- Location

- San Diego

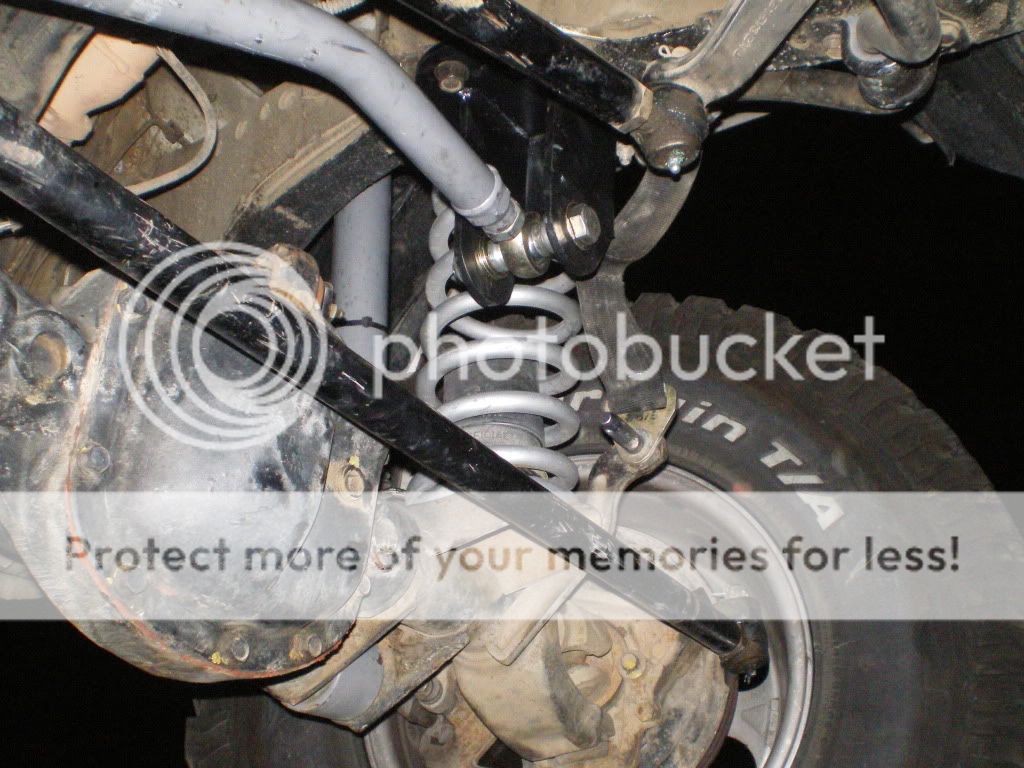

i used my single sheer RE 1600 track bar with the RE double sheer bracket. put in a new ruff stuff heim (direct replacement), drilled the RE mount out (to match 5/8" misalignment spacers), and have been loving it.

regardless of which mount you run, MOST are 2 5/8" wide to accept a standard JJ/cartridge style joint. i went with the RE bracket as it is only 2" wide, the same size as a misaligment spacer from ruff struff. if you plan to run heims, you will likely have to "space" the heim with washers like someone else posted on here. another option is the wider, 2 5/8" spacer that ruff stuff makes for their heims.

i did exactly that until i changed to my d44. still using the bracket, but i had to make a new track bar to work with the new axle.

worked fine, no issues.

I ran that setup for a long time. I went with the clayton bracket because they offered double shear with no drop and I didn't want to run a Drop pitman.

the only thing I wasn't crazy about is the OEM size bushing at the axle end. those tend to wear quickly and create a lot of problems.

I cut the factory bracket off the axle, built one to accept a 3/4" rod end with 9/16" misalignment spacers and have been happy since