bhicks

NAXJA Forum User

- Location

- Forest Falls, CA

I think for me its more about, will it lay down a good bead a year from now, too...

Just get the 3 year extended warranty for like $30. I didn't go that route because I'm a cheap broke bastard.

I think for me its more about, will it lay down a good bead a year from now, too...

Just get the 3 year extended warranty for like $30. I didn't go that route because I'm a cheap broke bastard.

i still wouldnt waste the money on anything that didnt have gas accomodations, which the standard HF "mig" does not. i say "mig", because it isnt an actual mig, it's a wire feed. MIG means metal inert gas, which is impossible for it to be without being able to run gas. it isnt a quality issue, it's just missing that option entirely.yup, that's what I'm thinking about the welders themselves, too. Not to say that Miller, Hobart, and Lincoln aren't quality, awesome units, but I have seen first hand that the HF units will lay down a very, very nice bead on standard thickness mild steel.

I think, for me, its more about, will it lay down a good bead a year from now, too...

i still wouldnt waste the money on anything that didnt have gas accomodations, which the standard HF "mig" does not. i say "mig", because it isnt an actual mig, it's a wire feed. MIG means metal inert gas, which is impossible for it to be without being able to run gas.

flux core works ok for what it is, but once you go gas, you never go back...

for 300 you can get a nice used machine. the gas tank costs money too.No I totally get what you're saying. There's both on their website. One that's just fluxcore, and one that has the provisions to connect a regulator and hose making it a mig machine...

I'm looking @ this one that's about $300.00 and has provisions for the regulator:

http://www.harborfreight.com/120-amp-230-volt-mig-and-flux-welder-97503.html

No I totally get what you're saying. There's both on their website. One that's just fluxcore, and one that has the provisions to connect a regulator and hose making it a mig machine...

I'm looking @ this one that's about $300.00 and has provisions for the regulator:

http://www.harborfreight.com/120-amp-230-volt-mig-and-flux-welder-97503.html

for 300 you can get a nice used machine. the gas tank costs money too.

i got my lincoln with tank, nice regulator, and a cart for like 350. you're going to pay more for that harbor freight welder once you just add the tank. and then it's still a HF welder.....

not to mention, the used welder will always be worth at least what you paid for it, is worth repairing, and you can get replacement parts anywhere.

also, a regulator is not cheap. a HF one is about $35-40, and that is junk. a good victor one will run a lot more. also, a tank is not cheap initially. once you have it, it's not bad. that's why i would look for a used one with all that stuff on it already.

for 300 you can get a nice used machine.

that's a good deal!I paid that for my first welder with gas, cart, mask and some wire and tips.

Here's one...

