, and having the grill hoop, you can roll and the rig can still survive. To me, the best posible design.