http://inlandempire.craigslist.org/tls/2895559812.html

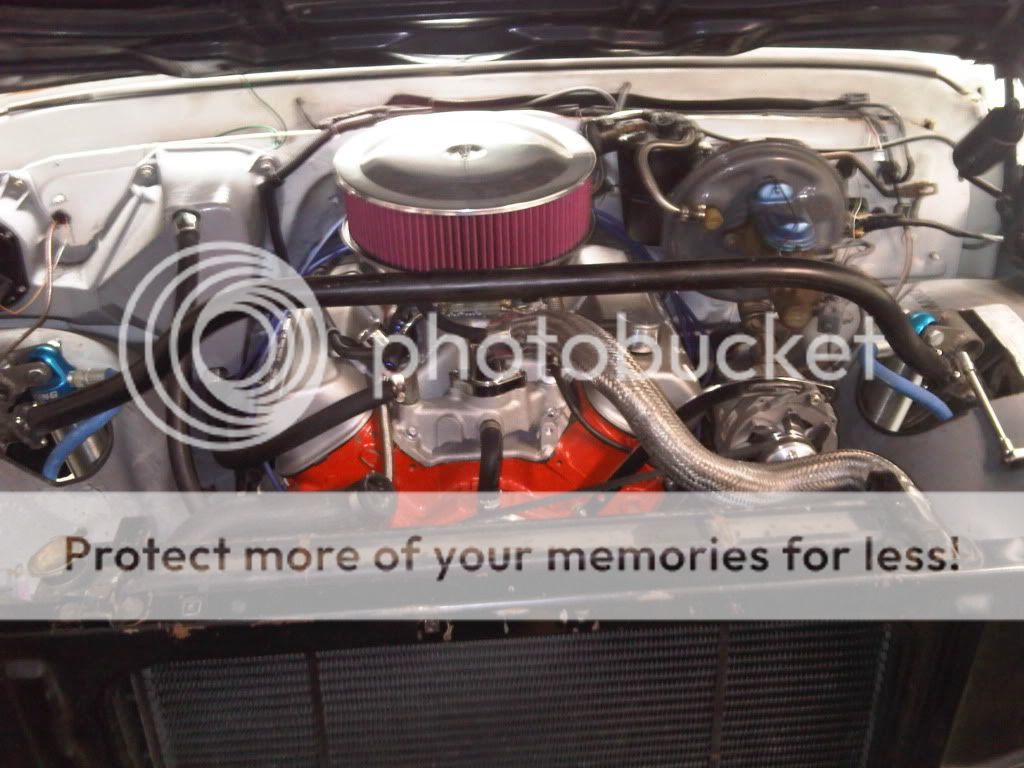

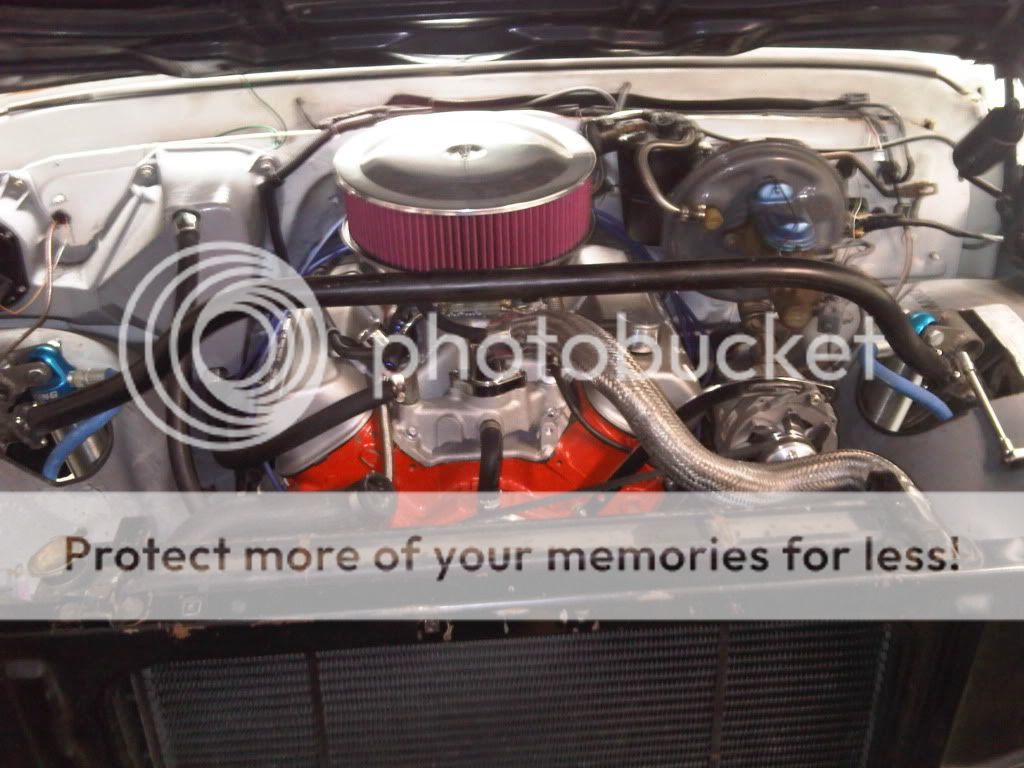

nice! now i'm jealous.Here's mine, got it for a G and I love it. Worth every penny, The auto set is awesome, You set the dial to what thickness you're welding and it does all the adjustments for ya.

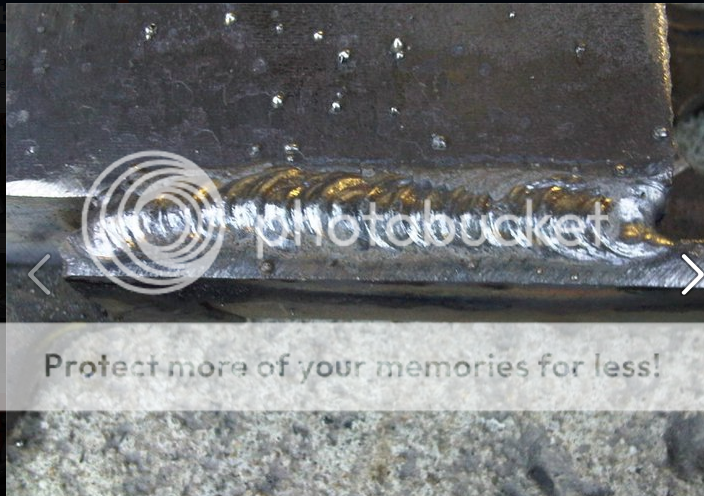

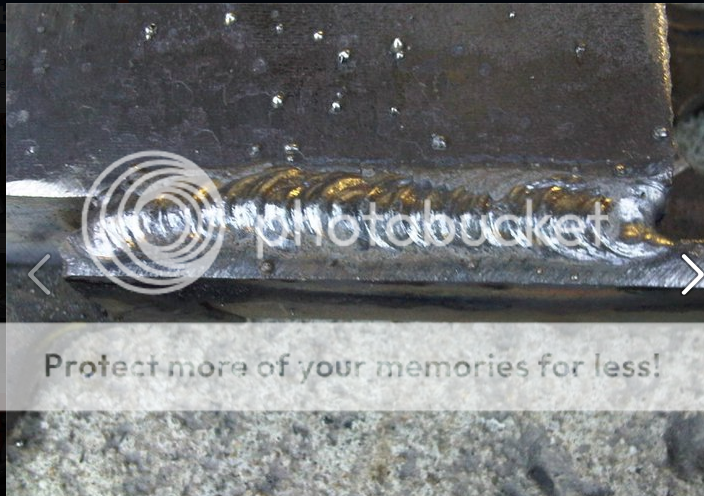

Here's a shot of a weld, .120 wall 2" sq tube to .250 plate. This is using the machines autoset, I did not clean any scale off or anything, just hooked the ground and started burning.

this is basically what i discovered after years of trial and error. kinda funny seeing it layed out like that, i almost thought i was the only one. i always have the heat cranked and the wire feed really low. when welding sheetmetal, i just adjust the wire feed, maybe a little off the voltage but not much.i started on one of these welders aabout 10 years ago ..and slowly i gained a lil know how .. use .35wire always .. it leaves u a bigger puddle for such a low volatage welder.. and always use the heat setting .. a lil higher at first .. or if yours is just 2 settings use the higher one with a kinda thick material .. or if ur using thin thin sheet metal use low ....

but here are my rules

1. use the .35 wire always

1. high heat if metal is kinda thick up to .120

3. keep the 2 metals u are welding really close to geather and very cleannn ..almost shiney THE cleaner the better" less spatter and uncontrable puddle

4.wire speed start at 2 and very . but adjust wire speed to how the weld sounds ... ur gonna wanna do some test welds first ...u want the weld spark to sound consistant . like other good welders can do really fast.. these welders take a lil time to heat the metal .if the spark sounds loud and the wire starts to bunch up .. the wire speed is to high .. if the wire is burning a hole in the material then its to low .. dont mess with heat range when this happens its usually a wire speed problem or your moving to fast ..when u got a good round spot test weld that looks like it is penatrating and not bubble

5.. when u start to weld ... start at the section that the 2 metals meet ..

6.pull the trigger all the way and start your weld.. but dont move the tip for about a seconed .. then move he wire feed into a constant slow circle makeing sure to start in the middle and make a slow circle that is 1/8 inch across each metal surfaces .. .like this

}8-8-8-8-8-8-8-8-8--<

thats how big u wanna make your circles.. the goal is to meet the two togeather but u just dont wanna go down the middle to make the smallest weld possible thats wat a tig is for . if its heated enough your final product will be weaker then if u make the weld wider going on to each piece it makes it twice as strong ..

here is weld from the same welder with .35 wire from lincoin innshield..

this is a solid motor mount for a big block chevy i make from 1' thick steel stock welded to 1/8 inch steel stock stamed motor mount shell

Here's mine, got it for a G and I love it. Worth every penny, The auto set is awesome, You set the dial to what thickness you're welding and it does all the adjustments for ya.

Here's a shot of a weld, .120 wall 2" sq tube to .250 plate. This is using the machines autoset, I did not clean any scale off or anything, just hooked the ground and started burning.

nice! now i'm jealous.

Most of the time the coupons for harbor freight do not apply to welders unless they specifically are for a certain welder.The link says $200. Toss a 20% off coupon on that and your at $160 for a great welder. Sounds like a great deal. Sometimes the instore people wont let you add a 20% coupon on a welder. If you go online and order it the shipping is $6.99 for anything to the end of the month and they will let you toss a 20% off coupon on anything.

I have the same machine and it is awesome. Worth every cent if you can come up with the money. You can also run smaller wire for thin materials.Here's mine, got it for a G and I love it. Worth every penny, The auto set is awesome, You set the dial to what thickness you're welding and it does all the adjustments for ya.

haha thanks, however if i try a nice machine, i will end up buying one, and i really shouldnt right now.Any friend of Kayles...

You can come play with my Miller anytime ya want. :wierd: